All-position gas shielded flux-cored wire downward semi-automatic welding method for long-distance pipeline

A semi-automatic welding and flux-cored welding wire technology, applied in welding equipment, welding medium, welding equipment, etc., can solve the problems of non-metallic inclusion residue, weld impact toughness reduction, weld toughness instability, etc., to reduce sensitivity High resistance, high weld impact performance, and the effect of reducing the risk of weld cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

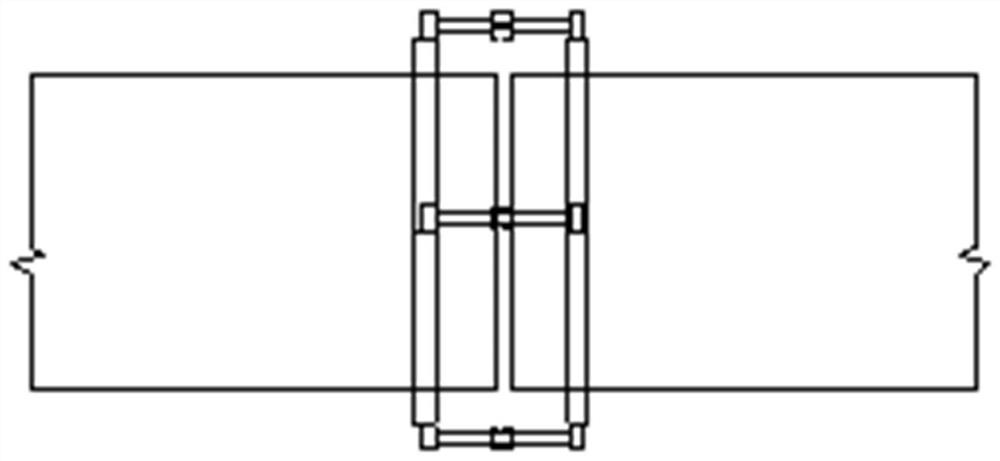

[0045] Operation steps: Groove processing (multiple groove forms)—weld seam pairing (external counterpart pairing)—root welding (argon tungsten arc welding)—filler cap welding (under gas-shielded basic flux-cored wire to semi-automatic welding).

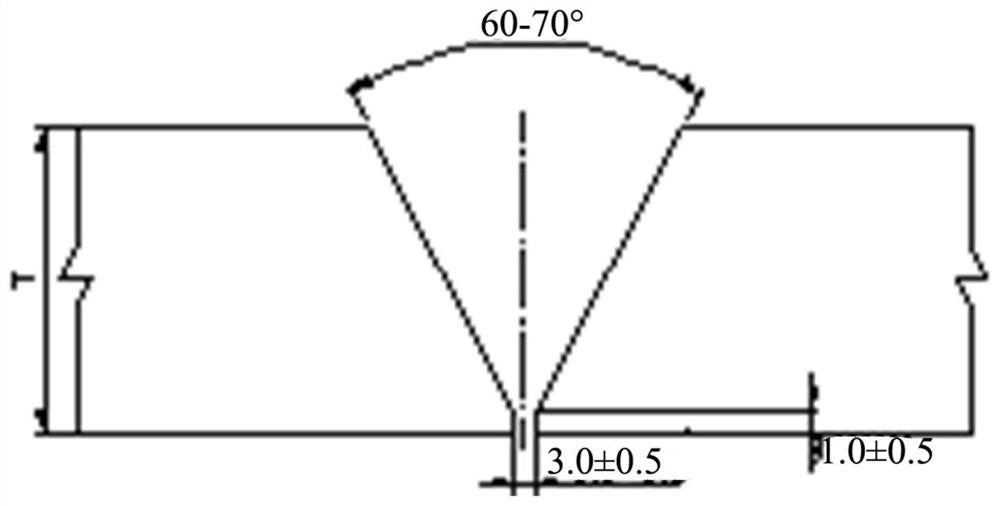

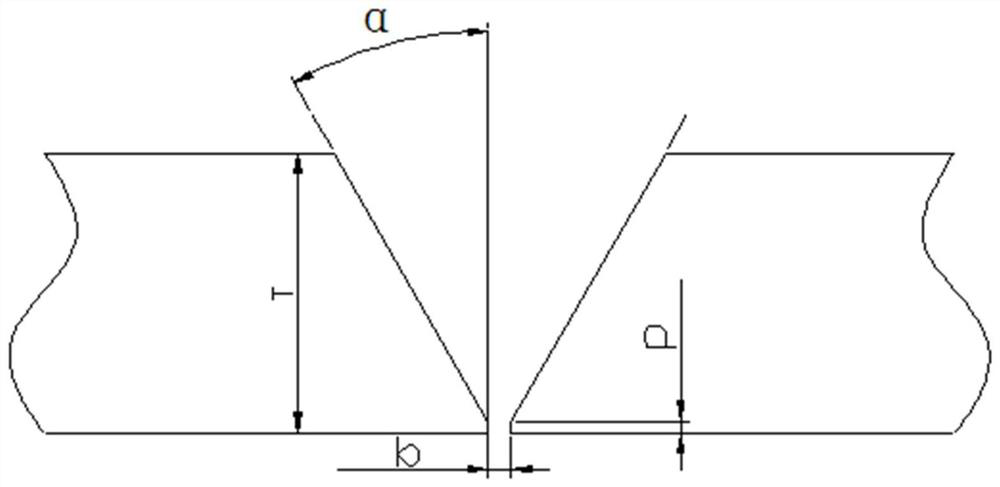

[0046] Groove processing: The groove is mainly used to weld the workpiece and ensure the welding quality. According to the welding requirements of different sections of the long-distance pipeline, different bevel forms are selected for the long-distance pipeline for groove processing. Take the following two groove forms as examples:

[0047] (1) V-shaped groove: The structural diagram of the V-shaped groove is as follows image 3 As shown, among them, T is the wall thickness, the value range is above 8mm; α is the groove degree, the value range is 24°~26°; p is the blunt edge, the value range is 0~2.5mm; b is the counterpart Clearance, the value range is 2.5 ~ 4.0mm.

[0048] (2) Composite groove: The structural diagram of the com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com