Stirring device and heat preservation and sound insulation board pouring system

A technology of mixing device and mixing barrel, which is applied to cement mixing device, unloading device, supply device, etc., can solve the problems that the pouring amount cannot meet the design requirements, the deviation of the slurry weight, and the blockage, so as to facilitate cleaning and maintenance, and ensure the material Density, reducing the effect of hanging on the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

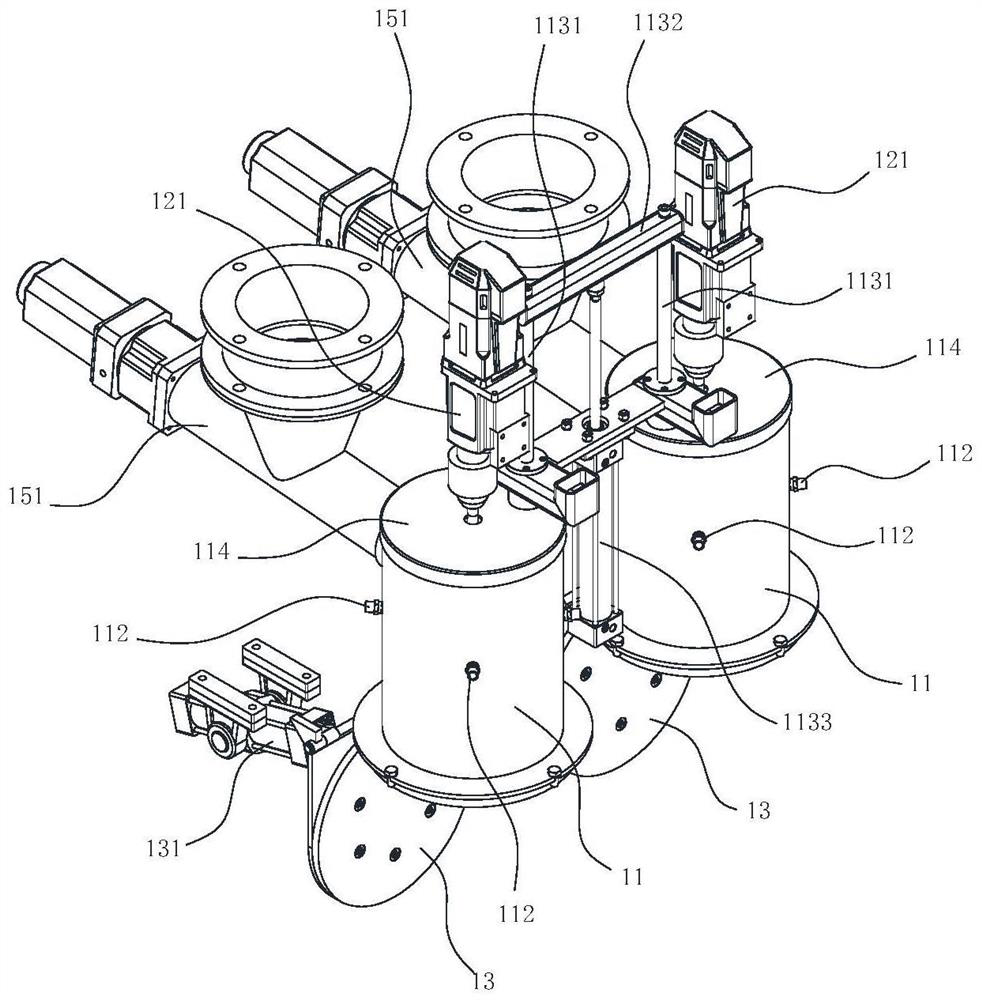

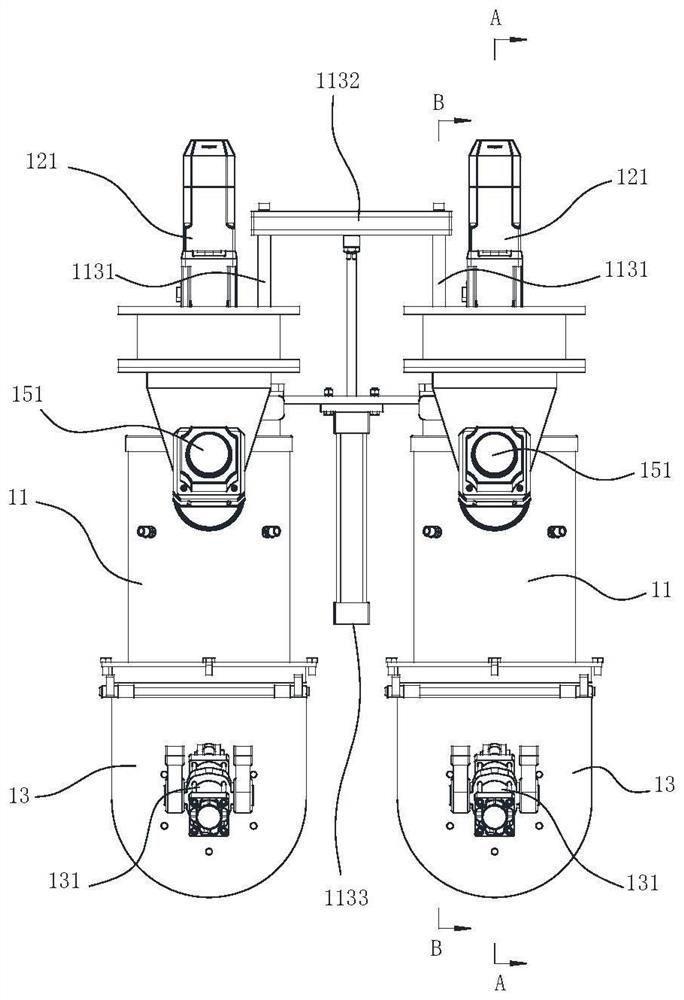

[0047] like Figure 1-4Shown, be a kind of mixing device of the present invention, comprise: mixing barrel 11, have the barrel wall of straight cylinder shape, the barrel wall lower end has discharge port, the caliber of described discharge port is consistent with the internal diameter of described barrel wall; Stir The paddle 12 includes a blade and a rotating shaft fixed to the blade, the blade is located in the mixing tank 11, and the rotating shaft is connected to the main shaft of the mixer 121; the valve 13 is located below the discharge port and includes a valve plate hinged with the frame A valve plate driving element 131 for driving the valve plate to turn over is provided between the valve plate and the frame, and when the valve