AGV carrying, receiving and dispatching small-area operation method

An operation method, small area technology, applied in transportation and packaging, loading/unloading, conveyors, etc., can solve the problems of weakening the advantages of AGV, large occupied area of AGV receipt and delivery, limited site area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0038] It can be known from common technical knowledge that the present invention can be realized through other embodiments without departing from its spirit or essential features. Accordingly, the above-disclosed embodiments are, in all respects, illustrative and not exclusive. All changes within the scope of the present invention or within the scope equivalent to the present invention are embraced by the present invention.

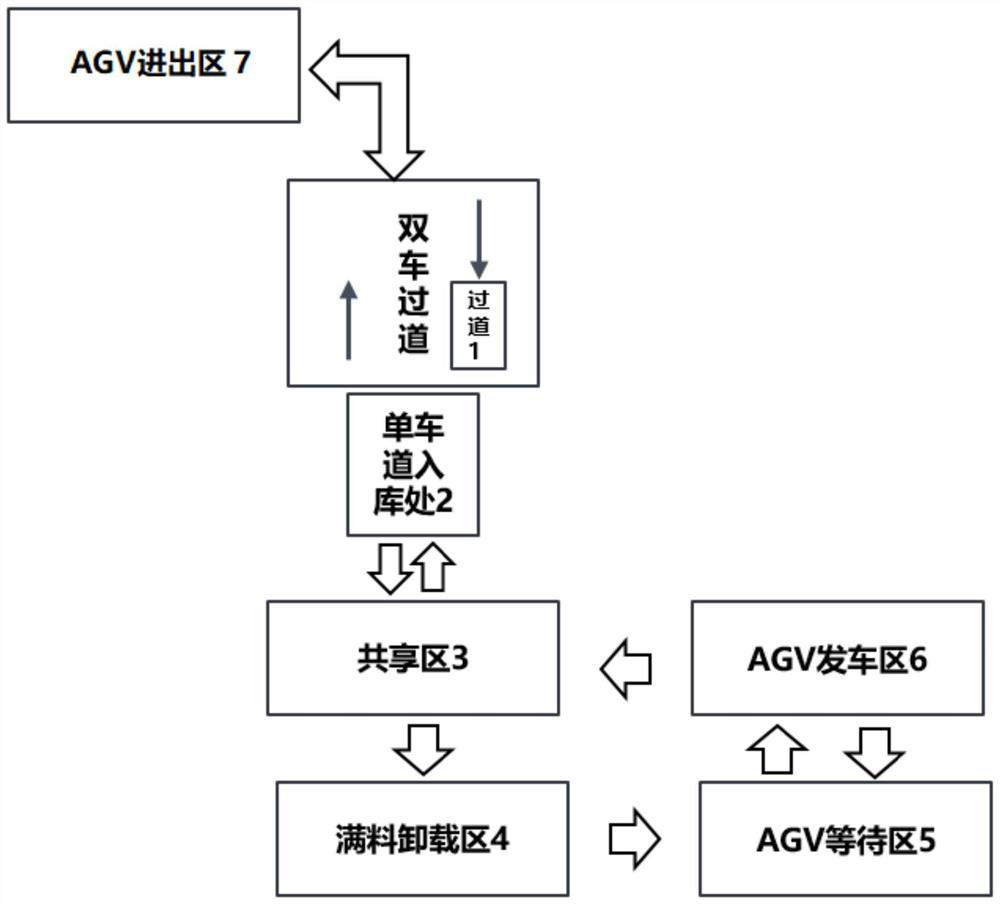

[0039] to combine figure 1 , the present invention is a small-area operation method for AGV handling and sending and receiving, comprising the following operation steps:

[0040] S1. The first AGV goes to the full material unloading area 4, unloads the material, and then goes to the AGV waiting area 5, the second AGV goes to the shared area 3, and the third AGV goes to the aisle 1.

[0041] S21. The AGV goes to the shared area 3, passes through the storage place 2 and the aisle 1, and then returns to the AGV access area 7.

[0042] S2. The first AGV g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com