Efficient dust removal environment-friendly equipment for green buildings

A technology of environmental protection equipment and green building, applied in the field of machine-made sand and powder removal, can solve the problems of high energy consumption of vacuuming, dirty clothes, poor vacuuming effect, etc., and achieve the effect of improving dusting effect and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

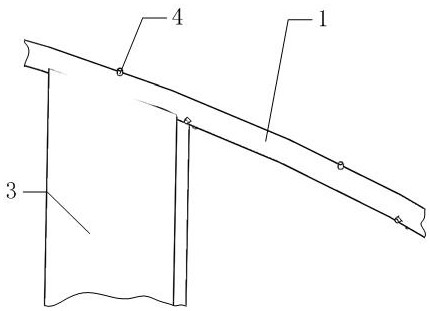

[0048] Embodiment: When using the device designed by the present invention, firstly, the dust suction unit 2 absorbs part of the dust enclosed in the middle, and the remaining dust that is not absorbed passes through the atomizing nozzle in the water pipe 1 after floating out of the dust collection unit 2 4. Spray atomized gas to reduce the remaining dust, and the dust absorption effect can be greatly improved through double-layer absorption.

[0049] When the dust collection unit 2 sucks dust, the motor 10 works to drive the air pump 9 to work, and the air pump 9 sucks air, and the dust in the middle enters the first suction pipe 5 through the second suction pipe 11 and the first suction pipe 5 along with the air. In the suction pipe 5, when the dust and gas driven by the gas enter from the first suction pipe 5, they will enter the second suction pipe 11 along the first suction pipe 5 and combine to enter the second suction pipe. In the air pipe 11, after the gas and dust ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com