An air tightness detection device for filter element production

A technology of air tightness detection and filter elements, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and by measuring the increase and deceleration rate of the fluid, etc., which can solve the problems of inability to directly reflect the test results, poor detection efficiency of the device, and inaccurate detection and other problems, to achieve the effect of easy observation of test results, convenient operation and use, and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

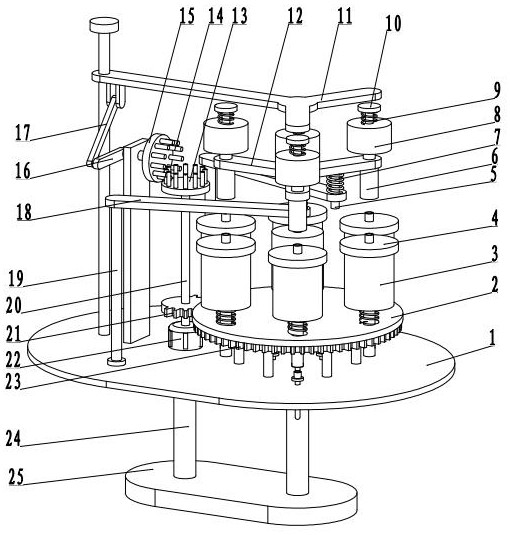

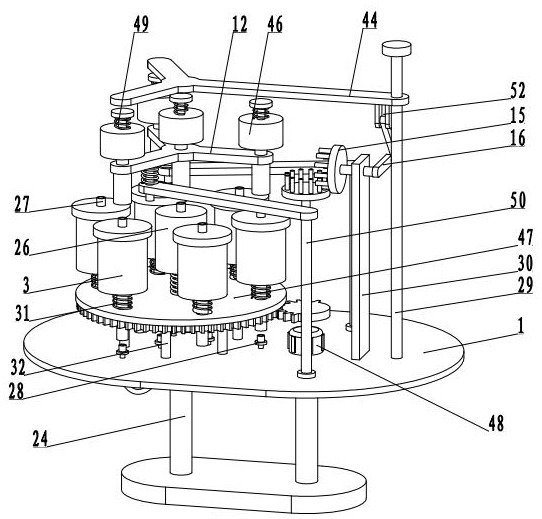

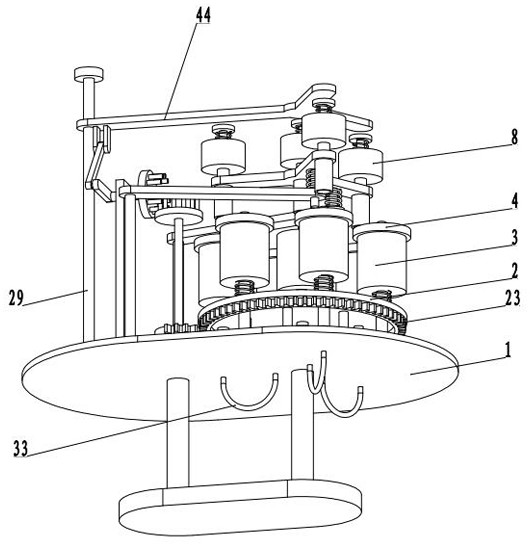

[0030] see Figure 1-9 , an air tightness detection device for filter element production, comprising a bottom plate 1, and further comprising:

[0031] The mounting plate 2 is arranged above the bottom plate 1, the bottom of the mounting plate 2 is fixedly connected with the supporting legs 32, and the supporting legs 32 are slidingly connected with the bottom plate 1, and a plurality of sealing cylinders 3 are arranged on the mounting plate 2, and a standard pressure is set between the sealing cylinders 3 barrel 26;

[0032] The inflation mechanism 46 that is arranged on the top of the sealing cylinder 3 includes a mounting frame 12, the mounting frame 12 is a triangular rod structure, and an inflating cylinder 8 is fixedly arranged on the mounting frame 12 above the sealing cylinder 3 and the standard pressure cylinder 26. 8 is provided with a telescopic assembly 49, the bottom of the installation frame 12 below the inflatable cylinder 8 is fixedly connected to the air stor...

Embodiment 2

[0037] see Figure 1-9 , the other content of this embodiment is the same as that of Embodiment 1, except that the telescopic assembly 49 includes a piston rod 10 arranged above the inflatable cylinder 8, the piston rod 10 extends into the inflatable cylinder 8, and is connected with the inflatable cylinder 8 Slidingly connected, one end of the piston rod 10 is fixedly connected with the drive rod of the inflator 8, the piston rod 10 is a T-shaped structure, and the reset member 9 is sleeved on the piston rod 10, and the reset member 9 can be used with a telescopic The nature of the spring or elastic metal sheet.

[0038] The support assembly 50 includes a load-bearing beam 18 arranged below the mounting frame 12, and a load-bearing column 19 is fixedly connected between the load-bearing beam 18 and the bottom plate 1. One side of the load-bearing beam 18 slides through a limit column 5, and the limit column 5 The top is fixedly connected with the installation frame 12, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com