Organic fertilizer granulation equipment capable of avoiding generation of chippings and caking

A granulation equipment and organic fertilizer technology, applied in lighting and heating equipment, dryers, manure drying, etc., can solve the problems of easy pollution of the environment, waste of water vapor, and organic fertilizer particles sticking together to ensure uniformity The effect of ensuring firmness, guaranteeing compactness and guaranteeing integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

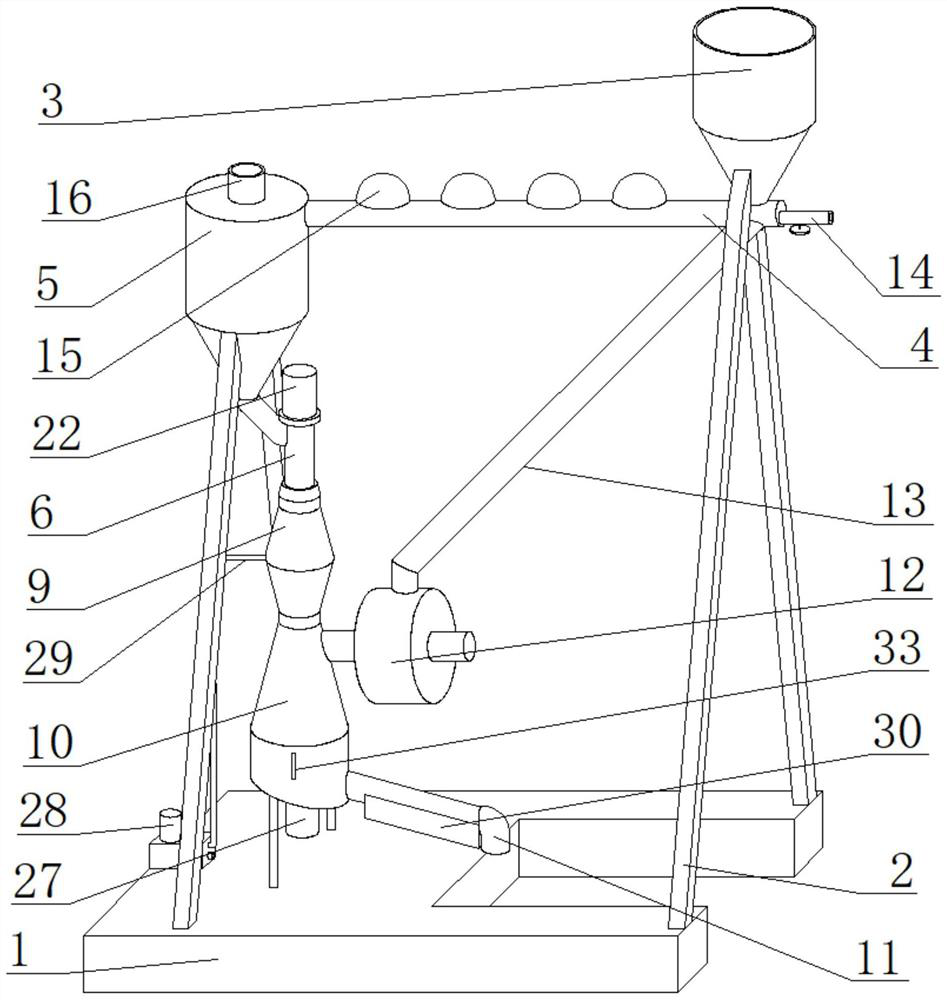

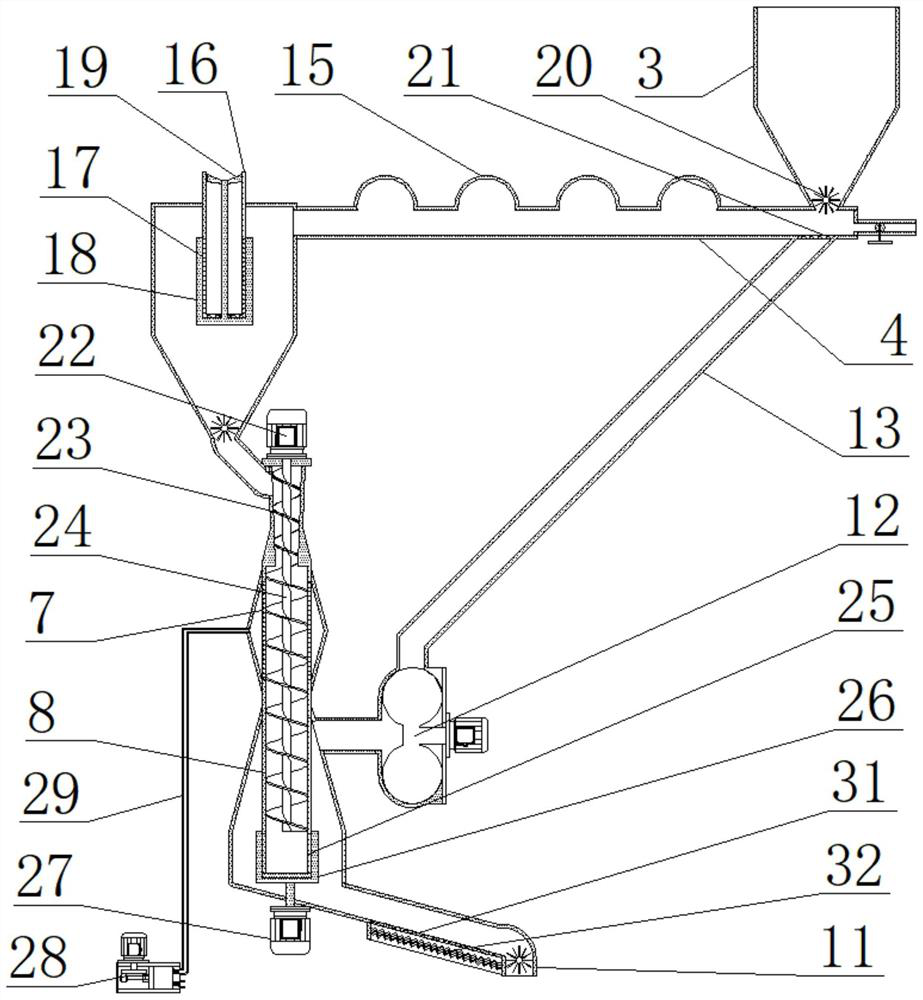

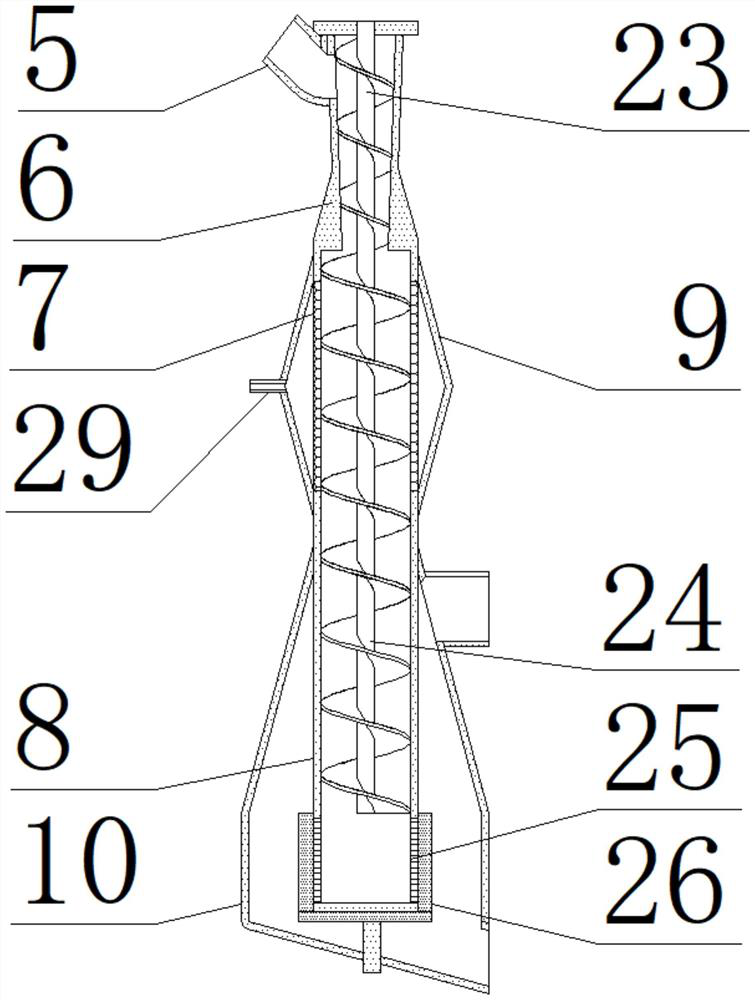

[0027] As a preferred embodiment of the present invention, the switch 33 is connected with the first motor 22 , the second motor 27 , the vacuum pump 28 , the feeding valve 20 , the fan 12 and the heating wire 32 through wires.

[0028] As a preferred embodiment of the present invention, the one-way valve 21 is installed at the bottom of the horizontal pipe 4, a valve is installed on the air pipe 14, and the wind chamber 15 is evenly distributed on the top of the horizontal pipe 4, and the inside of the hopper 3 The organic fertilizer falls into the horizontal pipe 4 through the feeding valve 20, and the fan 12 works to generate air flow, and the organic fertilizer debris, water vapor and peculiar smell in the outer cylinder 10 are passed through the air pipe 13 and then through the one-way valve 21 by using the air flow. Into the horizontal tube 4, use the airflow to blow the organic fertilizer to make it flow in the horizontal tube 4 to the cyclone 5, when flowing through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com