Vortex box, waste gas collection method and waste gas collection and disposal device

A disposal device and waste gas collection technology, which is applied to components, separation methods, chemical instruments and methods of elastic fluid pumping devices, etc., can solve the problems of low collection efficiency and high energy consumption of waste gas collection, and achieve reduced turbulence, The effect of reducing energy cost and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

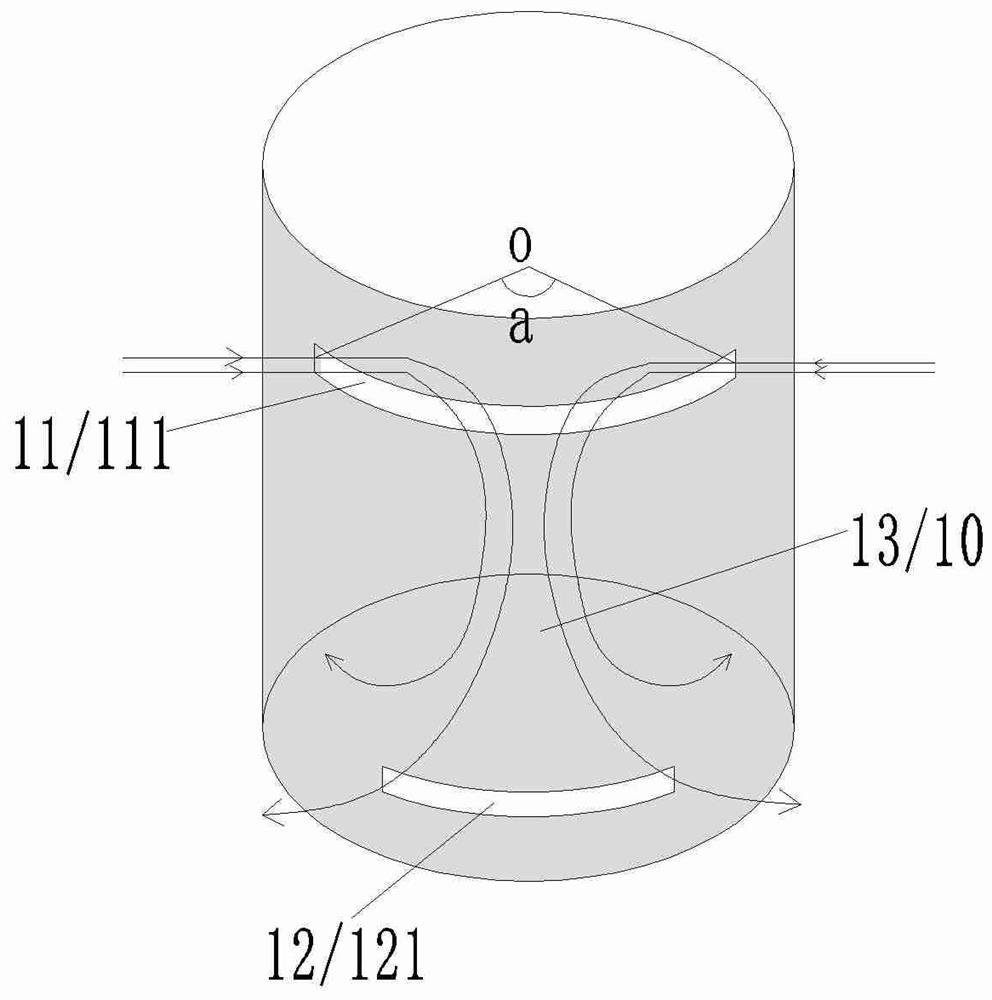

[0142] This embodiment provides a swirl box 1, please refer to figure 1 The vortex box 1 is provided with a cylindrical vortex chamber 10, and the upper side of the vortex chamber 10 is provided with an air intake assembly 11 and an air outlet assembly 12. The air intake assembly 11 only includes a first air inlet 111, and the air outlet assembly 12 is arranged on Directly below the air inlet assembly 11, the air outlet assembly 12 only includes the first air outlet 121, and the orthographic projection of the angle formed by the two ends of the first air inlet 111 and the center point O of the vortex chamber 10 on the horizontal plane is a , in this embodiment, a is 120 degrees, and the vortex chamber 10 is used as a working space. During operation, exhaust gas will be generated in the vortex chamber 10 .

