Composite thermoelectric material crystal ingot and preparation method and application thereof

A technology for thermoelectric materials and crystal ingots, applied in the field of material engineering, can solve problems such as segregation of impurity elements that have not yet been solved, and achieve the effects of reasonable microstructure, good composition uniformity and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] An embodiment of the present invention provides a method for preparing the above-mentioned composite thermoelectric material crystal ingot, comprising:

[0044] Will Cu 2 Te and Bi 2 Te 3 Placed in the melting temperature zone of the heating device to make Bi 2 Te 3 melts and makes Cu 2 Te dissolves in Bi 2 Te 3 in the melt;

[0045] Then the dissolved Cu 2 Bi of Te 2 Te 3 The melt moves from the melting temperature zone to the solidification temperature zone of the heating device to solidify the melt into an ingot.

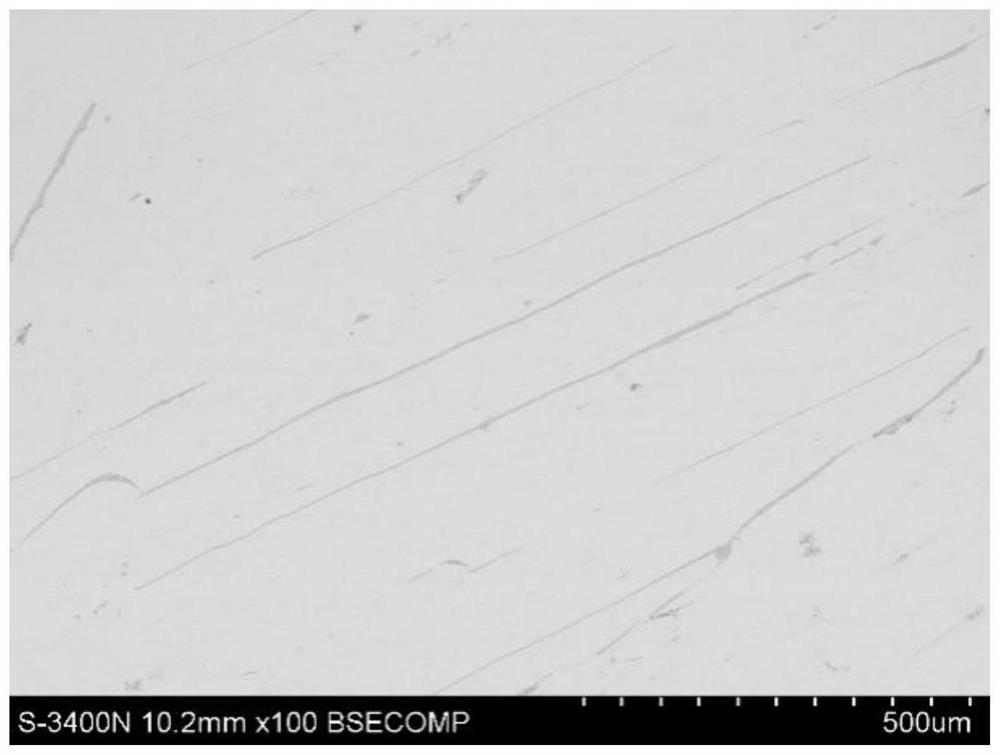

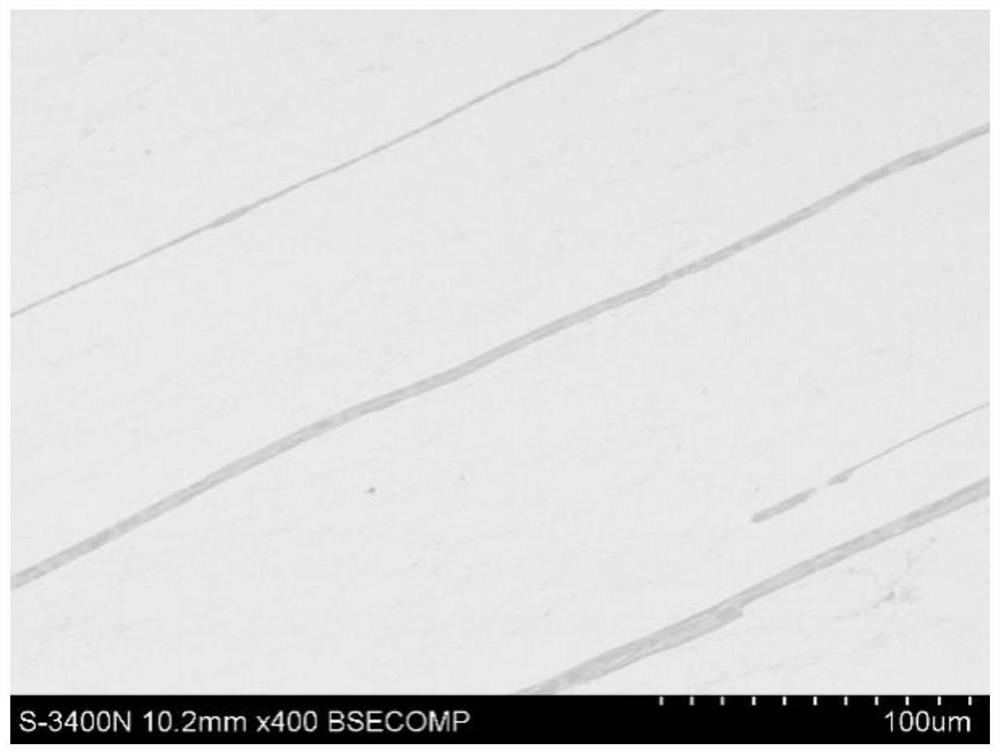

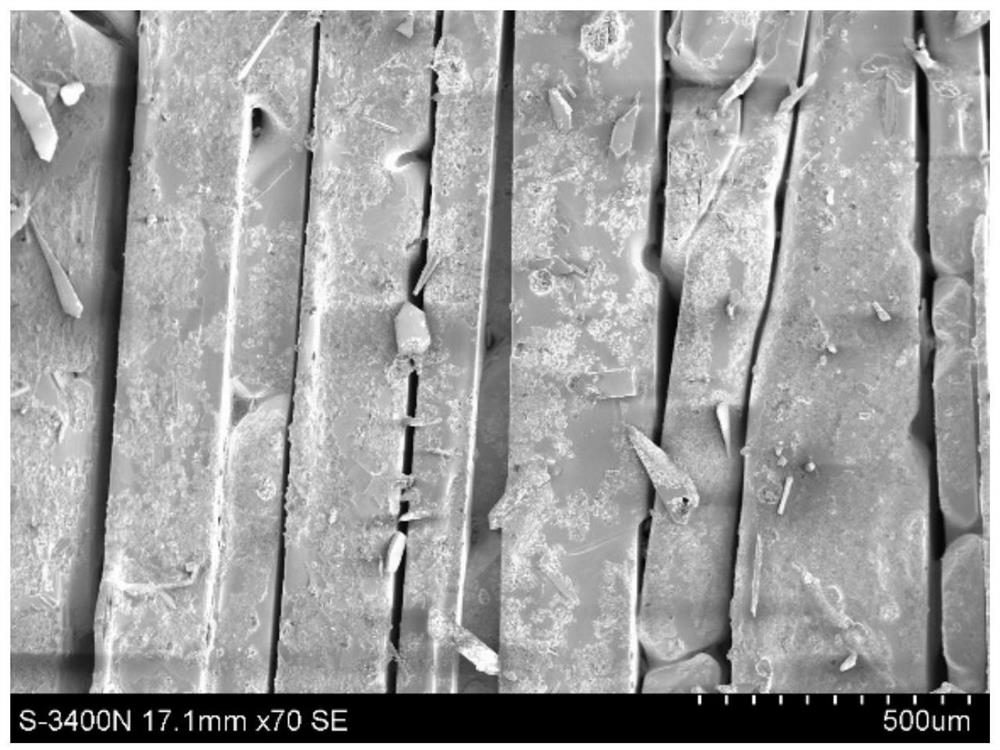

[0046] The above method makes the melt solidify in the direction opposite to the heat flow (that is, the direction from the solidification temperature zone to the melting temperature zone) as the solidification direction, located at Bi 2 Te 3 The copper-rich phase between (Cu) sheets is formed during the solidification process. The copper in the liquid phase mainly diffuses in a short distance perpendicular to the growth direction, and the diff...

Embodiment 1

[0063] This example uses Cu 2 Te and intrinsic Bi 2 Te 3 A crystal ingot of composite thermoelectric material is prepared as a raw material.

[0064] First weigh the raw materials so that Cu 2 Te and Bi 2 Te 3 The molar ratio of 6:994, namely Cu 2 The molar content of Te is 0.6%; the raw material is packed into a quartz ampoule and vacuumed to 2.5×10 -4 Pa sealed;

