Cleanliness control system of clean room

A control system and clean room technology, which is applied in the field of clean room cleanliness control system, can solve problems such as inability to monitor and control the cleanliness of the clean room, and achieve the effect of convenient maintenance and guaranteed production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

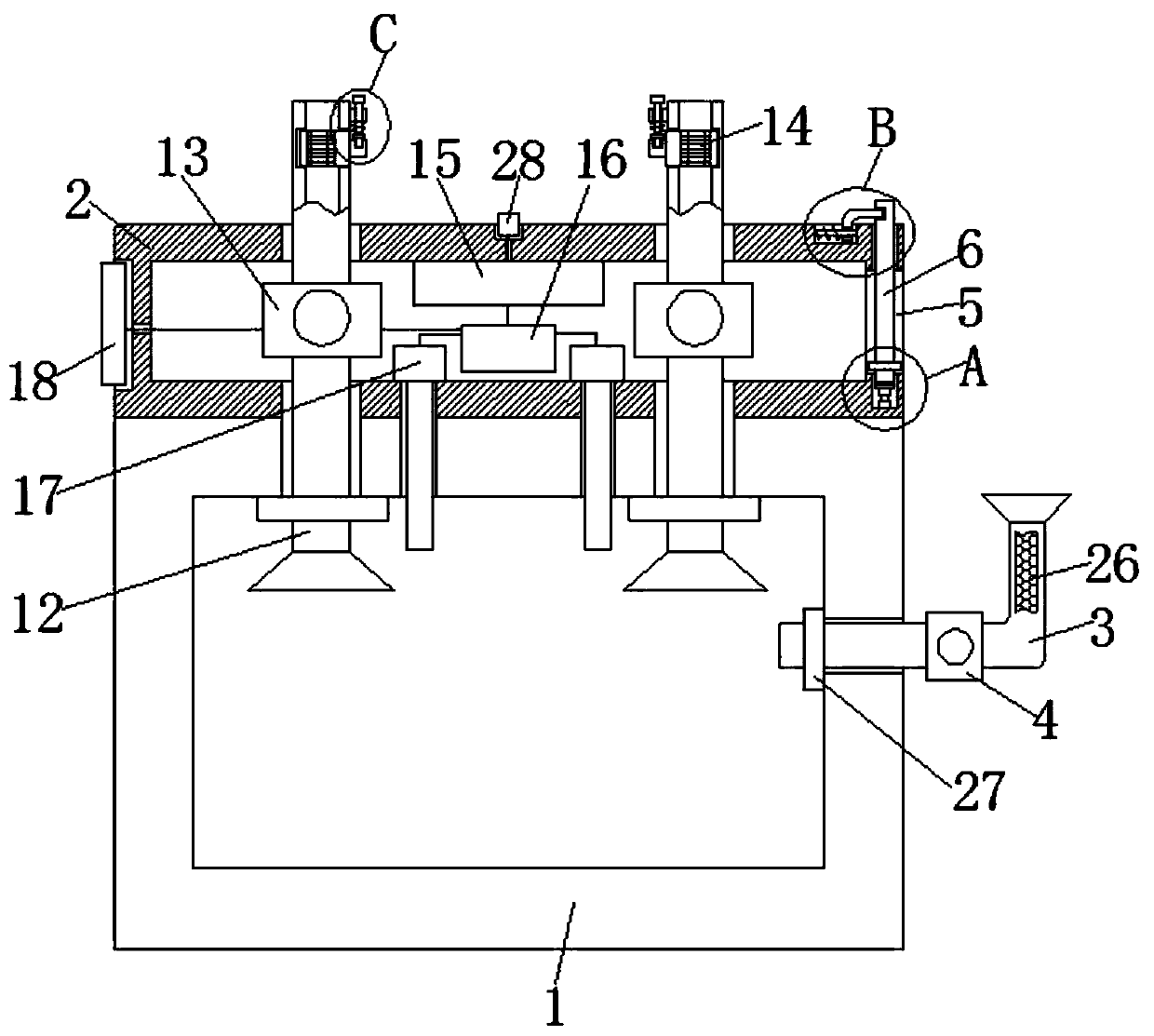

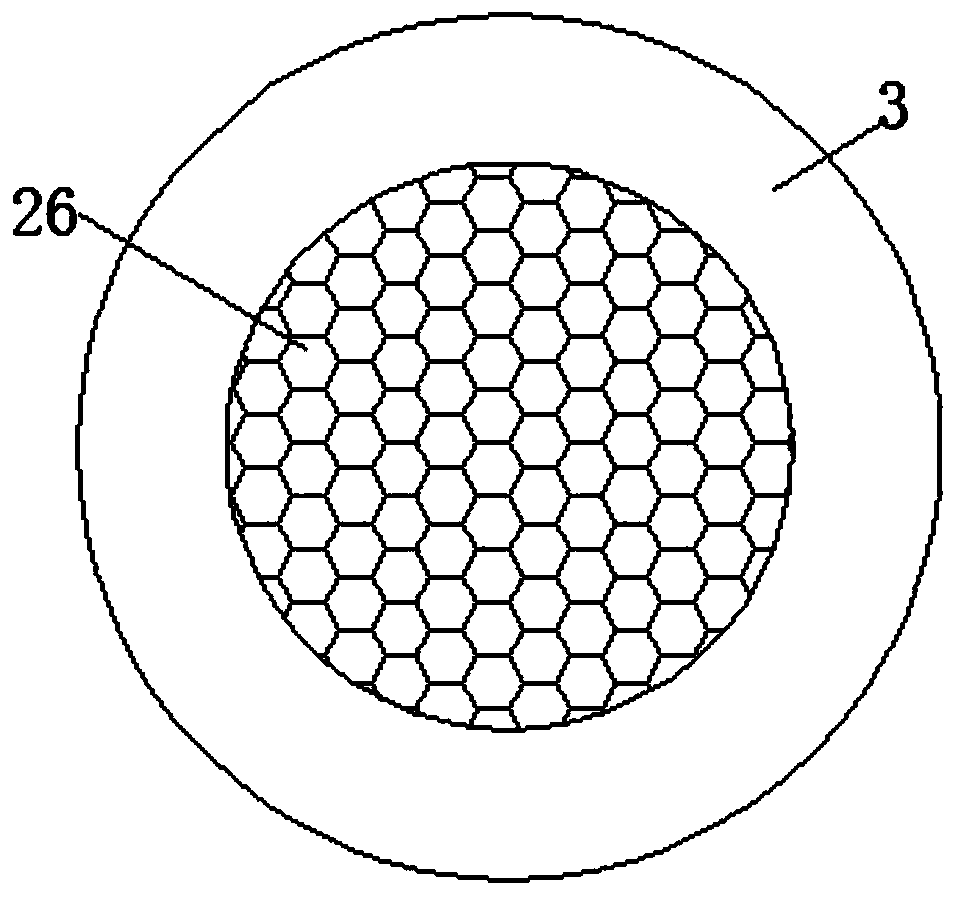

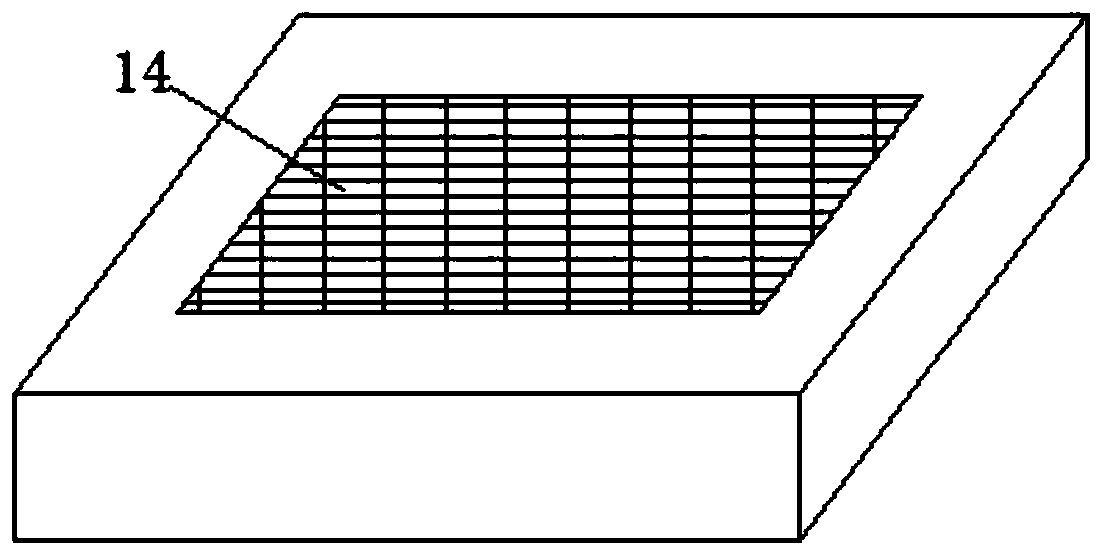

[0036] refer to Figure 1-6 , the cleanliness control system of the clean room, including the control box 2 arranged on the top of the clean room body 1, used to set the control elements, the top of the inner wall of the clean room body 1 side is fixedly inserted with an air intake pipe 3, used to introduce air , the intake pipe 3 is threadedly connected with a suction fan 4 for sucking external air into the clean room body 1;

[0037] In this embodiment, the inner wall of the control box 2 near the intake pipe 3 is provided with a mounting port 5 for convenient installation of electronic components, and a baffle plate 6 is slidably inserted in the mounting port 5 to protect the electronic components. The bottom of 6 is fixedly sleeved with the limit sleeve 7 to prevent the baffle plate 6 from falling off from the installation port 5. One end of the baffle plate 6 penetrates the inner wall of the installation port 5 and extends upwards. The outer wall of the control box 2 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com