Method for producing chiral drug

A technology for chiral drugs and drug groups, applied in separation methods, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of inability to complete the discharge, long production process, large space occupation, etc., to simplify the production process, The effect of reducing the production process and improving the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, not to limit the present invention.

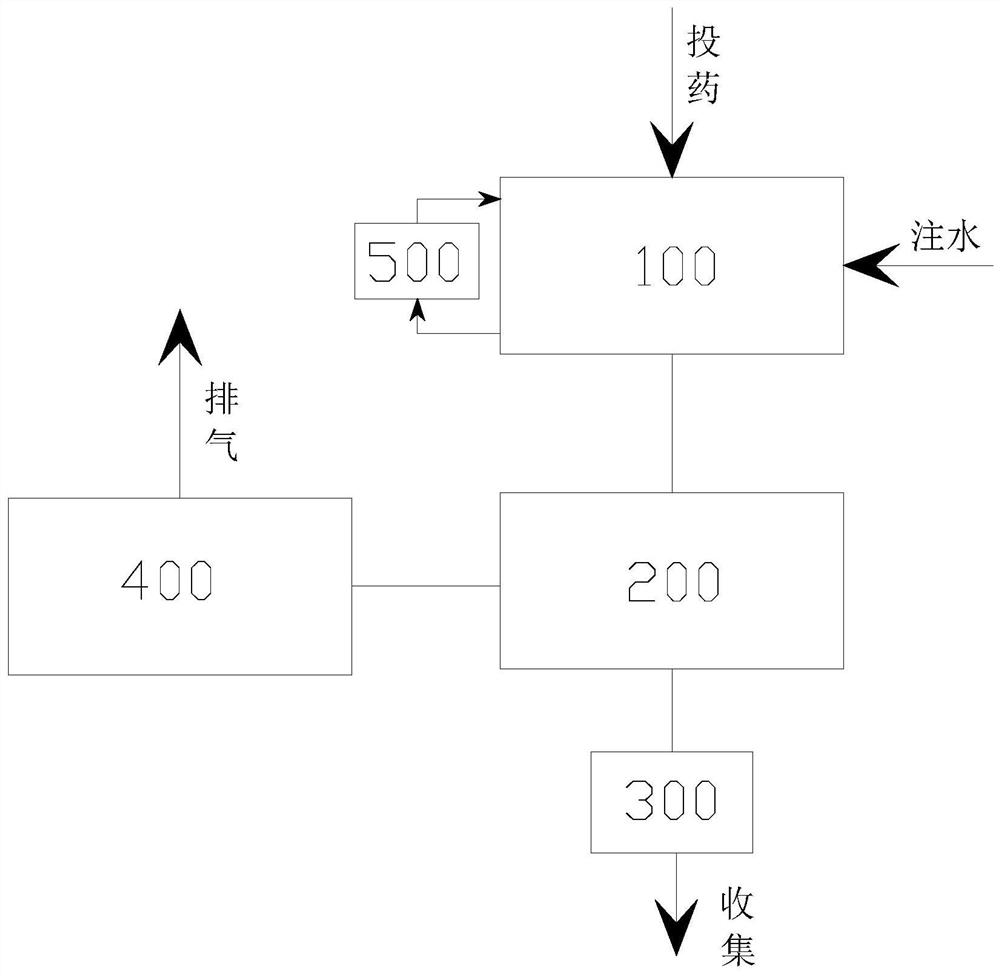

[0058] A method for producing chiral drugs, comprising the steps of:

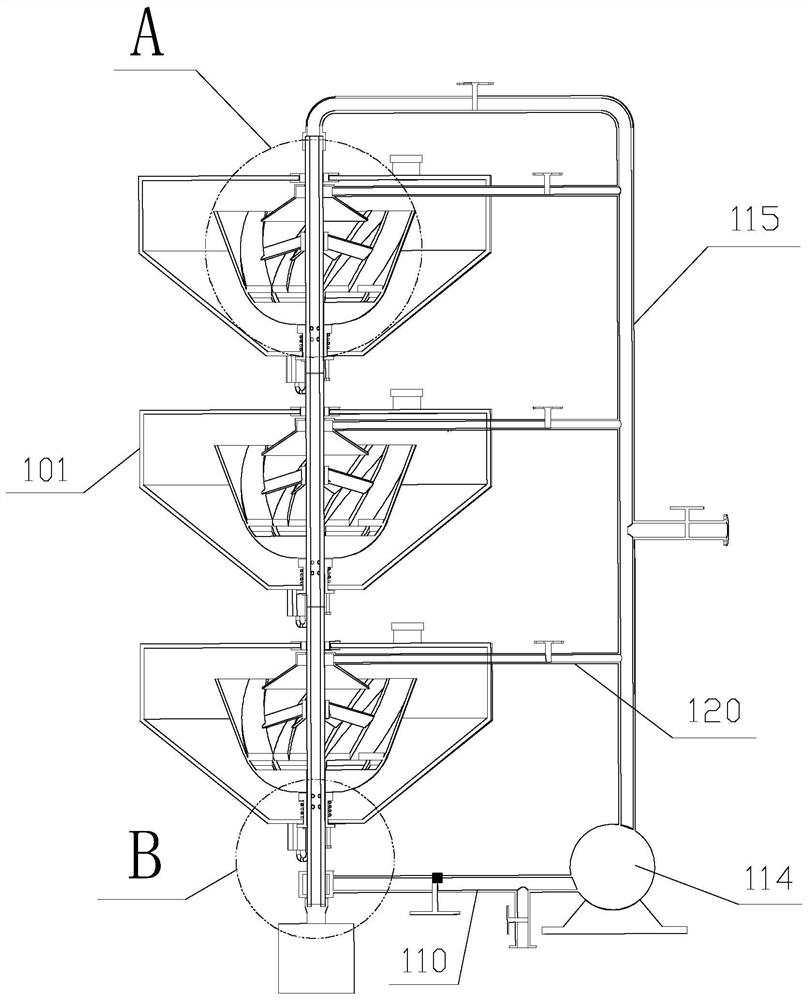

[0059] S1. Divide the components for the production of chiral drugs into multiple drug groups according to requirements, and put these drug groups into the corresponding reaction kettles 101 of the mixing reaction device 100;

[0060] S2, open the on-off mechanism at each reaction kettle, inject reaction water into the reaction kettle 101 through the circulation pump 114, and in the process of water injection, the variable frequency drive motor 108 continues to drive the material pipe 105 to make it rotate;

[0061] S3. According to the different water demand of the reaction water in each reactor 101, close the corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com