Chiral nanorod film with circular polarization fluorescence

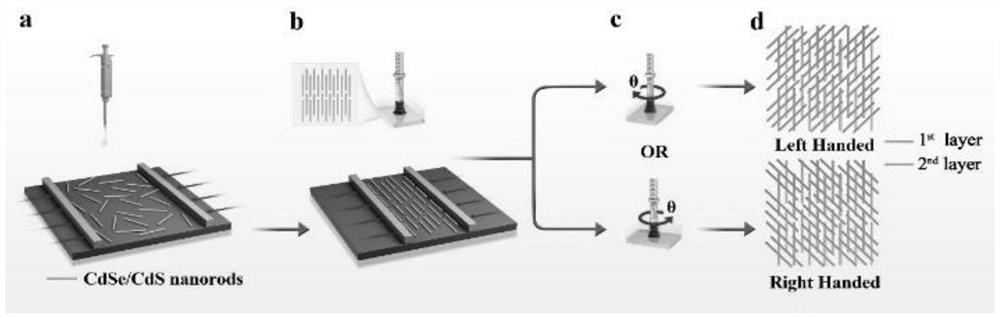

A nanorod and circular polarization technology, applied in the fields of nanomaterials and optics, can solve the problems of inaccurate prediction of CPL activity of chiral luminophores, cumbersome synthesis process, etc., and achieve the effects of easy control of structure and good film formation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

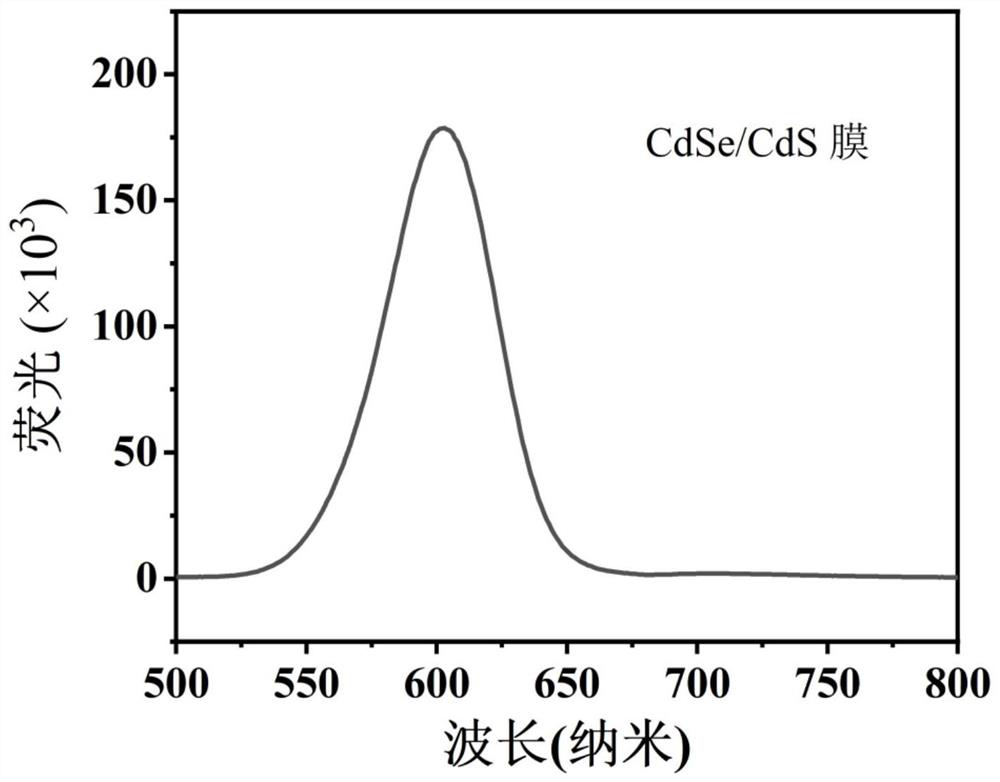

[0036] The preparation of embodiment 1CdSe / CdS nanorod film

[0037] In this example, a CdSe / CdS nanorod film was prepared using a film pulling machine, and the specific preparation steps are as follows:

[0038] (1) Disperse the CdSe / CdS nanorods in n-hexane to obtain a 3 mg / mL dispersion, and add 600 microliters of the dispersion dropwise to the surface of ethylene glycol in the film pulling machine tank;

[0039] (2) Compress the sliding barrier from both sides to the middle at a speed of 1 mm / s until the surface pressure is 30 mN / m, forming a nanorod film on the surface of the water phase;

[0040] (3) The nanorod film was horizontally transferred to a clean quartz plate, and dried at 65° C. to obtain a CdSe / CdS nanorod film.

