Improved synthesis method of cosmetic active ingredient boehine

A technology of active ingredient and boson, which is applied in the field of improved synthesis of boson, an active ingredient in cosmetics, can solve the problems of increasing the difficulty of enlargement of the process, unable to control the reduction product, and difficult to completely react completely, and achieve a good reaction effect. , Improve the efficiency of process research and development, and reduce the effect of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

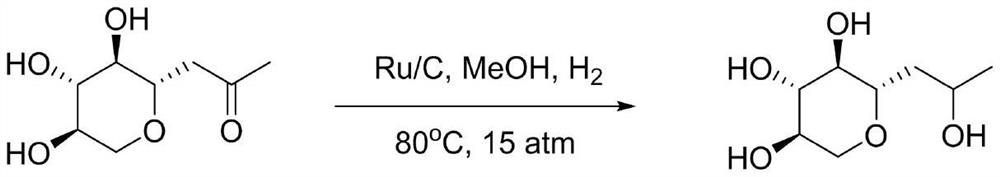

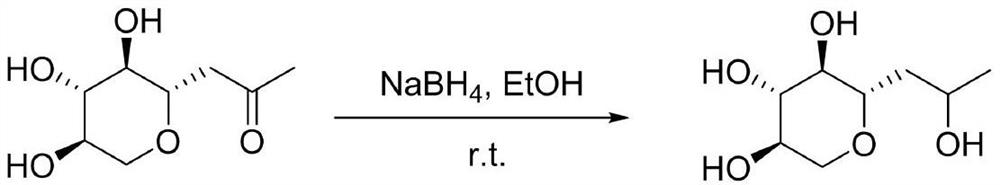

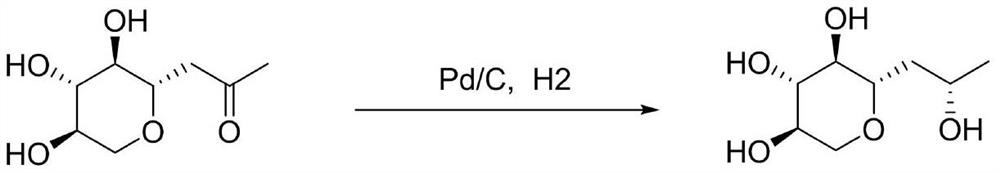

Image

Examples

Embodiment 1

[0032] Weigh 190g of 1-((2S,3R,4S,5R)-3,4,5-trihydroxytetrahydro-2H-pyran-2-yl)propan-2-one and dissolve it in 1L of methanol, stir to dissolve, Then inject it into the preheating module and preheat to 70°C; set the palladium carbon filling volume to 5mL, the particle size to 0.5mm, and the pressure to 5atm, and then control the H 2 The feed flow rate is 30 sccm; N 2 The feed flow rate is 65 sccm, and finally the preheated 1-((2S,3R,4S,5R)-3,4,5-trihydroxytetrahydro-2H-pyran-2-yl)propan-2-one solution Inject into the preheated reaction module at a feed flow rate of 0.8mL / min. Collect the effluent reaction solution (sampling test, nuclear magnetic external standard calculation contains 178g of product, TLC shows that the raw material is obviously left), spin dry the solvent methanol, beat with 480mL petroleum ether / 2-methyltetrahydrofuran (volume ratio 12 / 1) for 1h, and suction filter A white solid was obtained, and 162 g of the product was obtained by drying, the yield was 8...

Embodiment 2

[0034] Weigh 190g of 1-((2S,3R,4S,5R)-3,4,5-trihydroxytetrahydro-2H-pyran-2-yl)propan-2-one and dissolve it in 1L isopropanol, stir to dissolve Then inject it into the preheating module and preheat to 70°C; set the loading amount of palladium carbon to 5mL, the particle size to 0.5mm, and the pressure to 5atm, and then control the H 2 The feed flow rate is 30 sccm; N 2 The feed flow rate is 65 sccm, and finally the preheated 1-((2S,3R,4S,5R)-3,4,5-trihydroxytetrahydro-2H-pyran-2-yl)propan-2-one solution Inject into the preheated reaction module at a feed flow rate of 0.8mL / min. Collect the effluent reaction solution (sampling test, NMR external standard calculation contains 190g of product, TLC shows no raw material remaining), spin-dry the solvent isopropanol, 480mL petroleum ether / 2-methyltetrahydrofuran (volume ratio 12 / 1) mixed solvent beating for 1h , a white solid was obtained by suction filtration, and 188 g of product was obtained by drying, the yield was 98%, and th...

Embodiment 3

[0038]Weigh 190g 1-((2S,3R,4S,5R)-3,4,5-trihydroxytetrahydro-2H-pyran-2-yl)propan-2-one and dissolve it in 500mL isopropanol, stir to dissolve Then inject it into the preheating module and preheat to 70°C; set the loading amount of palladium carbon to 5mL, the particle size to 0.5mm, and the pressure to 5atm, and then control the H 2 The feed flow rate is 30 sccm; N 2 The feed flow rate is 65 sccm, and finally the preheated 1-((2S,3R,4S,5R)-3,4,5-trihydroxytetrahydro-2H-pyran-2-yl)propan-2-one solution Inject into the preheated reaction module at a feed flow rate of 0.8mL / min. The effluent reaction solution was collected and sampled for detection. TLC showed that a large amount of raw materials remained, and the NMR external standard method estimated that it contained 106g of product, with a yield of 55%. The R / S configuration ratio after carbonyl reduction was 48 / 52.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com