A kind of nozzle hole sealing material and preparation method and sealing method thereof

A technology of sealing materials and holes, which is applied in the field of materials, can solve problems such as difficulty in demolition, weakening of stress, loss of sealing effect, etc., and achieve the effect of simplifying construction operations and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

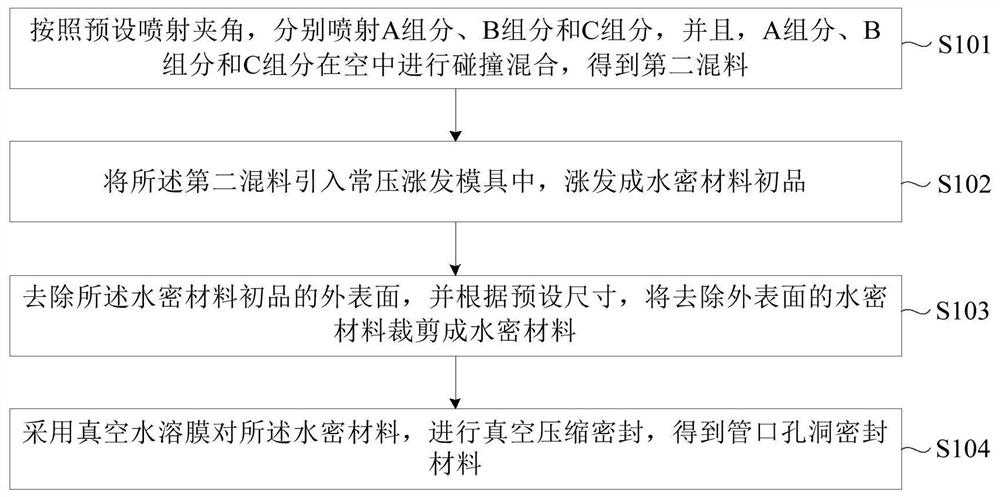

Method used

Image

Examples

preparation example Construction

[0069] In the present embodiment, optionally, the preparation method of component A includes:

[0070] Add the polymer polyol, pore-opening aid, water, flame retardant and catalyst into the mixing equipment and mix evenly to obtain the first mixture;

[0071] The first mixture is added to a pressurized container filled with liquid carbon dioxide, and mixed to obtain component A.

[0072] In the specific implementation, the polymer polyol, pore-opening aid, water, flame retardant, and catalyst are added to the mixing equipment, and stirred at a stirring speed of 400-800 R / min to obtain the first mixture, and then the first mixture is mixed. Add it into a pressurized container containing liquid carbon dioxide, pressurize the pressurized container, and keep the pressure value in the pressurized container at 4-6 MPa to obtain component A. Another convenience, the specific method for realizing the full mixing of the A component, also includes: when the A component needs to be spra...

preparation example 1

[0079] Preparation Example 1 (adding according to specific quality)

[0080] 60 g of polyoxypropylene triol with a hydroxyl value of 33 mgKOH / g and a number-average molecular weight of 4800, 2 g of stearyloxydimethylsilane, 1 g of water, 25 g of tris(2-chloropropyl) phosphate, and 3 g of stannous octoate Add it to the mixing equipment, and stir at a stirring speed of 600R / min to make it evenly mixed to obtain the first mixture;

[0081] The obtained first mixture was added to a pressurized container containing 9 g of liquid carbon dioxide, and the pressure was continued to 5 MPa, and mixed to obtain A component No. 1.

preparation example 2

[0082] Preparation Example 2 (feeding by weight percentage)

[0083] The polyether polyol 330N (manufacturer: Shandong Dongdayi Novi) 66.3%, the opening aid Y1900 (manufacturer: South Korea SKC company) 1%, water (self-made), flame retardant dmmp (manufacturer Qingdao Lianmei Chemical) 20%, catalyst A33 (manufacturer: Xindian Chemical Materials (Shanghai) Co., Ltd.) 1.5%, stannous octoate (manufacturer: Xindian Chemical Materials (Shanghai) Co., Ltd.) 0.2%, added to the mixing equipment, at 400R / min Stir at the stirring speed to make it evenly mixed to obtain the first mixture;

[0084] The obtained first mixture was added to a pressurized container containing 10% liquid carbon dioxide (manufacturer: Langfang Liming Gas Co., Ltd.), continued to be pressurized to 4 MPa, and mixed to obtain A component No. 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com