Logistics freight package damage detection device

A technology for packaging damage and detection devices, which is applied in the directions of measuring devices, optical testing for flaws/defects, and material analysis through optical means. It can solve the problems of high labor intensity and low efficiency of manual detection, and improve accuracy and accuracy. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

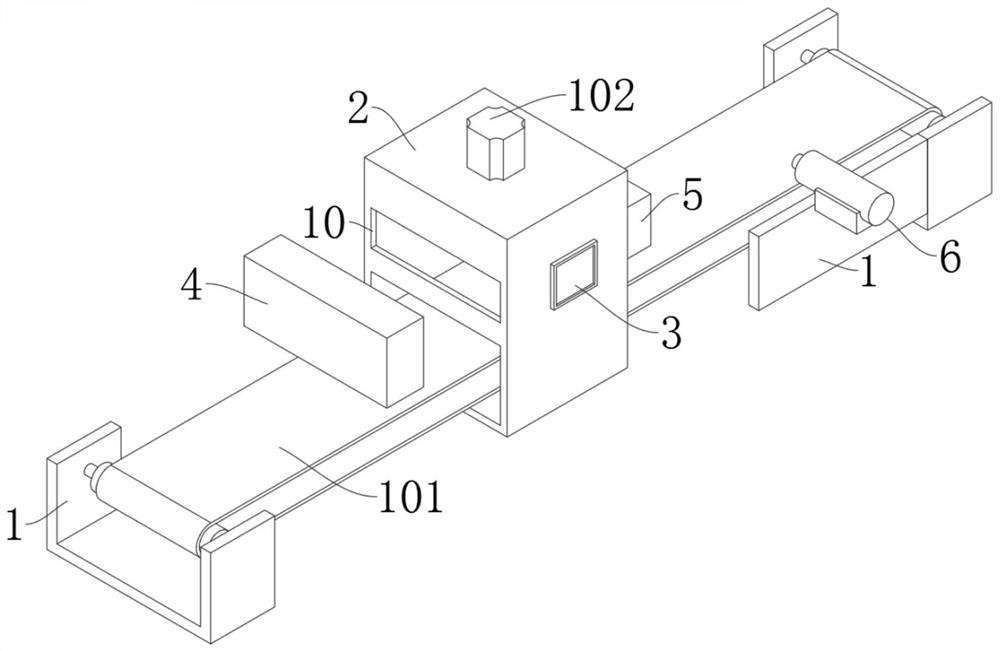

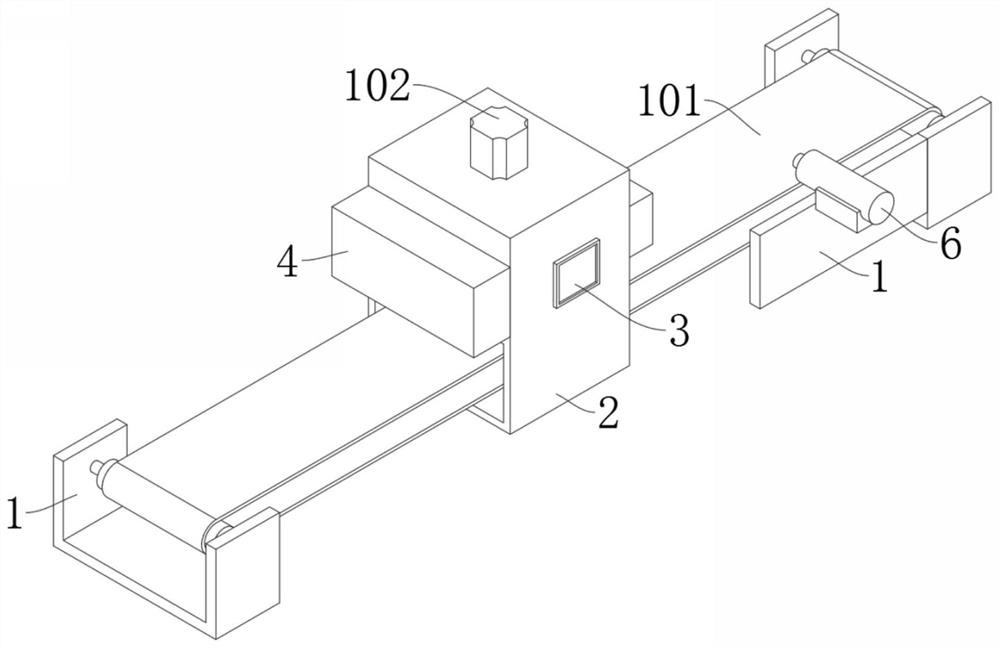

[0032] refer to Figure 1-9 , a logistics freight packaging damage detection device, including a base 1, a conveyor belt 101, the conveyor belt 101 is installed on the base 1, and also includes: a detection box 2 sleeved on the conveyor belt 101, the conveyor belt 101 passes through the detection box 2; The holding frame 103 is connected in the detection box 2 through a rising drive assembly, and is used to drive the holding frame 103 up and down in the detection box 2; the second motor 1031 is fixedly connected to the holding frame 103, and the output terminal of the second motor 1031 The two-way screw rod 1032 is fixedly connected, and the two ends of the two-way screw rod 1032 are respectively threaded with a clamping rod 1033, and one end of the clamping rod 1033 is slidably connected to the clamping frame 103, and the clamping rod 1033 is used for clamping the package; the third motor 104, fixedly connected to the ends of one group of clamping rods 1033; two groups of rot...

Embodiment 2

[0039] refer to Figure 7 , a damage detection device for logistics and freight packaging, which is basically the same as that of Embodiment 1, furthermore: one end of the rotating column 1041 is fixedly connected with a clamping plate 1042;

[0040] The package can be more stably clamped by the clamping plate 1042 to prevent the package from falling after being clamped.

Embodiment 3

[0042] refer to Figure 7 , a damage detection device for logistics and freight packaging, which is basically the same as that of Embodiment 2, furthermore: the clamping plate 1042 is fixedly connected with an anti-skid pad 1043;

[0043] The anti-slip pad 1043 can increase the friction between the clamping plate 1042 and the package, preventing the package from slipping from between the clamping plates 1042 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com