Clamping structure-based double-charging-barrel hoisting device and method

A technology for hoisting devices and connecting structures, which is applied to chemical instruments and methods, transportation and packaging, and load hanging components, etc. It can solve problems such as bolt misalignment and deformation, and cannot be disassembled, so as to achieve high market application value, ensure connection efficiency and hoisting effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

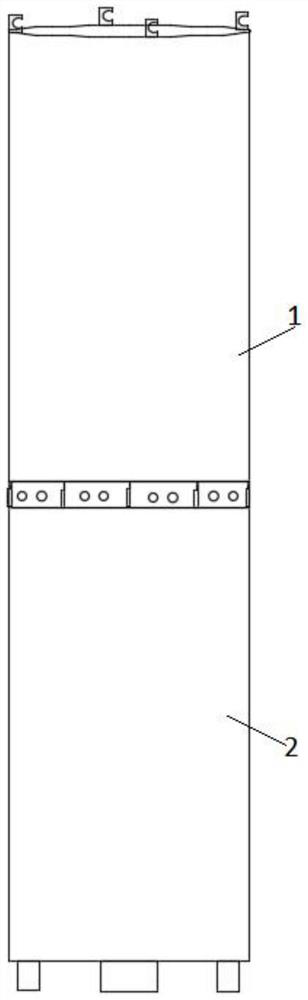

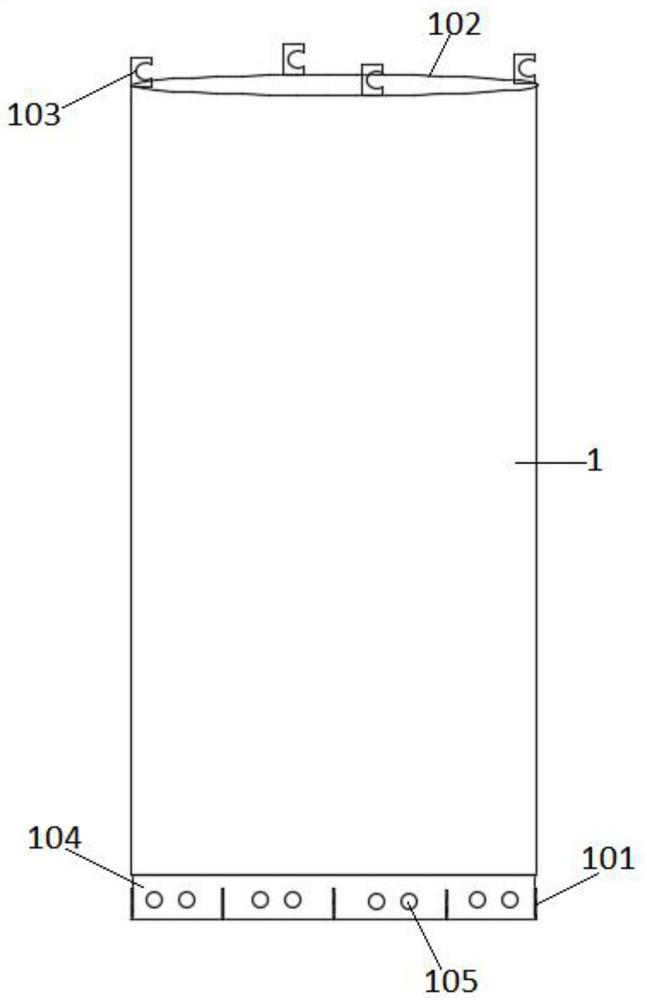

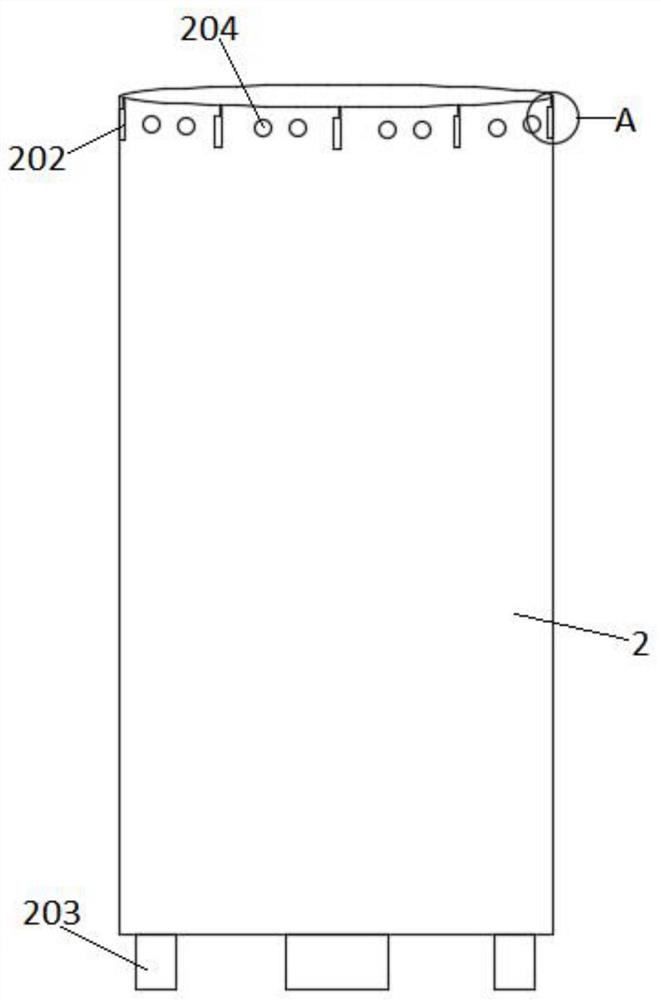

[0030] see Figure 1-5 As shown, the present invention is a double barrel hoisting device based on a clamping structure, including a directional slide rail, an upper barrel 1 and a lower barrel 2; an electric hoist is installed on the directional slide rail; a limit position is installed on the directional slide rail The limiter is used to ensure that the sling of the electric hoist is on the same straight line as the center of the mouth of the drying kettle; the limiter is preferably a conventional rubber limiter in this field; the electric hoist adopts a conventional explosion-proof electric hoist in this field, and its configuration It has fast / slow speed function and overweight reminding function; a sling 3 is installed on the electric hoist; the sling 3 is connected with the upper port of the feeding cylinder 1; The outer wall of the lower end is uniformly welded with a plurality of clamping strips 101 along the annular direction; the clamping strips 101 are vertically ar...

