Novel high-temperature-resistant nano-composite zirconium cross-linking agent as well as preparation method and application thereof

A nano-composite and cross-linking agent technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor shear resistance and high production costs, and achieve good temperature resistance and strong shear resistance , The effect of facilitating the promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

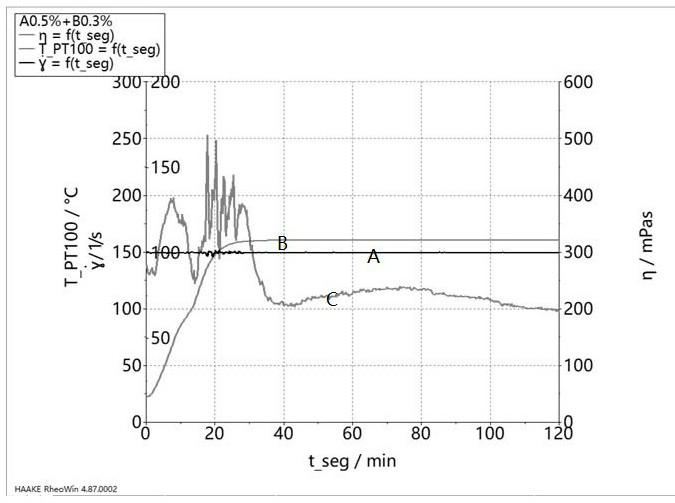

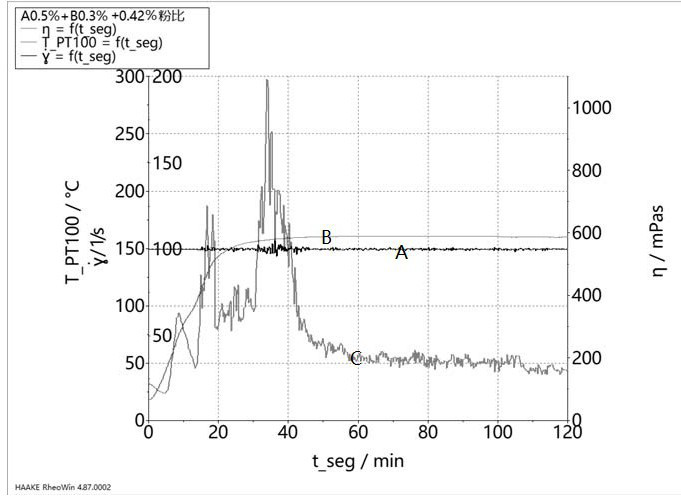

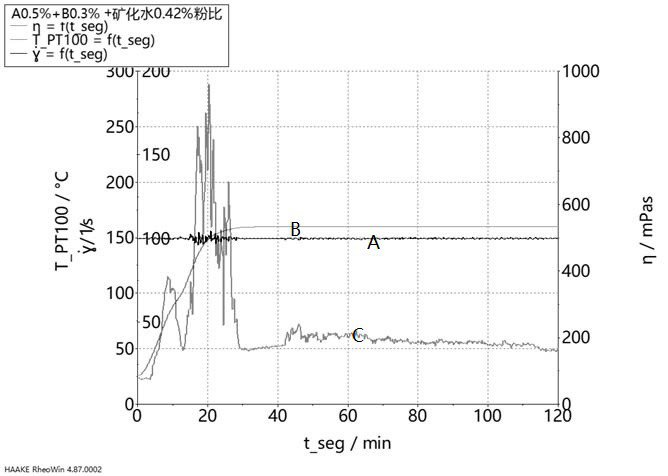

Image

Examples

preparation example Construction

[0033] The present invention also provides a preparation method of a novel high-temperature-resistant nanocomposite zirconium crosslinking agent, comprising the following steps:

[0034] Step (1) Preparation of organic zirconium crosslinking agent: Weigh each raw material according to the weight ratio, slowly add the inorganic zirconium salt into the ethylene glycol solution, stir while adding, until the inorganic zirconium salt is completely dissolved, and then mix the reaction system Heating to 40°C, reacting in a closed environment for 1 hour, then raising the temperature to 50°C, then adding polyols in proportion by weight, reacting for 1 hour, and finally adding organic acid, reacting for 2-3 hours; cooling the above reaction system to At room temperature, a light yellow liquid is obtained, which is an organic zirconium crosslinking agent;

[0035] Step (2) Preparation of the nanocomposite zirconium crosslinking agent: adding the nanoparticle material to the dispersant, t...

Embodiment 1

[0042] A new type of high temperature resistant nanocomposite zirconium crosslinking agent, which is composed of the following raw materials in parts by weight: 45 parts of ethylene glycol, 7 parts of zirconium oxychloride, 15 parts of glycerol, 23 parts of lactic acid, 0.1 part of nano silicon dioxide, 10 parts of absolute ethanol.

[0043] The preparation method of this linking agent comprises the following steps:

[0044] Step (1) Preparation of the organic zirconium crosslinking agent: Weigh each raw material according to the weight ratio, slowly add zirconium oxychloride to the ethylene glycol solution, stir while adding, until the zirconium oxychloride is completely dissolved, and then Heating the reaction system to 40°C, reacting in a closed environment for 1 hour, then raising the temperature to 50°C, then adding glycerol in proportion by weight, reacting for 1 hour, and finally adding lactic acid, reacting for 2-3 hours; the above reaction system Cool to room tempera...

Embodiment 2

[0050] A novel high-temperature-resistant nanocomposite zirconium crosslinking agent is composed of the following raw materials in parts by weight: 50 parts of ethylene glycol, 10 parts of zirconium oxychloride and zirconium tetrachloride in total, glycerol, sorbitol and mannitol in total 18 parts, a total of 26 parts of lactic acid, citric acid, and acetic acid, 0.2 parts of nano-calcium carbonate, and 20 parts of anhydrous methanol.

[0051] The preparation method of the cross-linking agent and the steps of using the cross-linking agent to prepare the acidic cross-linked fracturing fluid are the same as those in Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com