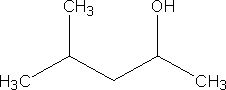

Preparation method of 4-methyl-2-pentanol

A technology of pentanol and methyl, which is applied in the field of preparation of 4-methyl-2-pentanol, can solve the problems of high reaction temperature and insufficient product purity, achieve high yield, broad application prospects, mild and safe reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a preparation method of 4-methyl-2-pentanol, which comprises the following process: first put mesityl oxide into a hydrogenation kettle, then add a nickel-containing three-way catalyst, feed hydrogen gas under stirring, and carry out catalytic hydrogenation. Hydrogen reaction, after the reaction, the catalyst is filtered off, and the filtrate is separated by distillation to obtain 4-methyl-2-pentanol.

[0024] specifically:

[0025] The nickel-containing three-way catalyst is AlNiFe, AlNiZn, AlNiCu, AlNiCo or AlNiMo.

[0026] The mass ratio of the above-mentioned mesityl oxide to the three-way catalyst is 1:0.02-0.1.

[0027] The hydrogen pressure of the above-mentioned catalytic hydrogenation reaction is controlled at 20-60KG.

[0028] The preparation method of the above-mentioned 4-methyl-2-pentanol includes the following specific process: put mesityl oxide into a hydrogenation kettle, then add a nickel-containing three-way catalyst, close the...

Embodiment 1

[0031] Put 50g of mesityl oxide into the hydrogenation kettle, add 5g of alnico, seal the hydrogenation kettle, replace with nitrogen three times, add hydrogen to 60KG pressure, start stirring, and heat to react. When the temperature of the material is 30-100°C, the reaction will release heat When the initial material temperature is 30-60°C, the hydrogen pressure is controlled at 20-60KG for the reaction; when the later material temperature is 80-100°C, the hydrogen pressure is controlled at 40-60KG for the reaction until no more hydrogen is absorbed. 80-100°C, hydrogen pressure controlled at 50-60KG, heat preservation for 2 hours, sampling analysis: product content > 99%, the reaction is complete, stop stirring, let stand, release the pressure, absorb the upper liquid, heat and distill, collect 128 The product at -130°C is 4-methyl-2-pentanol, and 47g of 4-methyl-2-pentanol is obtained, with a content of 99.8% and a yield of 93.8%.

Embodiment 2

[0033] Put 50g of mesityl oxide into the hydrogenation kettle, add 2.5g of alnico, seal the hydrogenation kettle, replace with nitrogen three times, add hydrogen to 60KG pressure, start stirring, and heat for reaction. When the temperature of the material is 30-100°C, the reaction will release heat. When the initial material temperature is 30-60°C, the hydrogen pressure is controlled at 20-60KG for the reaction. In the later stage, the material temperature is 80-100°C, and the hydrogen pressure is controlled at 40-60KG for the reaction. When the hydrogen is no longer absorbed, the material temperature is 80-100°C, hydrogen pressure controlled at 50-60KG, heat preservation for 2 hours, sampling analysis: product content ›99%, the reaction is complete, stop stirring, let stand, release the pressure, absorb the upper liquid, heat and distill, collect 128- The product at 130° C. is 4-methyl-2-pentanol, and 45 g of 4-methyl-2-pentanol is obtained, with a content of 99.6%, and a yiel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com