Preparation method of foam microporous material

A microporous material and foam technology, which is applied in the field of foam microporous material preparation, can solve the problems of easy collapse of cells, low porosity, and poor stability, and achieve fine and uniform pores, regular cell structure, and prevent foam from collapsing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

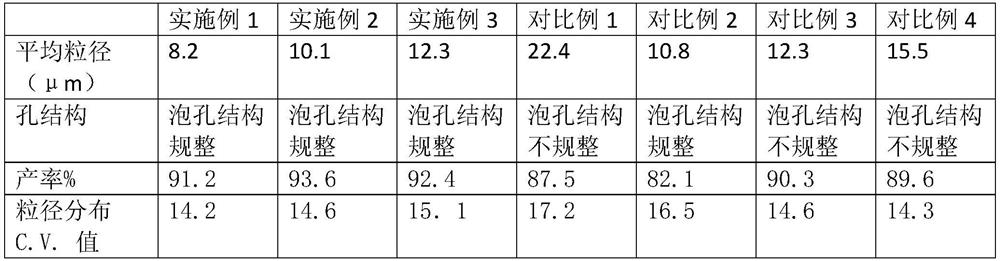

Examples

Embodiment 1

[0021] A kind of preparation method of foam microporous material, wherein: comprise the following steps:

[0022] S1. 2 parts of surfactants, 1 part of foam stabilizer, 1 part of single-walled carbon nanotubes and 3 parts of graphene oxide are added to 5 parts of deionized water to prepare a homogeneous aqueous solution as the water phase; 20 parts of chemical Monomer, 4 parts of initiator and 40 parts of N-methylpyrrolidone are prepared into a homogeneous oil solution as the oil phase; the water phase and the oil phase are quickly mixed and then prepared by homogeneous emulsification, stirring or ultrasonic method to obtain W / O type Pre-emulsion; Surfactant is lauroyl glutamic acid, cetearyl glucoside, mass ratio is 1:1; Foam stabilizer includes 20wt% fatty acid methyl ester ethoxylate sulfonate, 35wt% polyether modification Silicone oil and 45wt% polyoxyethylene-polyoxypropylene copolymer; chemical monomer is styrene; initiator includes 15wt% tert-butyl peroxybenzoate, 30wt%...

Embodiment 2

[0026] A method for preparing a foam microcellular material, characterized in that: comprising the following steps:

[0027] S1. Add 5 parts of surfactants, 2 parts of foam stabilizers, 5 parts of single-walled carbon nanotubes and 5 parts of graphene oxide into the water phase and add to 7 parts of deionized water to prepare a homogeneous aqueous solution as the water phase ; 25 parts of chemical monomers, 5 parts of initiator and 50 parts of N-methylpyrrolidone are prepared into a homogeneous oil solution as the oil phase; the water phase and the oil phase are quickly mixed and prepared by homogeneous emulsification, stirring or ultrasonic method Obtain W / O type pre-emulsion; Surfactant is cocoyl diethanolamide; Foam stabilizer comprises 22wt% fatty acid methyl ester ethoxylate sulfonate, 37wt% polyether modified silicone oil and 41wt% polyoxyethylene- Polyoxypropylene copolymer; chemical monomer is ethyl styrene; initiators include 18 wt% tert-butyl peroxybenzoate, 32 wt% d...

Embodiment 3

[0031] A kind of preparation method of foam microporous material, wherein: comprise the following steps:

[0032] S1. 6 parts of surfactants, 3 parts of foam stabilizers, 20 parts of single-walled carbon nanotubes and 6 parts of graphene oxide are added to 10 parts of deionized water to prepare a homogeneous aqueous solution as the water phase; 30 parts of chemical Monomer, 8 parts of initiator and 60 parts of N-methylpyrrolidone are prepared into a homogeneous oil solution as the oil phase; the water phase and the oil phase are quickly mixed and then prepared by homogeneous emulsification, stirring or ultrasonic method to obtain W / O type Pre-emulsion; surfactant is cetearyl glucoside and cocoyl diethanolamide, mass ratio is 1:1, foam stabilizer includes 25wt% fatty acid methyl ester ethoxylate sulfonate, 40wt% polyether Modified silicone oil and 35wt% polyoxyethylene-polyoxypropylene copolymer; the chemical monomer is isooctyl acrylate, and the initiator includes: 20wt% tert-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com