Device for clamping silicon wafer in silicon wafer visual detection process

A technology for visual detection and silicon wafers, which is applied in the direction of workpiece clamping devices, manufacturing tools, workbenches, etc., can solve problems such as the inability to realize silicon wafer detection and blind spots caused by visual inspection, and achieve good protection, convenient inspection, and prevention of silicon wafers. The effect of chip damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

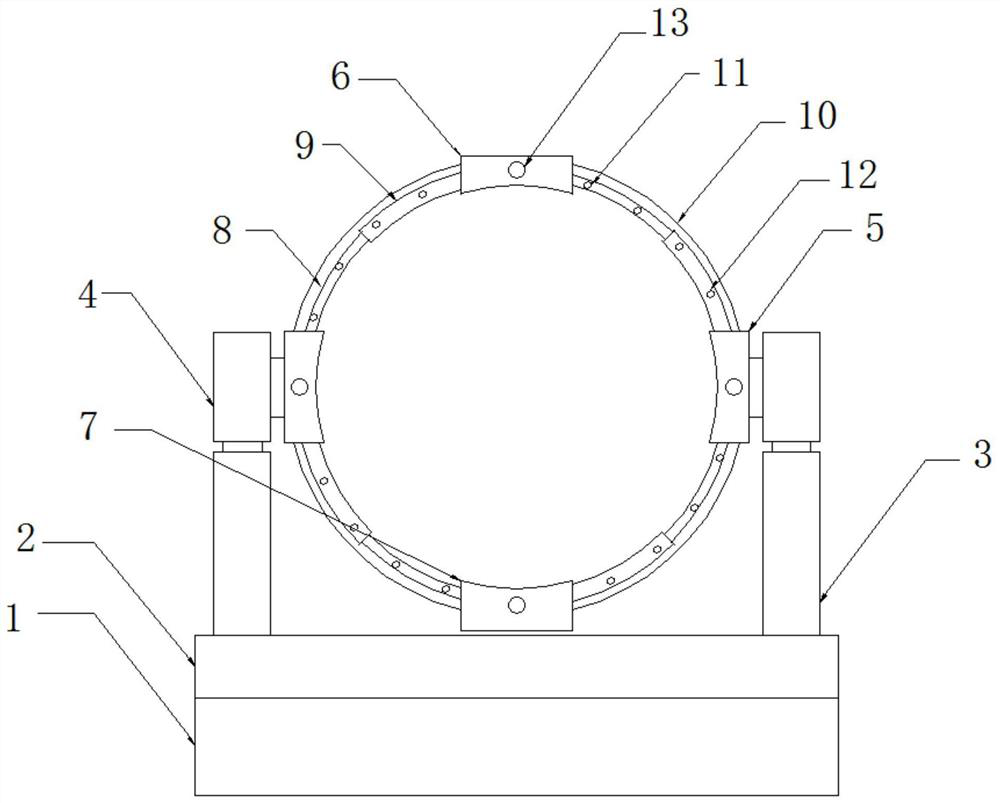

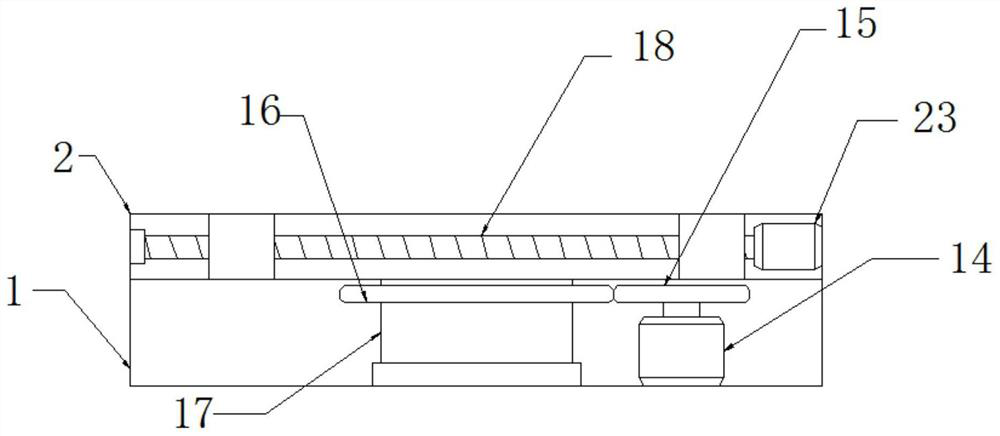

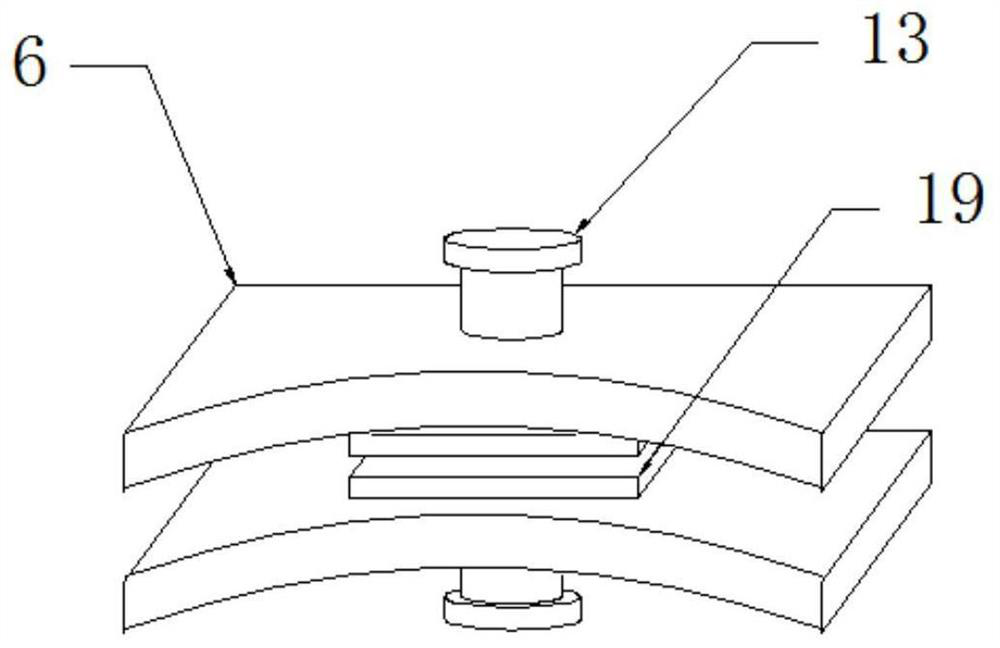

[0026] see Figure 1-5 , the present invention provides a technical solution: a device for clamping silicon wafers in the process of visual inspection of silicon wafers, including a turntable 2, an adjustment column 3, a mounting seat 4 and a clamping mechanism, and the turntable 2 is equipped with There is a driving mechanism for adjusting the position of the adjusting column 3, the driving mechanism can drive the displacement of the adjusting column 3, and the adjusting column 3 is provided with a hydraulic device, the telescopic end of the hydraulic device runs through the adjusting column 3 and is connected with the mounting seat 4, the hydraulic device The work can drive the mounting seat 4 to rise or fall. The clamping mechanism includes two fixed seats 6, two left and right connecting seats 5, a driving seat 7 and a connecting mechanism. Connected to the seat 4, the mounting seat 4 is provided with a connecting block, the bearing is connected to the connecting block, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com