[0143] The above-mentioned vortex box 1, the intake air that enters through the first air inlet 111 can be decomposed into: the first component intake air that enters throu...

Embodiment 2

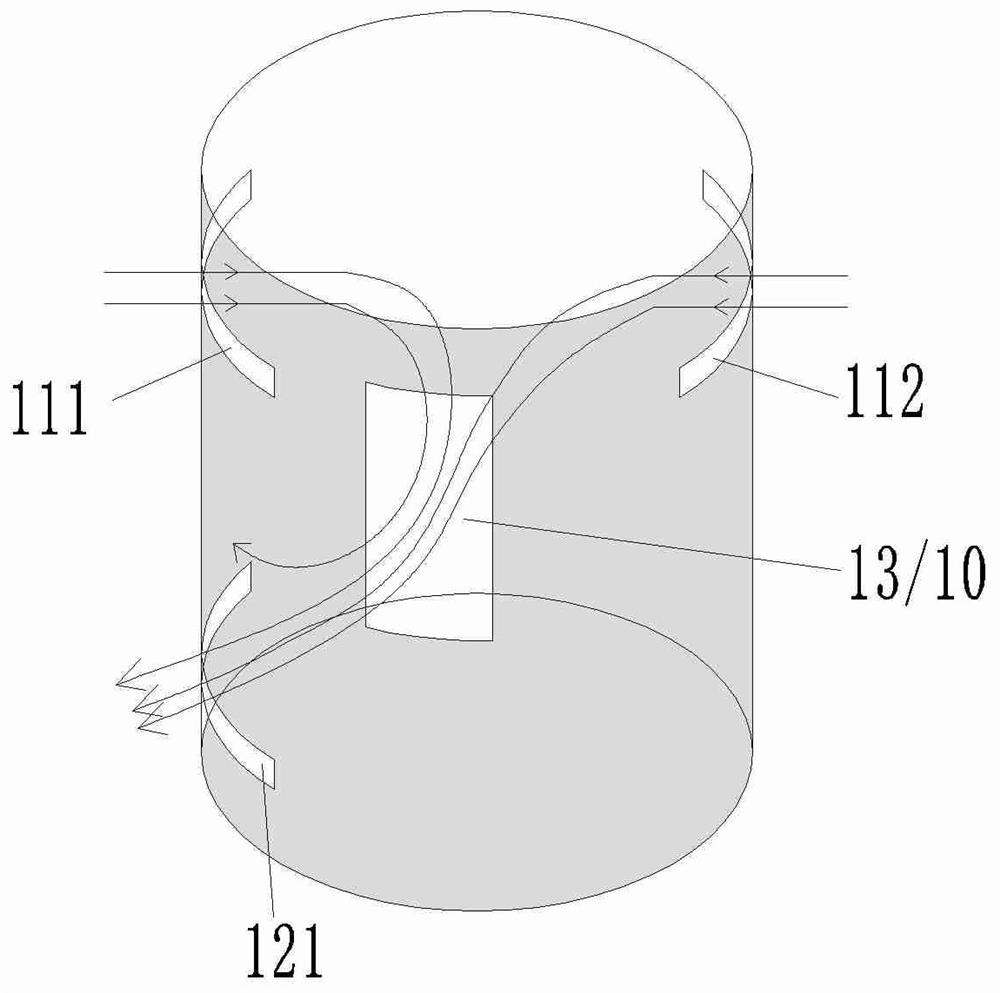

[0153] This embodiment provides a swirl box 1, please refer to figure 2 The vortex box 1 is provided with a cylindrical vortex cavity 10, the upper side of the vortex cavity 10 is provided with an air inlet combination 11, and the air intake combination 11 includes a first air inlet 111 and a second air inlet 112 arranged oppositely, The air outlet assembly 12 is arranged directly below the first air inlet 111, the air outlet assembly 12 only includes the first air outlet 121, and the waste gas channel 13 is arranged at the first air inlet 111, the second air inlet 112 and the first air outlet 121 In the triangular area between, the working space is located directly in front of the waste gas passage 13.