plate is turned over to realize the opening or closing of the discharge port, the valve plate driving element 131 in this embodiment is a piston Cylinder, the cylinder body of the piston cylinder is hinged with the rack provided at the bottom...

Embodiment 2

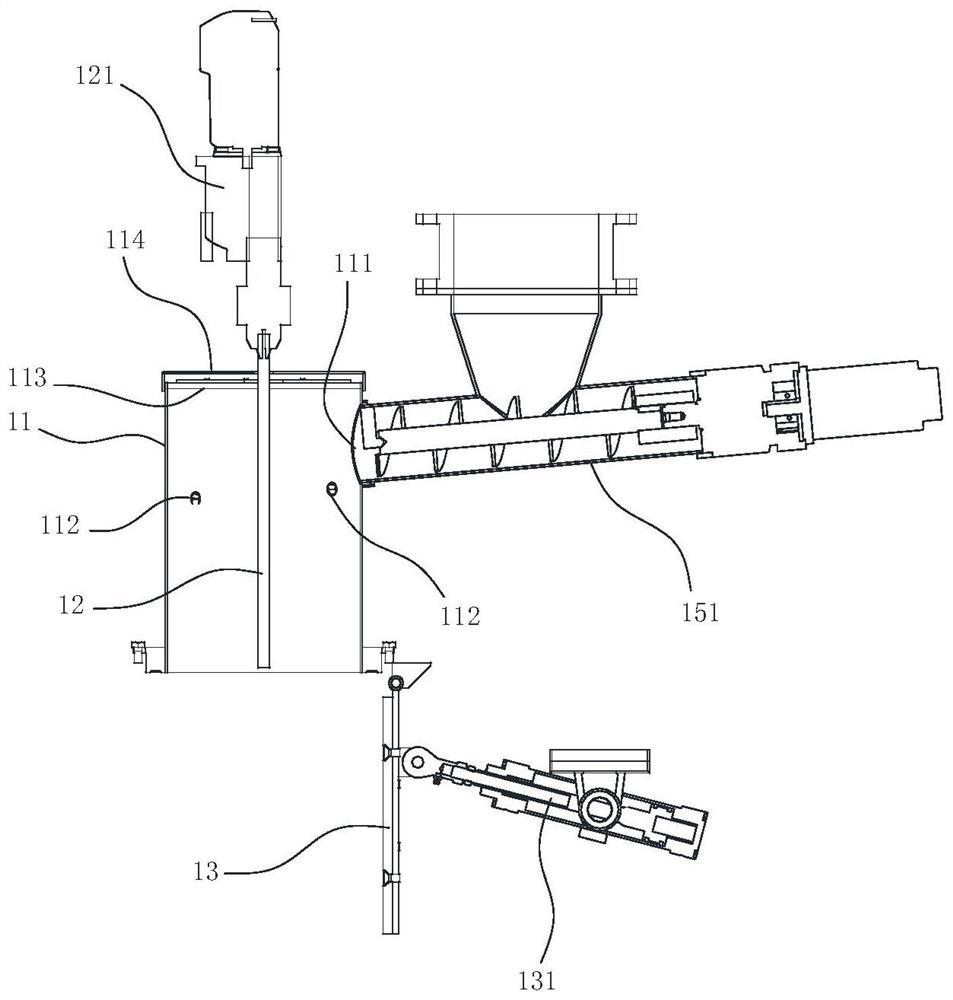

[0053] like Figure 10 , 11 As shown, a thermal insulation and sound insulation board pouring system includes the stirring device described in Embodiment 1, and a feeding mechanism. The feeding mechanism includes a storage hopper (not shown in the figure) and a quantitative delivery mechanism 151. The quantitative delivery mechanism 151 The storage hopper is connected to the feeding port 111 of the mixing tank 11, which is used to quantitatively transport powder materials into the mixing tank 11; the liquid supply system includes a liquid storage tank 16 and an infusion pipeline 161, and the infusion pipeline 161 will store The liquid tank 16 is connected with the nozzle 112 and is used for delivering the liquid solvent into the mixing tank 11 , and the infusion pipeline 161 is provided with a flow valve. The mold conveying mechanism includes a slideway 17 and a pushing mechanism 171. The slideway 17 is located below the mixing bucket 11, and the pushing mechanism 171 is reci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com