[0065] Then put the quartz ampoule containing the raw materials into the upper furnace of the tube furnace with two temperature zones, and heat to make Bi 2 Te 3 melts and makes Cu 2 Te dissolves in Bi 2 Te 3 In the melt; the temperature of the upper furnace of the tube furnace is 680°C, the temperature of the lower furnace of the tube furnace is 500°C, and the length of the temperature transition zone between the upper furnace and the lower furnace of the tube furnace is 100mm.

[0066] Then let the quartz ampoule drop into the lower furnace of the two-temperature-zone tube furnace at a speed of 50mm / h...

Embodiment 2

[0069] This example uses Cu 2 Te and commercial n-type Bi 2 Te 3 Preparation of composite thermoelectric materials as raw materials.

[0070] First weigh the raw materials so that Cu 2 Te and commercial n-type Bi 2 Te 3 The molar ratio of 6:94, namely Cu 2 The molar content of Te is 6%; the raw material is loaded into a quartz ampoule and vacuumed to 2.8×10 -4 Pa sealed;

[0071] Then put the quartz ampoule containing the raw materials into the upper furnace of the tube furnace with two temperature zones, and heat to make Bi 2 Te 3 melts and makes Cu 2 Te dissolves in Bi 2 Te 3 In the melt; the temperature of the upper furnace of the tube furnace is 650°C, the temperature of the lower furnace of the tube furnace is 350°C, and the length of the temperature transition zone between the upper furnace and the lower furnace of the tube furnace is 200mm.

[0072] Then let the quartz ampoule drop into the lower furnace of the tube furnace with two temperature zones at a sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Seebeck coefficient | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com