A method for the continuous preparation of pectin and fiber from fruit

A fruit and pectin technology, applied in the direction of food science, etc., can solve the problems of complicated process, high price and cost, and poor effect of water absorption and expansion, and achieve the effect of improving product quality, improving efficiency, and reducing wall hanging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The present embodiment provides a method for continuously preparing pectin and fiber from fruit, comprising the following steps:

[0055] Step 1, extract the fruit juice and separate to obtain the solid component, heat the solid component with high-temperature hot water and filter to obtain the filtrate 1 and the residue 1;

[0056] Step 2, adding residue 1 to water, heat preservation treatment under acidic conditions at high temperature and filtering to obtain filtrate 2 and residue 2;

[0057] Step 3, combining filtrate one and filtrate two to remove impurities and extract pectin;

[0058] Step 4, Residue 2 is subjected to high-temperature alkali treatment before bleaching or high-temperature alkali treatment after bleaching, and then the solids are collected to obtain Residue 3, wherein the high-temperature alkali treatment is to add Residue 2 to water and keep warm at high temperature under alkaline conditions deal with;

[0059] Step 5: Mix the residue 3, water a...

Embodiment 2

[0071] In this embodiment, the preparation of pectin and fiber from citrus fruits is taken as an example. For the different preparation processes provided in Example 1, the following experiments were carried out respectively:

[0072] 1. High temperature hot water insulation treatment process

[0073] Take the dry powder in step (1) of Example 1, add water according to the solid-to-liquid ratio of 1:15, keep warm at 90°C for 30 minutes, filter, collect the filtrate and residue for later use.

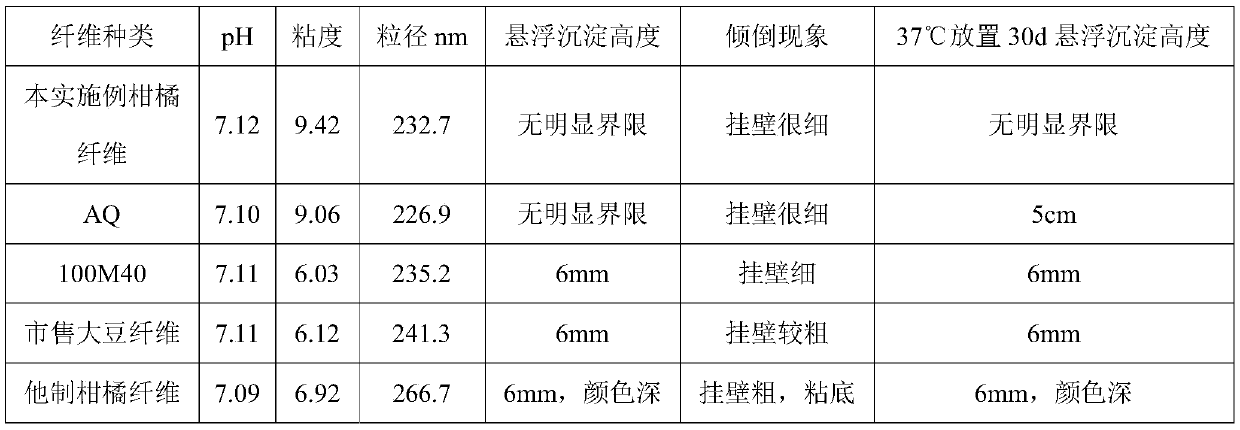

[0074] The prepared fiber (other steps are the same except for heat preservation and cooking) was applied to peanut milk, and the specific results are shown in the table below.

[0075] Fiber Treatment pH Viscosity cp particle sizenm suspended sediment height dumping phenomenon Warm cooking 7.26 7.68 237.9 no clear boundaries thinner wall Uncooked 7.29 6.00 241.5 0.7cm Thick wall

[0076] Note: The viscosity measurement method is 61# rotor...

Embodiment 3

[0104] Squeeze fresh citrus fruit juice, dry the dregs of peel and pulp at 65°C, pulverize, pass through an 80-mesh sieve, and collect the dry powder for later use. Weigh 40g of dry powder, add water at 100°C according to the solid-to-liquid ratio of 1:20, keep warm at 100°C for 5min, filter, and collect the residue for later use. Convert the residue 1 to the weight of dry matter, add water according to the solid-to-liquid ratio of 1:20, adjust the pH to 2, keep it at 80°C for 90 minutes, filter, and collect the residue 2. Convert the residue to the weight of dry matter, weigh water according to the solid-to-liquid ratio of 1:20, adjust the pH to 12, keep warm at 80°C for 90min, cool down to 40°C, and add 6% H 2 o 2 , keep warm at 40°C for 20min, filter, and collect the residue III. Convert the residue to dry matter weight, weigh hot water according to the solid-to-liquid ratio of 1:60, add CMC with 10% dry matter weight of the residue, stir for 15 minutes, adjust the pH of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com