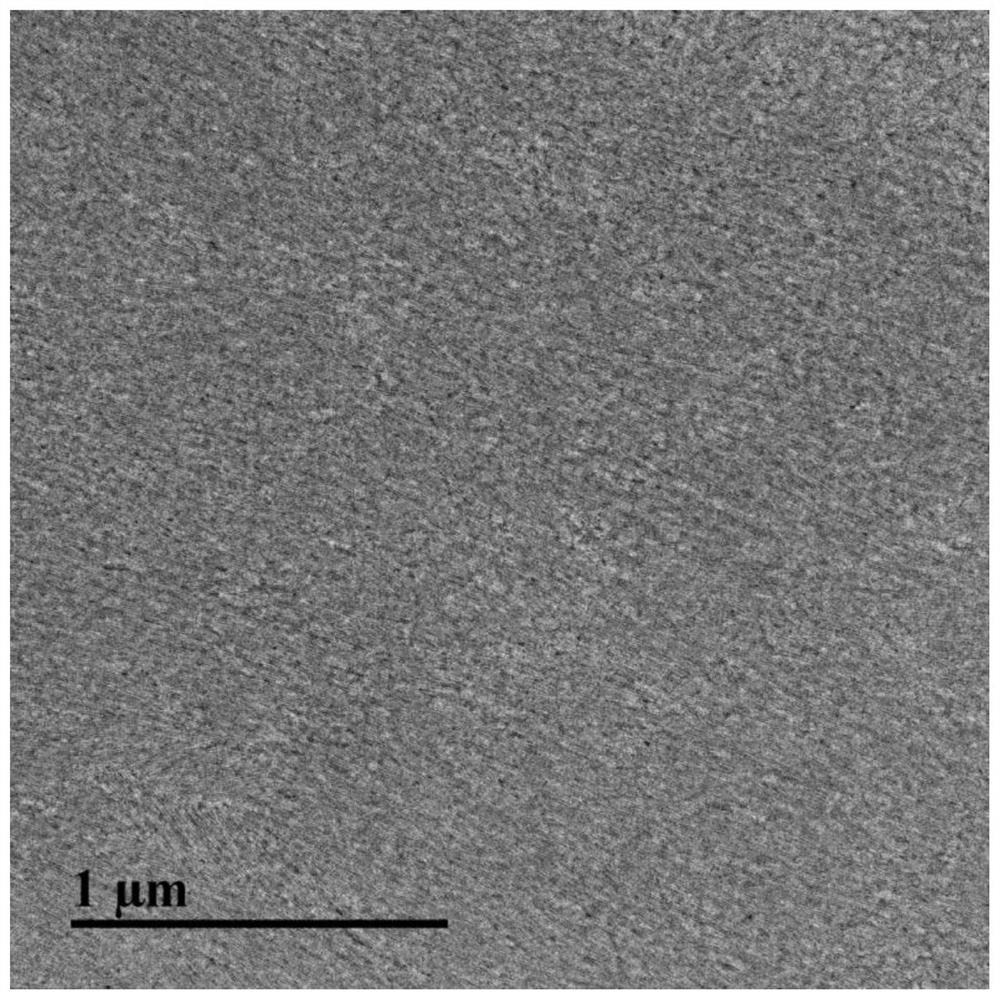

[0041] The prepared CdSe / CdS nanorod film was characterized by transmission electron microscopy, as shown in figure 2 As shown, the prepared CdSe / CdS nanorod film has a uniform, smooth surface and no defects visible to the naked eye.

Embodiment 2

[0042] Example 2 Preparation of RH45°-1+1 chiral CdSe / CdS nanorod film

[0043] Consistent with the operation of Example 1, prepare a layer of CdSe / CdS nanorod film on the quartz plate, repeat the steps (1) and (2) of Example 1 to form a nanorod film in the aqueous phase, and rotate the quartz plate counterclockwise for 45 °, the nanorod film was transferred to the film-coated surface of the quartz plate, and dried at 65°C to obtain a RH45°-1+1 chiral CdSe / CdS nanorod film.

Embodiment 3

[0044] Example 3 Preparation of LH45°-1+1 chiral CdSe / CdS nanorod film

[0045] Consistent with the operation of Example 1, prepare a layer of CdSe / CdS nanorod film on the quartz plate, repeat the steps (1) and (2) of Example 1 to form a nanorod film in the aqueous phase, and rotate the quartz plate clockwise for 45 °, the nanorod film was transferred to the film-coated surface of the quartz plate, and dried at 65°C to obtain the LH45°-1+1 chiral CdSe / CdS nanorod film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com