Contact network annular steel pipe column weld joint grinding equipment

A steel pipe column and catenary technology, which is applied in the direction of grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems of high labor intensity of operators, high technical level of operators, low production efficiency, etc., and achieve grinding and polishing The effect of good quality, simple structure design and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0021] The present invention is further described in the drawings and in conjunction with the specific embodiments below.

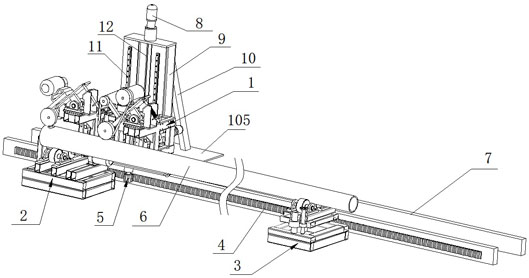

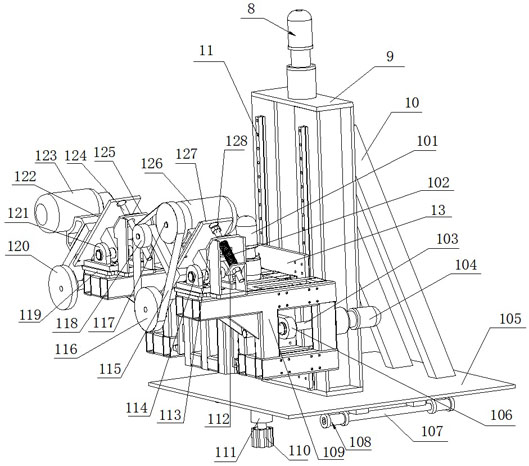

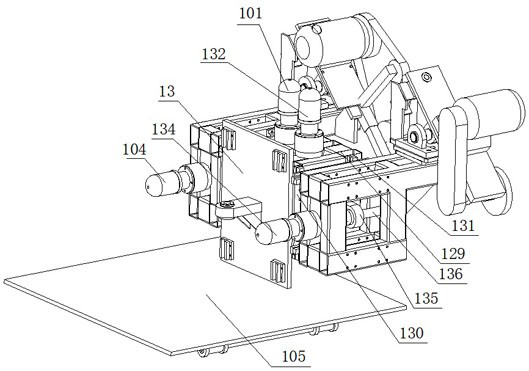

[0022] like Figure 1 to 5 , The present embodiment includes two tracks 7, the host 1 and the linkage comprises a welded steel pipe column 6 can remain in the horizontal position the large end of the roller means 2 and the small end of the steel column support mechanism roller mechanism 3.

[0023] The large end support roller mechanism comprises a base 2 Ⅰ201, two large end rollers 202 and 204, the motor and gear plate 203 Ⅰ205. Two roller large end is formed between the steel support column 202 and the large end 204. Both ends of the major side rollers 202 and 204, respectively, by the output shaft of the motor Ⅰ205 206 is rotatably secured to the base Ⅰ201, fixed to the base via a coupling Ⅰ201 bearing housing and wherein a large end of the roller shaft 204 rigid connection. Gear 203 is fixed to the rear end of the base plate located at the large end Ⅰ201 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com