Two-dimensional Cu-MOF fluorescent probe material as well as preparation method and application thereof

A fluorescent probe and reaction technology, applied in the field of fluorescent sensors, can solve the problems of inability to carry out large-scale popularization and detection, and achieve the effects of easy operation and implementation, strong sensitivity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

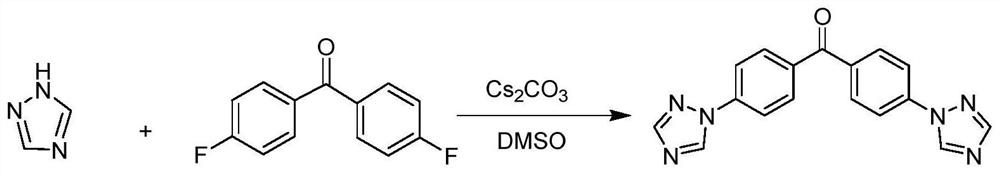

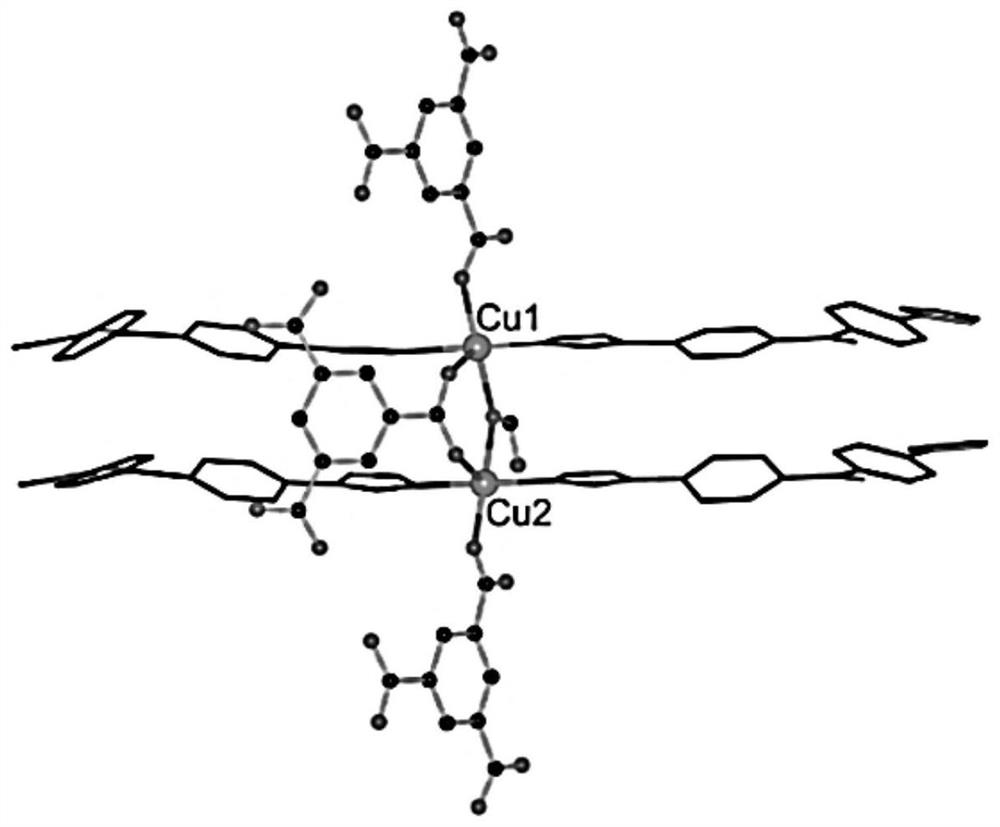

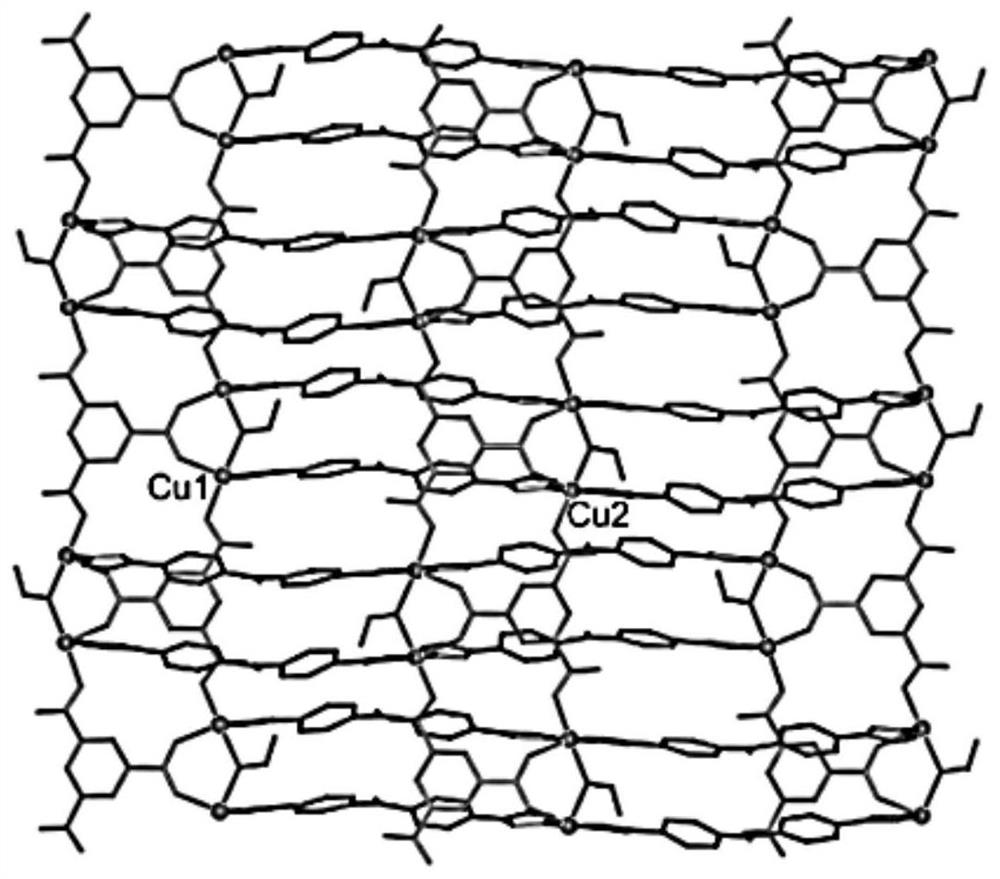

Method used

Image

Examples

Embodiment 1

[0046] A preparation method of a two-dimensional Cu-MOF fluorescent probe material, comprising the following steps:

[0047] Step 1: Prepare 3mL of H 2 O and 2mL DMF mixed solution.

[0048] Step 2, at room temperature, weigh L (0.0316g, 0.1mmol) and Cu (NO 3 ) 2 ·3H 2 Add O (0.0242 g, 0.1 mmol) into the above solution and ultrasonically dissolve it for 10-20 min, then add auxiliary ligand 1,3,5-BTC (0.0105 g, 0.05 mmol) and stir for 20-30 min to obtain a suspension.

[0049] Step 3, the suspension was transferred to a 23mL heat-resistant glass kettle with a polytetrafluoroethylene cover, heated to 90°C and kept at a constant temperature for 48h, and the temperature was programmed to cool down (5°C / h) to room temperature to obtain blue blocky crystals.

[0050] Step 4, the above-mentioned gained crystals are filtered through a filter membrane with a pore size of 22 μm, and then 3 mL (V H2O :V DMF =1:1) Washed twice with deionized water and DMF, dried at 90°C for 6 hours,...

Embodiment 2

[0052] A preparation method of a two-dimensional Cu-MOF fluorescent probe material, comprising the following steps:

[0053] Step 1: Prepare 3mL of H 2 O and 2mL DMF mixed solution.

