Battery, electric appliance and battery production data tracing method

A battery and electrode assembly technology, applied in secondary batteries, lithium storage batteries, electrochemical generators, etc., can solve the problems of poor traceability of lithium ion batteries, difficulty in locking abnormal batches, affecting production efficiency, etc., and is conducive to production. The effect of management, traceability, and production efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

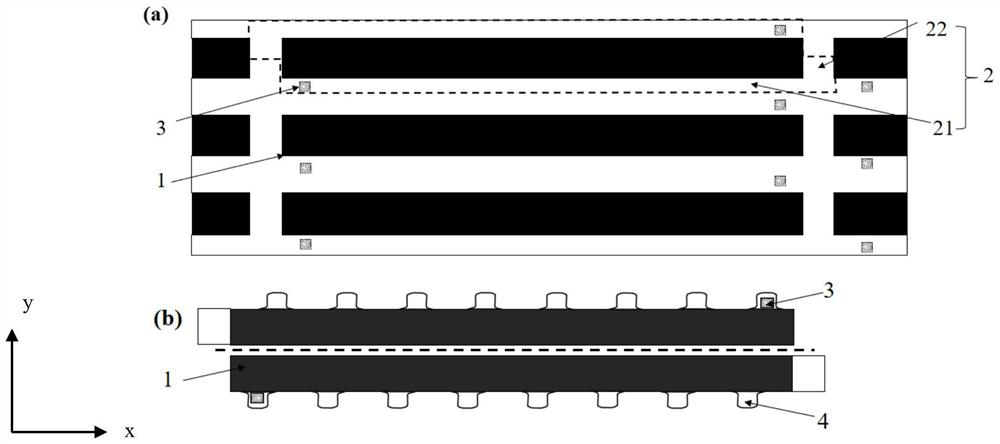

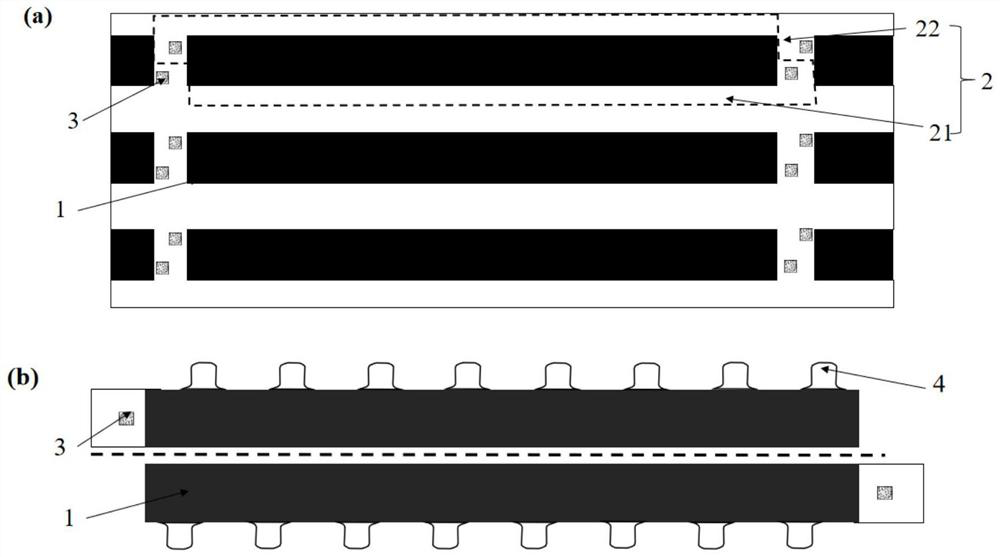

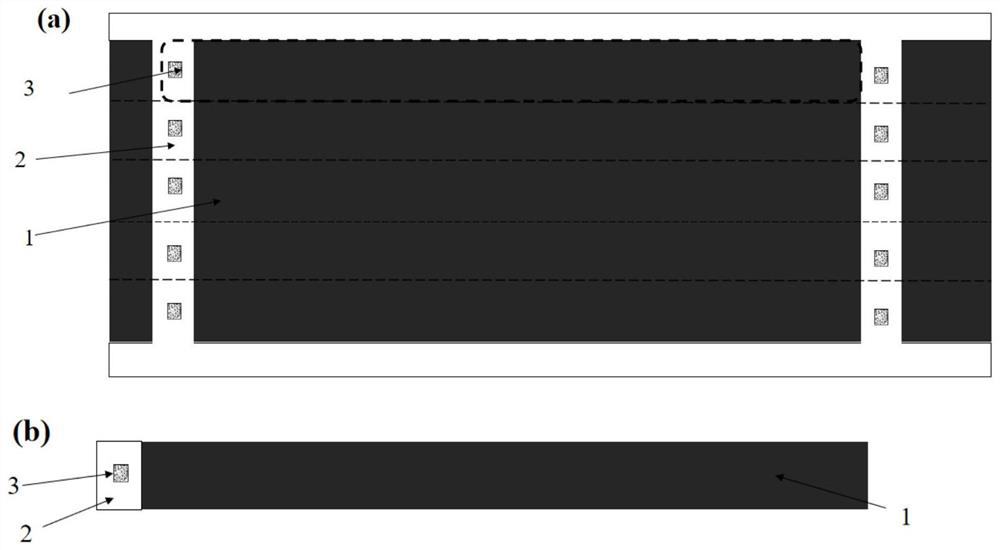

Image

Examples

Embodiment Construction

[0040] In the manufacturing process of lithium-ion batteries, the quality of raw materials and the control of each process have a great impact on the quality of the final finished battery. Moreover, there are many processes in the manufacturing process of the lithium-ion battery, and adverse problems may occur in the manufacturing of each process. Defective problems may be caused by unqualified raw materials supplied by upstream material suppliers, or unqualified back-end process processing and assembly. At present, the production process of lithium batteries is mainly traced through the battery bar code, and it is difficult to obtain the data information of the raw materials that make up the battery cells and the positive and negative electrodes accurately and quickly. If the quality of the finally manufactured lithium-ion battery is abnormal, analysis by some conventional methods has great limitations. On the one hand, it is difficult to accurately determine whether it is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com