High-sealing-performance vaccine glass bottle

A high-sealing, glass bottle technology, applied in the field of high-sealing vaccine glass bottles, can solve problems such as difficulty in ensuring that the bottle stopper is detached, difficult to meet the use environment, and unable to ensure complete sealing of vaccines from contamination, etc. Improved sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

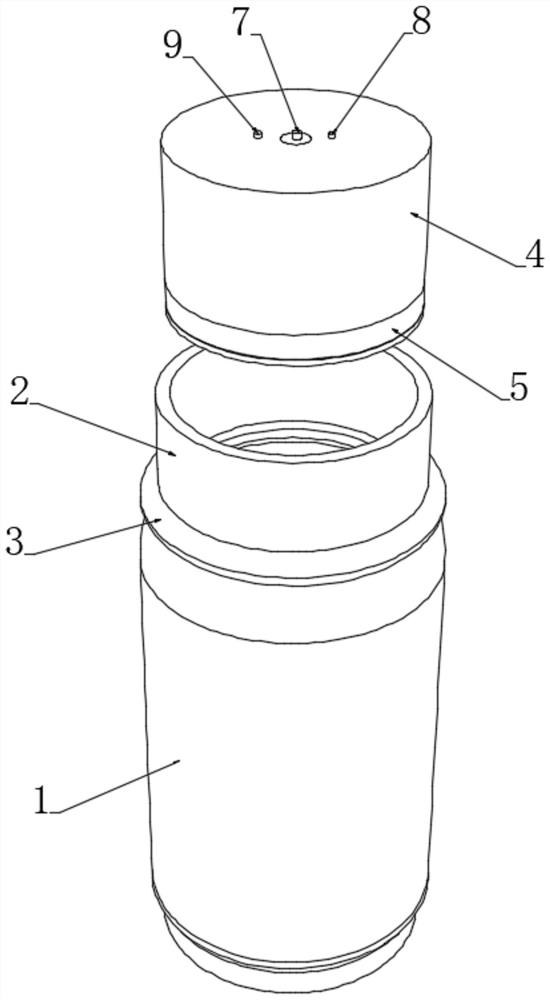

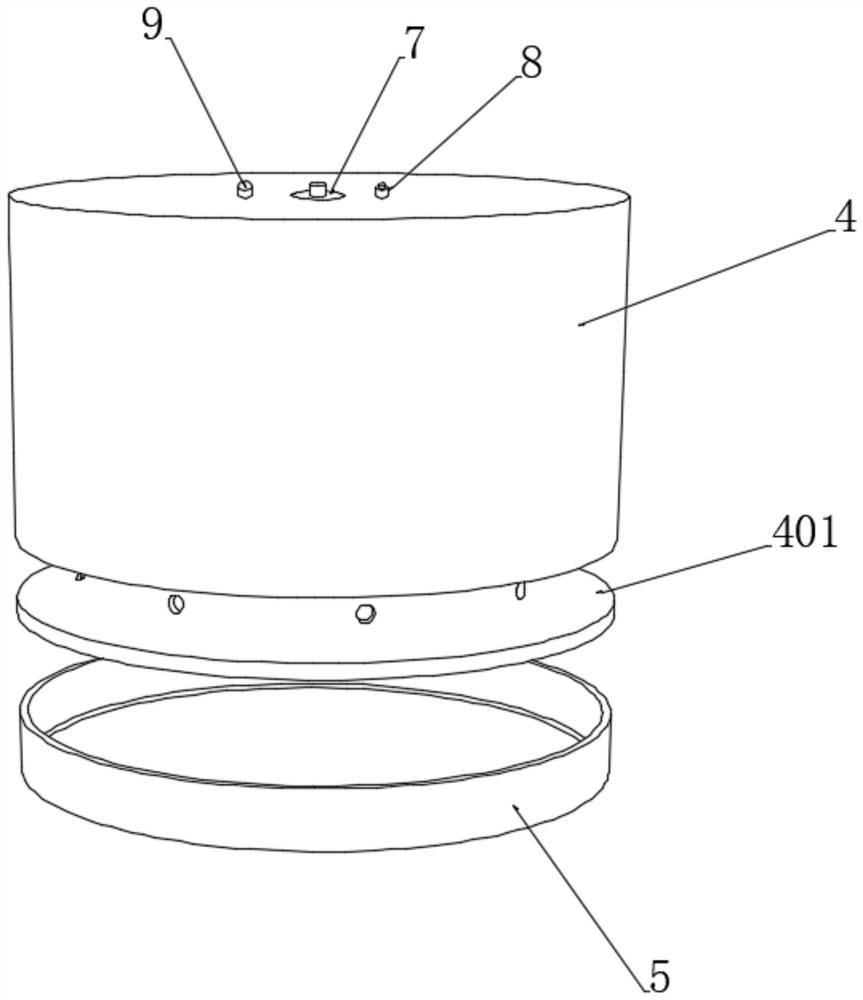

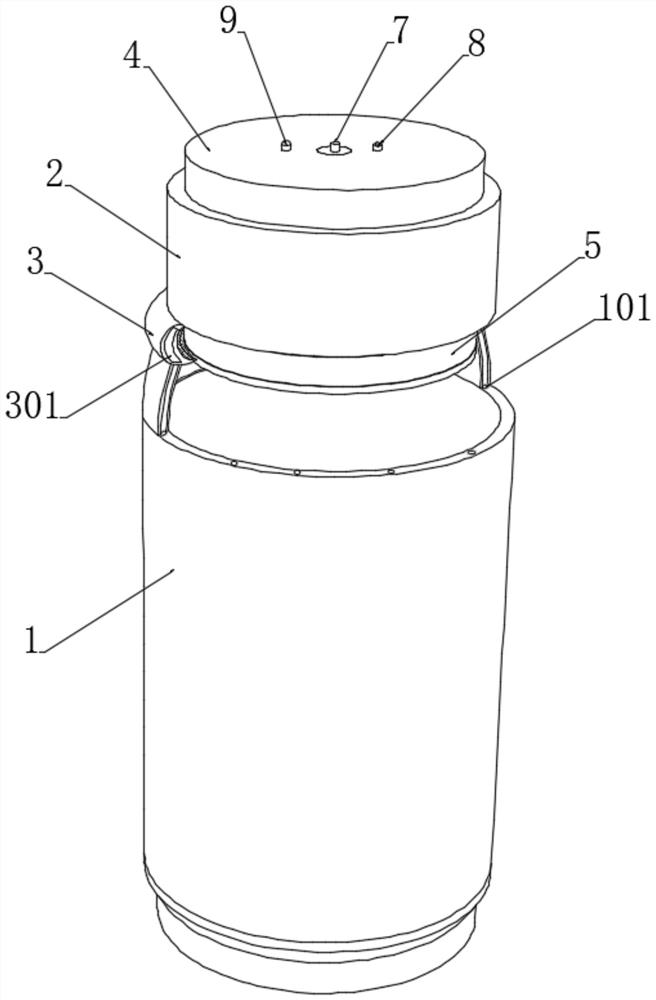

[0041] see Figure 1-5, a high-tightness vaccine glass bottle, including a bottle body 1 with a bottle mouth 2, a fitting part 3 is provided between the bottle body 1 and the bottle mouth 2, a bottle stopper 4 is sealed and connected at the bottle mouth 2, the bottle The outer end wall near the lower end of the plug 4 is provided with an air guide cavity 401 corresponding to the position of the fitting part 3, and an elastic sealing bag 5 is arranged on the outside of the air guiding cavity 401. The elastic sealing bag 5 is made of elastic heat-conducting material, and is elastically sealed. The bladder 5 has an inner and outer double-layer structure, and the air guide cavity 401 is provided with a magnetic extruded part, the inner wall of the fitting part 3 is provided with an arc-shaped cavity, the inner wall of the arc-shaped cavity is covered with a gasket 302, and the inner wall of the fitting part 3 is embedded with a The magnetic layer 301 is magnetically arranged with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com