[0054] Step 2, at room temperature, weigh L (0.0316g, 0.1mmol) and CuCl 2 2H 2 Add O (0.0170g, 0.1mmol) to the above solution and ultrasonically dissolve it for 10-20min, then add auxiliary ligand 1,3,5-BTC (0.0105g, 0.05mmol) and stir for 20-30min to obtain a suspension.

[0055] Step 3, the suspension was transferred to a 23mL heat-resistant glass kettle with a polytetrafluoroethylene cover, heated to 95°C and kept at a constant temperature for 55h, and the temperature was programmed to cool down (5°C / h) to room temperature to obtain blue blocky crystals.

[0056] Step 4, the above-mentioned gained crystals are filtered through a filter membrane with a pore size of 22 μm, and then 3 mL (V H2O :V DMF =1:1) Washed twice with deionized water and DMF, dried at 95°C for 6.5 hours, cooled to roo...

Embodiment 3

[0058] A preparation method of a two-dimensional Cu-MOF fluorescent probe material, comprising the following steps:

[0059] Step 1: Prepare 3mL of H 2 O and 2mL DMF mixed solution.

[0060] Step 2, at room temperature, weigh L (0.0316g, 0.1mmol) and CuSO 4 ·5H 2 Add O (0.0250g, 0.1mmol) to the above solution and ultrasonically dissolve it for 10-20min, then add auxiliary ligand 1,3,5-BTC (0.0105g, 0.05mmol) and stir for 20-30min to obtain a suspension.

[0061] Step 3, the suspension was transferred to a 23mL heat-resistant glass kettle with a polytetrafluoroethylene cover, heated to 100°C and kept at a constant temperature for 65h, and the temperature was programmed to cool down (10°C / h) to room temperature to obtain blue blocky crystals.

[0062] Step 4, the above-mentioned gained crystals are filtered through a filter membrane with a pore size of 22 μm, and then 3 mL (V H2O :V DMF =1:1) Washing with deionized water and DMF for 3 times, drying at 100°C for 7 hours, coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com