Novel electrochemical polishing device and method

A polishing device and electrochemical technology, applied in the field of metal surface treatment, can solve problems such as affecting polishing quality and uneven polishing of workpieces, and achieve the effects of ensuring polishing effect, uniform roughness and brightness, and promoting ion diffusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Preparation of electrolyte solution 3: The formula composition of electrolyte solution 3 in the present invention includes the following components, wherein the content of each component and the preferred content of this embodiment are shown in Table 1: Table 1.

[0045] component name Content range This embodiment is preferred sodium hydroxide 10-30g / L 10g / L Sodium citrate 0.1-0.2mol / L 0.1mol / L Glycerol 10-20ml / L 10ml / L water Appropriate amount Appropriate amount

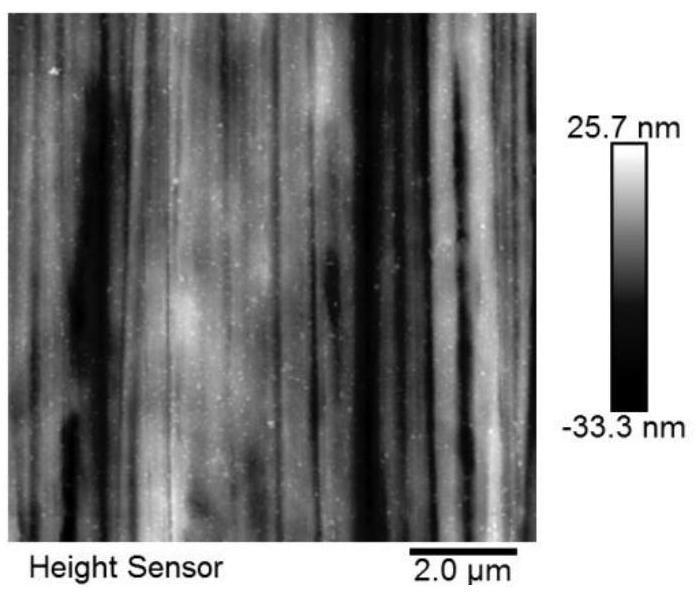

[0046] Pre-treatment before polishing: First, sand the tungsten workpiece to be polished to remove the surface oxide layer, then simply clean it with deionized water to remove the surface dust, and then use anhydrous ethanol in an ultrasonic cleaner to remove surface oil and attached particles, and then The surface is rinsed with deionized water to remove all impurities that can be rinsed away, and finally dried in a hot air stream. figure 2 The AFM imag...

Embodiment 2

[0051] Preparation of electrolyte solution 3: The formula composition of electrolyte solution 3 in the present invention includes the following components, wherein the content of each component and the preferred content of this embodiment are shown in Table 2: Table 2.

[0052] component name Content range This embodiment is preferred sodium hydroxide 10-30g / L 20g / L Sodium citrate 0.1-0.2mol / L 0.15mol / L Glycerol 10-20ml / L 20ml / L water Appropriate amount Appropriate amount

[0053] Processing method is as shown in embodiment 1;

[0054] Using the above electrochemical polishing parameters and the electrochemical polishing device, the tungsten workpiece obtained in this embodiment has uniform and low surface roughness. Measured by AFM, the roughness of both ends of the tungsten workpiece surface is 0.991nm and 0.943nm respectively, as shown in reference Figure 5 with Image 6 shown.

Embodiment 3

[0056] Preparation of electrolyte solution 3: The formula composition of electrolyte solution 3 in the present invention includes the following components, wherein the content of each component and the preferred content of this embodiment are shown in Table 3: Table 3.

[0057] component name Content range This embodiment is preferred sodium hydroxide 10-30g / L 30g / L Sodium citrate 0.1-0.2mol / L 0.2mol / L Glycerol 10-20ml / L 15ml / L water Appropriate amount Appropriate amount

[0058] Processing method is as shown in embodiment 1;

[0059] Using the above electrochemical polishing parameters and the electrochemical polishing device, the tungsten workpiece obtained in this embodiment has uniform and low surface roughness. Measured by AFM, the roughness of both ends of the tungsten workpiece surface is 0.757nm and 0.748nm respectively, as shown in reference Figure 7 with Figure 8 shown.

[0060] Working principle of the prese...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com