specific Embodiment 2

[0033] This embodiment is further optimized on the basis of specific embodiment one, specifically as follows:

[0034] Such as Figure 1-3 As shown, the upper material cylinder 1 is made of stainless steel; the horizontal cross section of the upper material cylinder 1 is a circular structure; the wall thickness of the upper material cylinder 1 is 2-3mm; the lower material cylinder 2 is made of stainless steel; The horizontal cross-section of the barrel 2 is circular; the wall thickness of the lower barrel 2 is 2-3mm.

specific Embodiment 3

[0036] This embodiment is further optimized on the basis of specific embodiment two, specifically as follows:

[0037] Such as Figure 1-4 As shown, the bottom of the upper material cylinder 1 is a closed structure; the bottom wall of the upper material cylinder 1 is coaxially welded with a positioning ring 104 arranged horizontally; the outer diameter of the positioning ring 104 is 1-2mm less than the outer diameter of the upper material cylinder 1; The height of 104 is 50-80mm; the clip 101 is arranged on the outer wall of the positioning ring 104; the thickness of the clip 101 is 2-3mm, and the length of the clip 101 along the radial direction of the upper material cylinder 1 is 2-5mm; The bottom of the barrel 2 is a closed structure; the bottom wall of the lower barrel 2 is vertically fixed with a plurality of support feet 203; the inlet and outlet notches 201 and the card notches 202 form a stepped structure; the width of the card notches 202 is the size of the in and out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com