Method for comprehensively interpreting infrared detection characteristics of large-size test piece

An infrared detection, large-scale technology, applied in computer parts, image data processing, instruments, etc., can solve the problems of detection integrity degradation, defect omission, and affecting the accuracy of defect quantitative analysis, so as to improve the performance of defect feature characterization and improve The effect of detection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

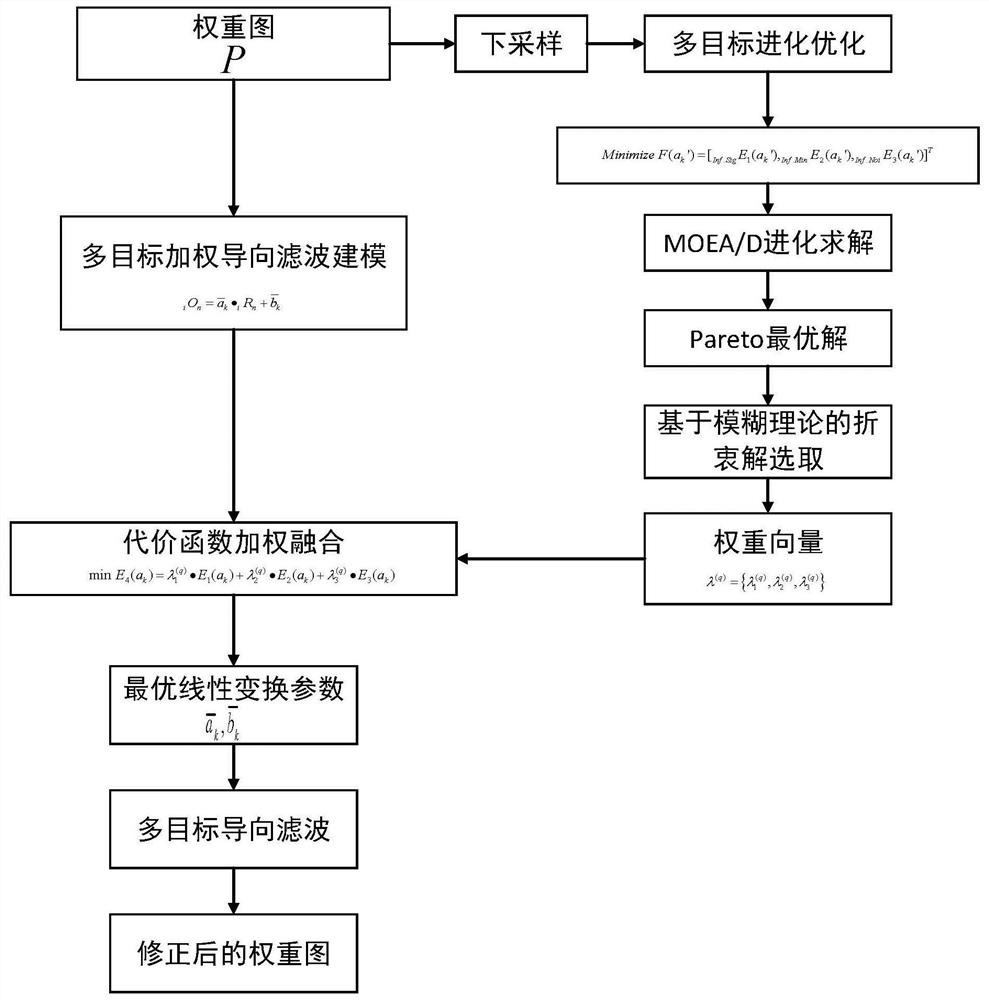

[0245] like Figure 1-3 As shown: a large-size test piece infrared detection feature of the present invention, including the following steps:

[0246] Step 1. Multiple infrared detection of large-size test pieces, obtain a plurality of thermal image sequences of large-sized test pieces, and obtain large size test pieces from multiple heat image sequences using infrared feature extraction and infrared heat image reconstruction algorithm Multiple reconstruction infrared heat images, specific methods include:

[0247] Step S11, a three-dimensional matrix collection of multiple thermal imaging sequences obtained from the infrared thermal imager {s 1 , ..., s i , ..., s |C| } Indicated, where s i A heat image sequence obtained in the infrared thermal imagery in the infrared thermal imagery in the III infrared detection, | C | Represents the total number of hot image sequences; i (m, n, t) represents the Mth row of the TF thermal image in the first thermal image sequence, the temperature...

Embodiment 2

[0357] A step of extracting features using infrared and infrared image reconstruction algorithm to obtain reconstructed infrared thermal image from the infrared image sequence, the specific steps include:

[0358] Step S11, the step S11, the acquisition of the image by the infrared camera into a thermal sequence S, wherein each of the extracted information and the transient thermal response characteristic matrix composed of Fe; wherein, S (i, j, t) represents the image sequence t i-th row of the frame of the thermal image, the pixel values of j-th column, t = 1, ..., T, T is the total number of frames, i = 1, ..., I, I is the number of rows, j = 1, ..., J, J is the total number of columns; of Fe (i, j, f) represents the i-th row feature matrix, the f j th column corresponding to the coordinate position (f = 1, ..., 6) months characteristic information; wherein the first peak amplitude characteristic information heat, i.e., Fe (i, j, 1) = max (S (i, j, :)), S (i, j, :) represents...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com