Nano core-shell combustion catalyst and preparation method thereof

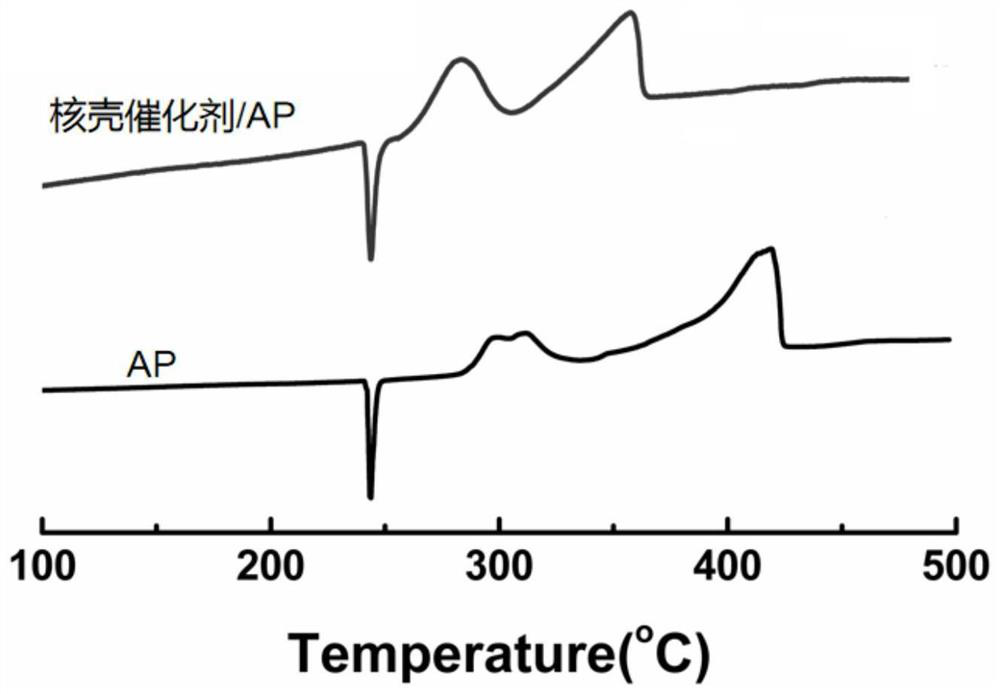

A combustion catalyst, nano-core-shell technology, applied in the direction of offensive equipment, non-explosive/non-thermal agent components, explosives, etc., can solve the problems of affecting catalytic performance, easy agglomeration of nanoparticles, and reduction of specific surface, so as to achieve high catalytic combustion efficiency , avoid agglomeration, high activity and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

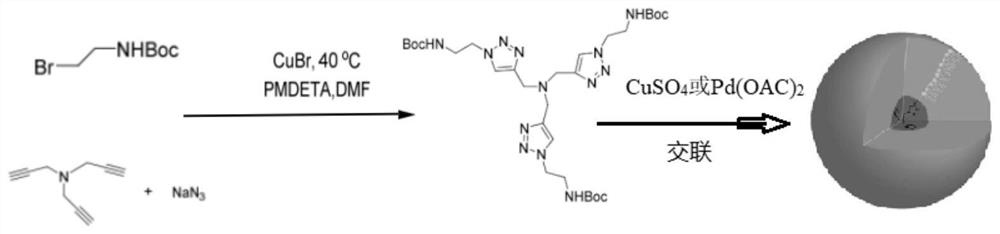

[0032] A preparation method of a nano-core-shell combustion catalyst, comprising the following steps:

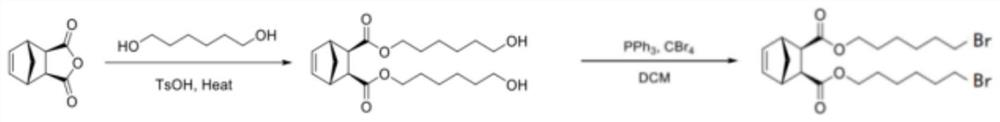

[0033] Step 1. Disperse 0.5g of cis-5-norbornene-exo-2,3-dicarboxylic anhydride into 20mL of hexanediol, heat to 40°C, and stir magnetically at 300r / min until it is completely dissolved; then add 60mg p-toluenesulfonic acid, vacuum reaction for 30min, after the reaction was completed, the solution was cooled to room temperature, diluted and washed with 10mL ethyl acetate and 10mL aqueous sodium bicarbonate solution (concentration 5wt%), collected the organic layer, and evaporated under reduced pressure to obtain the diol monomer sample;

[0034] Step 2: Dissolve 0.5 g of the diol monomer sample in 10 mL of dichloromethane to form a solution, add 50 mg of carbon tetrabromide to cool in an ice-water bath at 0°C, add 4 mL of triphenylphosphine dropwise, and after the dropwise addition, remove the Take it out from the ice-water bath and heat to 30°C and stir. The stirring adopt...

Embodiment 2

[0044] A preparation method of a nano-core-shell combustion catalyst, comprising the following steps:

[0045] Step 1. Disperse 0.5g of cis-5-norbornene-exo-2,3-dicarboxylic anhydride into 20mL of hexanediol, heat to 40°C, and stir magnetically at 350r / min until it is completely dissolved; then add 0.06 g p-toluenesulfonic acid, vacuum reaction 45min, after the completion of the reaction, the solution was cooled to room temperature, diluted with 10mL ethyl acetate and 10mL aqueous sodium bicarbonate (concentration 5wt%), washed, the organic layer was collected, evaporated under reduced pressure to obtain diol mono Body samples;

[0046] Step 2: Dissolve 0.5g of the diol monomer sample in 10mL of dichloromethane to form a solution, add 0.04g of carbon tetrabromide to cool in an ice-water bath at 0°C, add 4mL of triphenylphosphine dropwise, and after the dropwise addition, Take it out from the ice-water bath, heat it to 30°C and stir, use magnetic stirring for stirring, remove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com