Device and method for testing oil stirring loss of rolling bearing

A testing device and rolling bearing technology, which is applied in the direction of mechanical bearing testing, etc., can solve the problems of inability to extract, narrow application range, etc., and achieve the effect of simple structure, guaranteed accuracy, and improved detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of rolling bearing churning loss test method based on the above-mentioned device, comprises the following steps:

[0041] S1: Install and debug each test device, close the bypass valve for through-lubrication in the test box, and open the bypass valve for oil injection lubrication, so as to switch the lubrication mode to oil injection lubrication;

[0042] S2: Start the constant temperature and constant pressure oil supply system to adjust the lubricating oil in the oil tank to the temperature to be tested;

[0043] S3: Start the power pump to send lubricating oil into the test box along the pipeline to pre-lubricate the bearings to be tested; at the same time, use the pressure measurement and controller to ensure that the pressure at the nozzle of each bearing to be tested is the same;

[0044] S4: Start the motor to make the main shaft reach the speed to be tested, and wait for the data returned by the speed torque sensor to show that the motor speed is stable;...

Embodiment 2

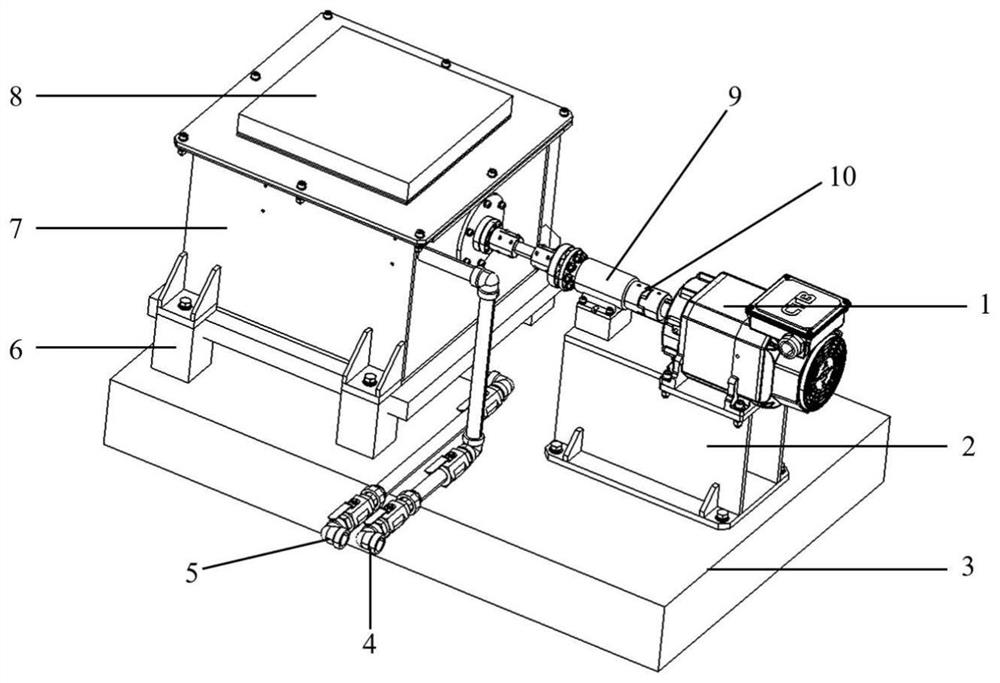

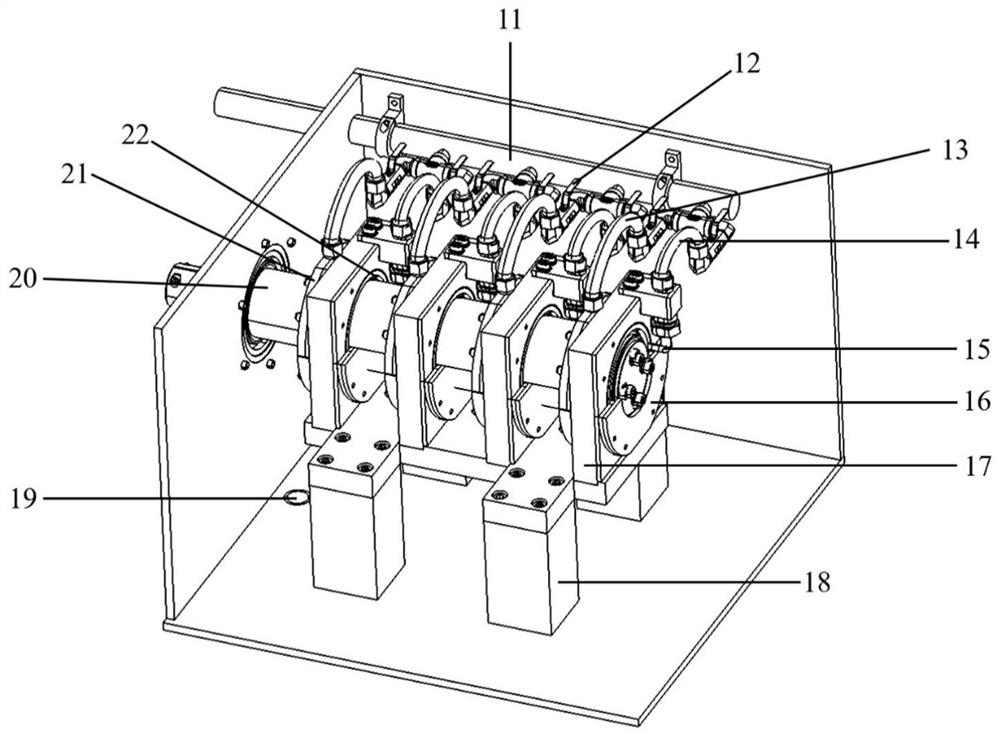

[0049] In this example, the oil churning loss of the rolling bearing in the through lubrication mode is tested, and the main test devices include figure 1 , figure 2 shown.

[0050] Specific steps:

[0051] S1: Install and debug each test device, close the bypass valve for oil injection lubrication in the test box, and open the bypass valve for through lubrication, so as to switch the lubrication mode to through lubrication;

[0052] S2: Start the constant temperature and constant pressure oil supply system to adjust the lubricating oil in the oil tank to the temperature to be tested;

[0053] S3: Start the power pump to inject lubricating oil into the test box along the pipeline to pre-lubricate the bearings to be tested; at the same time, the measurement and control system ensures that the flow into each bearing to be tested is the same;

[0054] S4: Start the motor to make the main shaft reach the speed to be tested. After the data transmitted by the speed torque sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com