Meshing method of movable-tooth gear and variable-diameter continuously variable transmission applying same

A technology of continuously variable transmission and moving teeth, which is applied in the direction of gear transmission, components with teeth, belt/chain/gear, etc. It can solve the problems of affecting transmission efficiency, power loss, and small power, and achieves overcoming power bottlenecks, Effect of no power loss and small power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

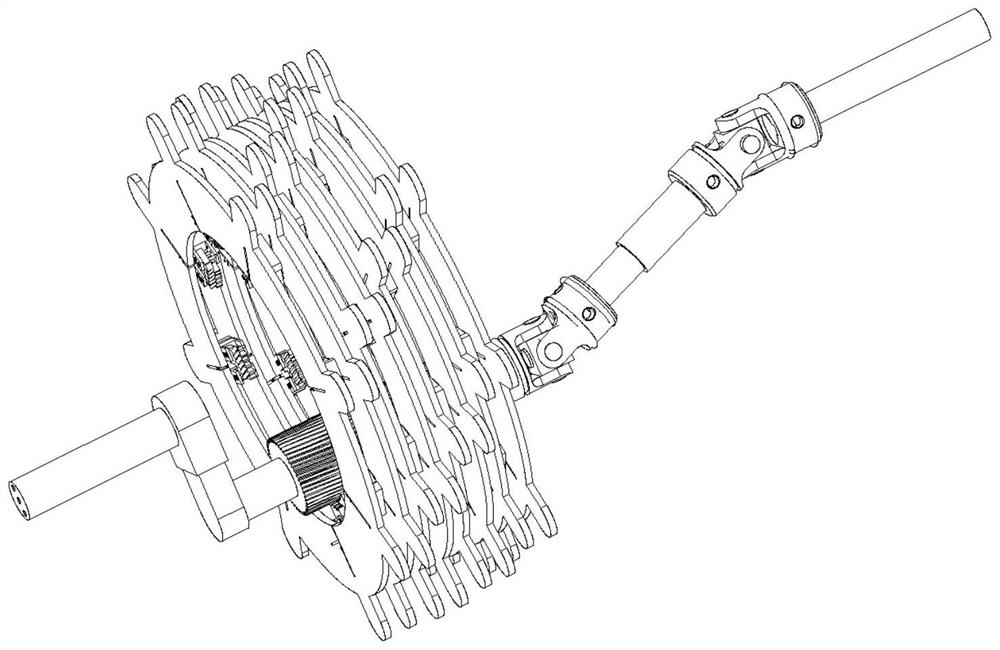

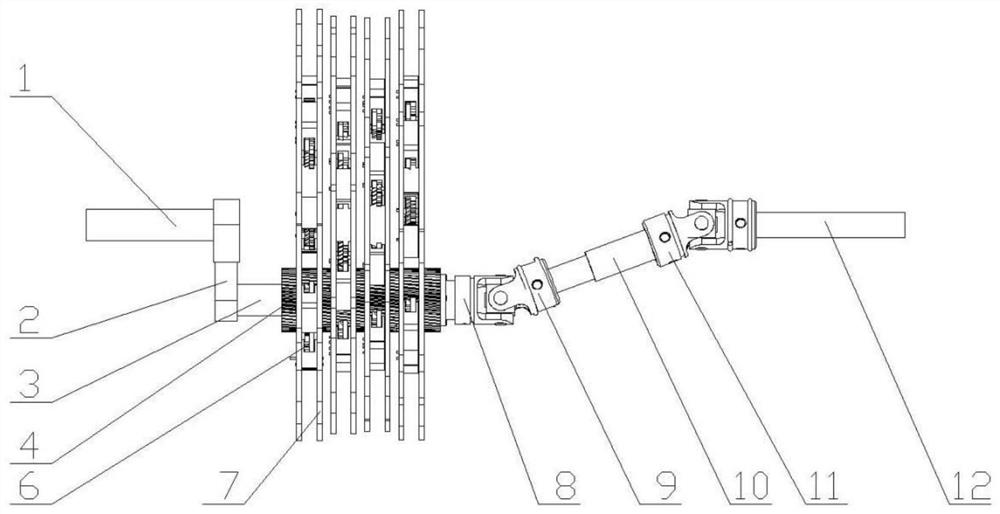

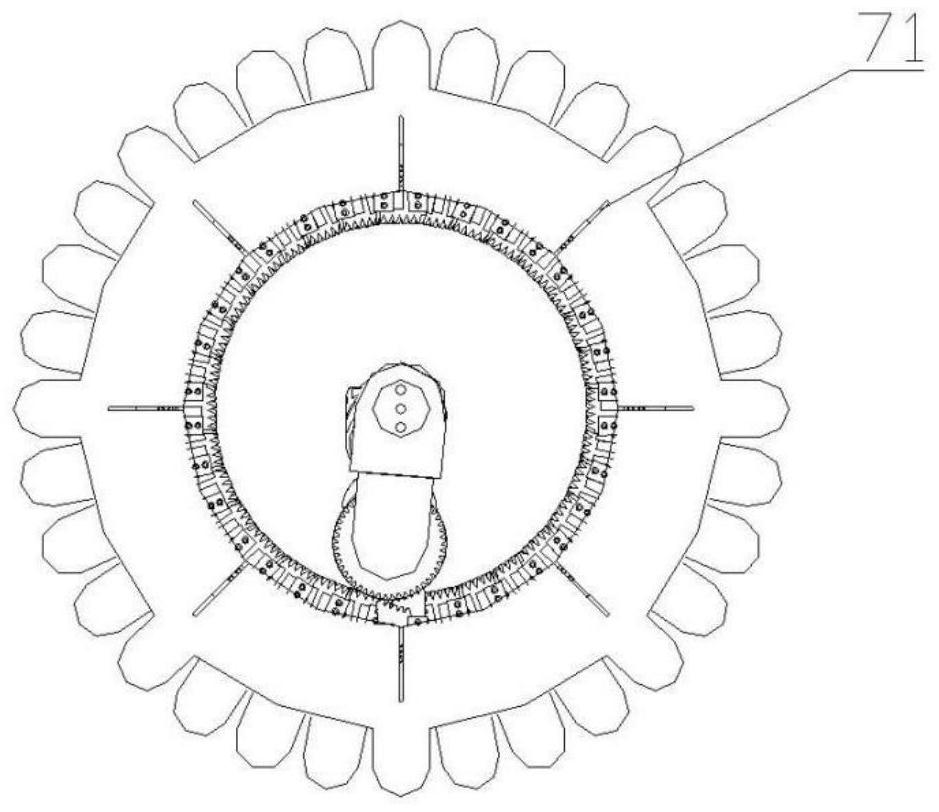

[0035] A method for meshing movable gears, in which movable gears 6 are meshed with planetary shaft teeth 4 (see figure 1 , 2 , 3), movable tooth gear 6 (see Figure 4 ) includes: two parallel and staggered movable tooth blocks 6-1 and a seesaw mechanism. In this embodiment, the tooth shape of the movable tooth block 6-1 is helical; -6, the first pin shaft 6-2, the seesaw shaft 6-3, the second pin shaft 6-4, the seesaw plate 6-5 and two vertical plates 6-7; wherein, the tooth block T-shaped base 6- 6 is a boss structure, and the two vertical plates 6-7 are connected to the seesaw 6-5 through the second pin shaft 6-4; the seesaw 6-5 is connected to the tooth block T-shaped base 6 through the seesaw shaft 6-3 -6 boss connection; two movable tooth blocks 6-1 are respectively connected with two vertical plates 6-7 through the first pin shaft 6-2, and the movable tooth block 6-1 is connected with the vertical plate 6-7 A spring 6-8 is sleeved on the first pin shaft 6-2 between t...

Embodiment 2

[0049] The difference from Embodiment 1 is that in the movable gear 6, the first pin shaft 6-2 is not axially parallel to the movable tooth block 6-1, and the axis of the first pin shaft 6-2 is parallel to the movable tooth block 6 -1 The tooth profile line has an included angle in the projection direction of the top view, and the range of the included angle is 89.5°. The movable tooth block 6-1 can still slide axially on the first pin shaft 6-2. Figure 7 As shown by the two-way arrow in middle A, when there is a gap in meshing, the movable tooth block 6-1 is under the thrust of the force surface, because there is a certain angle, there is a gap along the first pin shaft 6-2 in the transverse direction. Side movement eliminates meshing backlash. Slide to a certain range, to the end of meshing.

[0050] The variable-diameter movable gear CVTs provided in Embodiment 1 and Embodiment 2 have a transmission torque that is more than three times that of the existing friction CVT te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com