Extruder hopper for polyethylene particle production

A technology of polyethylene granules and machine materials, which is applied in the field of extruder hoppers for polyethylene granule production, can solve the problems of user limb involvement and injury, and achieve the effect of preventing entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

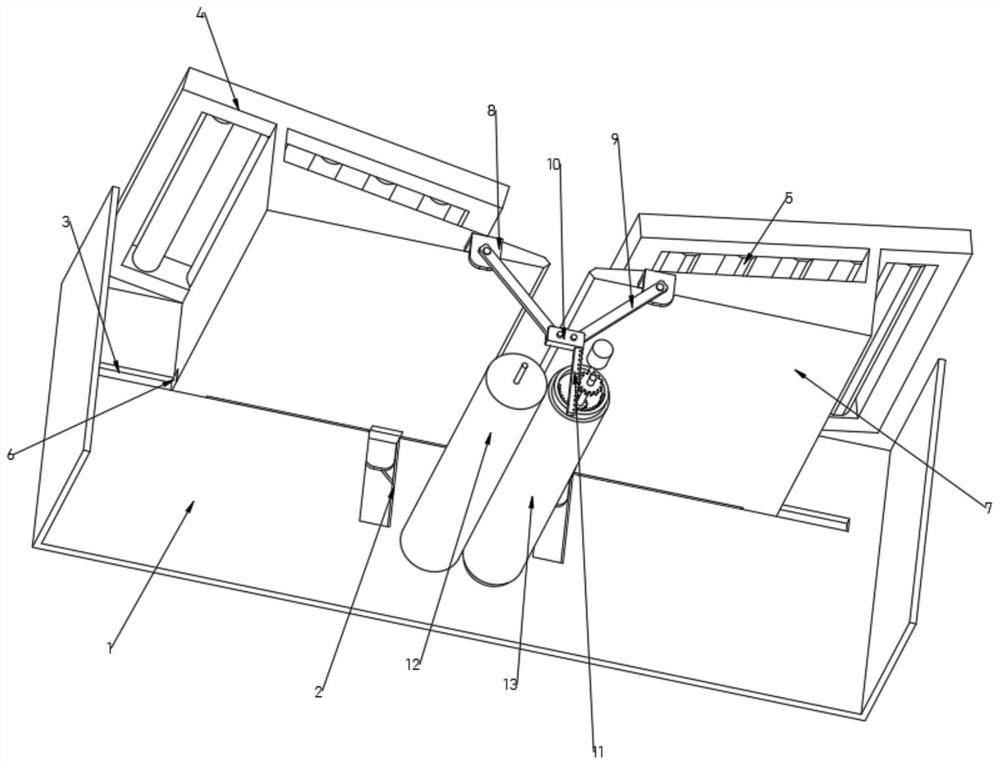

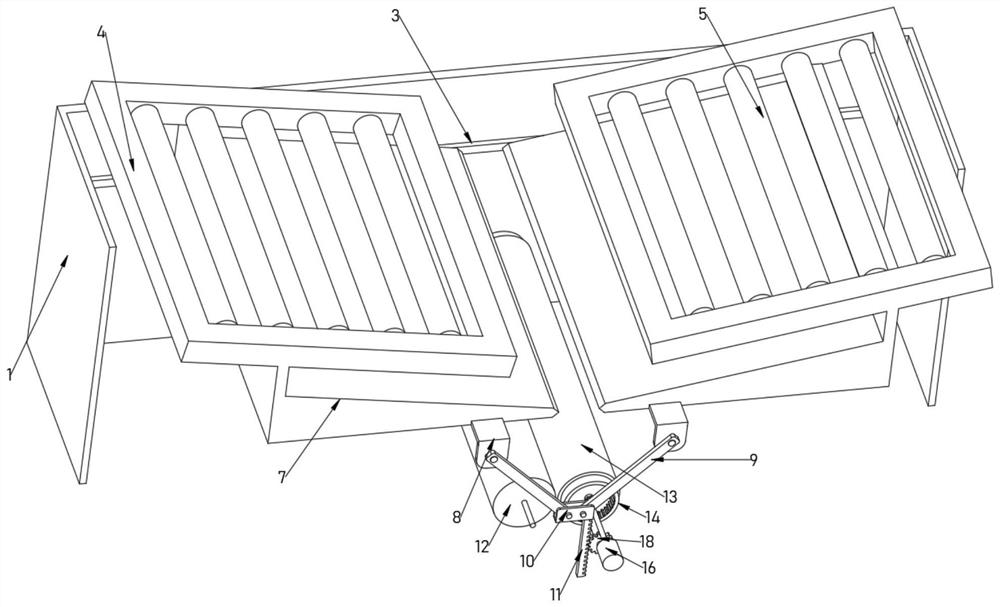

[0035] as attached figure 1 to attach Figure 8 Shown:

[0036] The present invention provides an extruder hopper for polyethylene granule production, which includes: a bucket body 1 and a bracket 4, the inside of the bucket body 1 is provided with a longitudinal through groove 2, and the inside of the bucket body 1 is also provided with a transverse guide Groove 3, guide groove 3 is positioned at the upper side of through groove 2, support 4 is a frame structure, and the inside of support 4 is also connected with guide roller 5 in a linear array, and the lower side of support 4 is fixedly connected with cutting assembly 7, cut off Component 7 is a cutting knife, and two cutting components 7 are oppositely installed.

[0037] refer to Figure 1-3 , the rear end surface of the cut-off assembly 7 is fixedly connected with a slider 6, and the cut-off assembly 7 is slidably connected to the inner side of the guide groove 3 provided inside the bucket body 1 through the slide blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com