A kind of mullite-based ceramic material and preparation method thereof

A ceramic material, mullite-based technology, applied in the field of refractory ceramic materials, can solve the problems of difficult dispersion of whiskers, poor dispersion uniformity, and high production difficulty, and achieve the goals of reducing calcination time, high whisker content, and reducing sintering time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

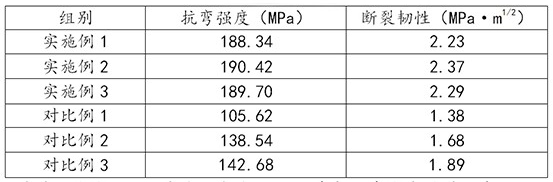

Examples

Embodiment 1

[0031] The preparation of mullite seed crystal comprises the following steps:

[0032] According to the ratio of ethyl orthosilicate, aluminum nitrate and ethanol in the ratio of 3mol:2mol:1L, mix 0.3mol ethyl orthosilicate and 0.2mol aluminum nitrate and add them to 100mL of ethanol, then add dropwise 1mol / L hydrochloric acid solution to a pH of 2, reacted at 60°C for 3 hours to obtain a silica-alumina sol, added 4 mol / L ammonia water to the silica-alumina sol dropwise until the pH was 6, and reacted at 60°C for 10 hours to obtain a silica-alumina sol Aluminum gel, drying the silica-alumina gel at 70°C, calcining at 1000°C, and cooling to obtain highly active mullite seeds with a diameter of 52-55nm and a length of 1.5-1.7μm.

[0033] The preparation of phosphate binder comprises the following steps:

[0034] Step A1, Al(OH) 3 Added to H with a mass fraction of 60% 3 PO 4 In solution, Al(OH) 3 with H 3 PO 4 The molar ratio of the solute in the solution is 5:4 to obtain...

Embodiment 2

[0042] The preparation of mullite seed crystal comprises the following steps:

[0043] According to the ratio of ethyl orthosilicate, aluminum nitrate and ethanol in the ratio of 3mol:2mol:1L, mix 0.3mol ethyl orthosilicate and 0.2mol aluminum nitrate and add them to 100mL of ethanol, then add dropwise 1mol / L hydrochloric acid solution to a pH of 2, reacted at 60°C for 4 hours to obtain a silica-alumina sol, added 4 mol / L ammonia water to the silica-alumina sol dropwise until the pH was 6, and reacted at 60°C for 11 hours to obtain a silica-alumina sol Aluminum gel, drying the silica-alumina gel at 80°C, calcining at 1200°C, and cooling to prepare mullite seed crystals with a diameter of 58-63nm and a length of 1.6-1.8μm.

[0044] The preparation of phosphate binder comprises the following steps:

[0045] Step A1, Al(OH) 3 Added to H with a mass fraction of 60% 3 PO 4 In solution, Al(OH) 3 with H 3 PO 4 The molar ratio of the solute in the solution is 5:4 to obtain a mi...

Embodiment 3

[0053] The preparation of mullite seed crystal comprises the following steps:

[0054] According to the ratio of ethyl orthosilicate, aluminum nitrate and ethanol in the ratio of 3mol:2mol:1L, mix 0.3mol ethyl orthosilicate and 0.2mol aluminum nitrate and add them to 100mL of ethanol, then add dropwise 1mol / L hydrochloric acid solution to pH 2, react at 60°C for 5 hours to obtain silica-alumina sol, add 4 mol / L ammonia water to the silica-alumina sol dropwise to pH 6, and react at 60°C for 12 hours to obtain silica Aluminum gel, drying the silica-alumina gel at 90°C, calcining at 1300°C, and cooling to prepare mullite seed crystals with a diameter of 62-69nm and a length of 1.7-2.0μm.

[0055] The preparation of phosphate binder comprises the following steps:

[0056] Step A1, Al(OH) 3 Added to H with a mass fraction of 60% 3 PO 4 In solution, Al(OH) 3 with H 3 PO 4 The molar ratio of the solute in the solution is 5:4 to obtain a mixed solution, which is heated to 85°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com