[0154] Above-mentioned vortex box 1, the first intake airflow that enters through the first air inlet 111 and the second intake airflow that enters through the second air inlet 112 form opposite intake airflow, the first outlet airflow that flows out through the first air ou...

Embodiment 3

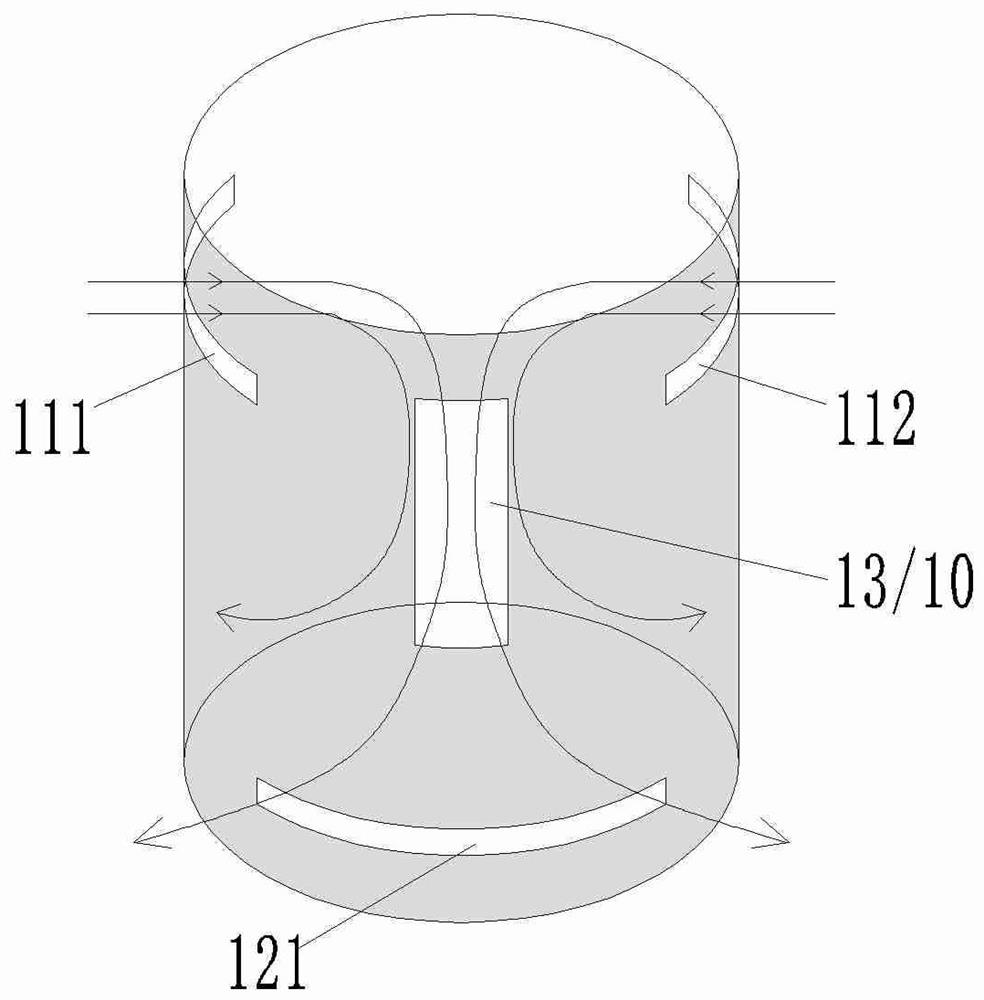

[0163] This embodiment provides a swirl box 1, please refer to image 3 The vortex box 1 is similar to the vortex box 1 provided in Embodiment 2, except that the first air outlet 121 is equidistant from the first air inlet 111 and the second air inlet 112 .

[0164] The above-mentioned vortex box 1, the first intake air that enters through the first air inlet 111 and the second intake air that enters through the second air inlet 112 constitute the opposite intake air, and the outlet air that flows out through the first air outlet 121 can be decomposed into : the first component of the airflow near the first air inlet 111 side, and the second component of the airflow near the second air inlet 112 side, the first airflow is opposite to the first component of the airflow direction, the second The direction of movement of the inlet airflow is opposite to that of the second component of the outlet airflow. When the exhaust device 3 connected to the air outlet assembly 12 was worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com