High-chroma impact-resistant polystyrene and its preparation method and preparation device

A technique for preparing polystyrene, which is applied in the field of synthetic resin, can solve problems such as corroding equipment, affecting the appearance of products, and affecting the color of high-impact polystyrene products, achieving the effect of reducing wall hanging and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

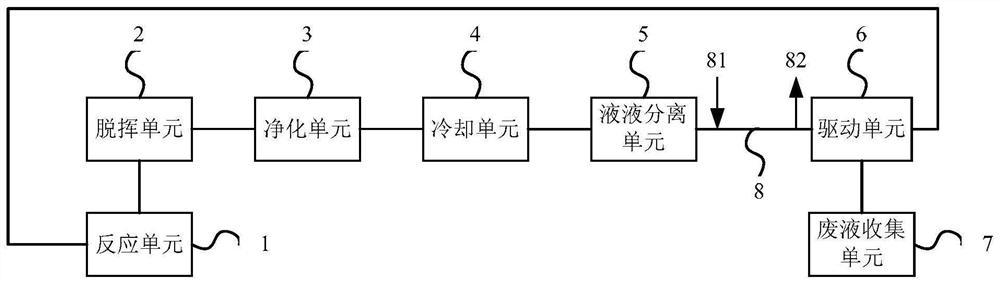

[0027] This embodiment provides a preparation device for high-chroma impact-resistant polystyrene, figure 1 For the preparation device of high-chroma impact-resistant polystyrene provided in the embodiment of the present invention, please refer to figure 1 , the device includes a reaction unit 1, a devolatilization unit 2, a purification unit 3, a cooling unit 4, a liquid-liquid separation unit 5, a drive unit 6 that are connected in sequence, and the drive unit 6 is connected with the reaction unit 1 and the waste liquid collection unit 7 respectively. Specifically, the drive unit 6 is communicated with the reaction unit 1 and the waste liquid collection unit 7 through the tee respectively, and when the liquid in the liquid-liquid separation unit 5 needs to be input to the reaction unit 1 through the drive unit 6, the tee can be rotated to make the The drive unit 6-reaction unit 1 road is unblocked. When the liquid in the liquid-liquid separation unit 5 needs to be input to t...

Embodiment 2

[0031] In this example, the preparation device in Example 1 is used to prepare high-chroma impact-resistant polystyrene.

[0032] 1. Material preparation

[0033] 7 parts by weight of rubber, 83 parts by weight of styrene, and 10 parts by weight of ethylbenzene, wherein the rubber is a mixture of linear structure rubber and star structure rubber in a mass ratio of 1:1. The volatile matter (moisture) of the linear structure rubber is 0.5%, and the chloride ion content is 0.08%; the volatile matter (moisture) of the star-shaped structure rubber is 0.6%, and the chloride ion content is 0.2%.

[0034] 2. Reaction

[0035] In the reaction unit 1, the above-mentioned rubber was dissolved in styrene and ethylbenzene. After the rubber was fully dissolved, the temperature was raised to 128° C. for high-temperature polymerization. When the polymerization conversion rate was 75%, the reaction slurry was input to the devolatilization unit 2 After devolatilizing at a high temperature of ...

Embodiment 3

[0040] In this example, the preparation device in Example 1 is used to prepare high-chroma impact-resistant polystyrene.

[0041] 1. Material preparation

[0042] 8 parts by weight of rubber, 80 parts by weight of styrene, and 12 parts by weight of ethylbenzene, wherein the rubber is a mixture of linear structure rubber and star structure rubber in a mass ratio of 2:3. The volatile matter (moisture) of the linear structure rubber is 0.7%, and the chloride ion content is 0.1%; the volatile matter (moisture) of the star structure rubber is 0.8%, and the chloride ion content is 0.25%.

[0043] 2. Reaction

[0044] In the reaction unit 1, the above-mentioned rubber was dissolved in styrene and ethylbenzene. After the rubber was fully dissolved, the temperature was raised to 130° C. for high-temperature polymerization. When the polymerization conversion rate was 78%, the reaction slurry was input to the devolatilization unit 2 After devolatilizing at a high temperature of 225°C a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com