Core-shell chain-shaped nickel-based selenide/iron oxyhydroxide composite catalyst as well as preparation method and application thereof

A technology of iron oxyhydroxide and composite catalyst, which is applied in the direction of electrolysis components, electrodes, electrolysis process, etc., can solve the problems of poor conductivity of iron oxyhydroxide alone, and achieve the effect of improving OER performance, reducing cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

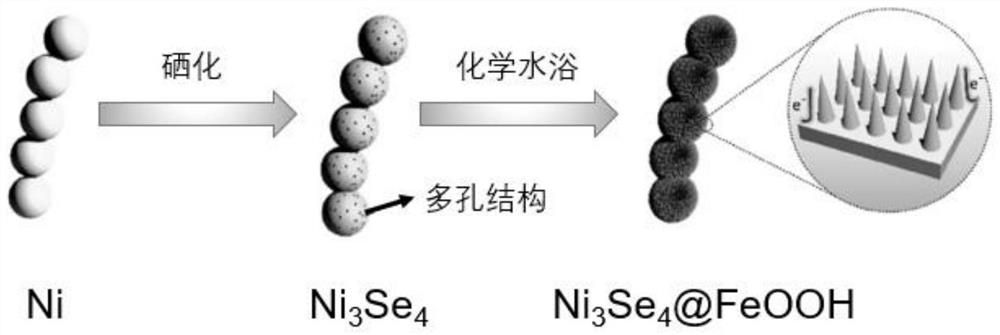

[0039] A preparation method of a core-shell chain nickel-based selenide / iron oxyhydroxide composite catalyst, specifically comprising the following steps:

[0040] (1) Preparation of nickel-based metal core-shell chain nanomaterials: Dissolve 0.5mmol nickel(II) acetylacetonate in 45ml ethylene glycol, then slowly add 1ml85% hydrazine hydrate; stir the solution for 5min to mix evenly, then transfer to 80ml In an autoclave, heat to 180°C for 8h; collect the product after cooling, wash with deionized water and absolute ethanol three times, and then vacuum dry at 60°C for 10h to obtain a nickel-based metal core-shell chain nanomaterial;

[0041] (2) Selenization treatment of nickel-based metal core-shell chain nanomaterials: add 7.5mmol selenium powder, 15mmol sodium hydroxide and 50ml N,N-dimethylformamide into an 80ml autoclave, stir vigorously for 15min, then add 0.3ml Hydrazine hydrate; then add 20 mg of nickel-based metal core-shell chain-like nanomaterials and mix well, heat...

Embodiment 2

[0044] A preparation method of a core-shell chain nickel-based selenide / iron oxyhydroxide composite catalyst, specifically comprising the following steps:

[0045] (1) Preparation of nickel-based metal core-shell chain nanomaterials: 0.4mmol nickel acetylacetonate (II) was dissolved in 40ml ethylene glycol, then slowly added 0.5ml85% hydrazine hydrate; after the solution was stirred for 5min to mix evenly, transferred to In an 80ml autoclave, heat to 180°C for 8h; collect the product after cooling, wash with deionized water and absolute ethanol three times respectively, and then vacuum dry at 60°C for 10h to obtain a nickel-based metal core-shell chain nanomaterial;

[0046] (2) Selenization treatment of nickel-based metal core-shell chain nanomaterials: Add 6mmol selenium powder, 14mmol sodium hydroxide and 40ml N,N-dimethylformamide into an 80ml autoclave, stir vigorously for 15min, then add 0.2ml hydration Hydrazine; then add 10 mg of nickel-based metal core-shell chain nan...

Embodiment 3

[0049] A preparation method of a core-shell chain nickel-based selenide / iron oxyhydroxide composite catalyst, specifically comprising the following steps:

[0050] (1) Preparation of nickel-based metal core-shell chain-shaped nanomaterials: Dissolve 0.6mmol nickel(II) acetylacetonate in 50ml ethylene glycol, then slowly add 2ml85% hydrazine hydrate; stir the solution for 5min to mix evenly, then transfer to 80ml In an autoclave, heat to 180°C for 8h; collect the product after cooling, wash with deionized water and absolute ethanol three times, and then vacuum dry at 60°C for 10h to obtain a nickel-based metal core-shell chain nanomaterial;

[0051] (2) Selenization treatment of nickel-based metal core-shell chain nanomaterials: add 9mmol selenium powder, 16mmol sodium hydroxide and 60ml N,N-dimethylformamide into an 80ml autoclave, stir vigorously for 15min, then add 0.4ml hydration Hydrazine; then add 50 mg of nickel-based metal core-shell chain nanomaterials and mix well, he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com