A vibration-proof power motor

A motor and power technology, applied in the direction of electric components, electromechanical devices, casings/covers/supports, etc., can solve the problems of reduced motor service life, easy vibration, lack of motor shock absorption protection, etc., to improve stability, Ease of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

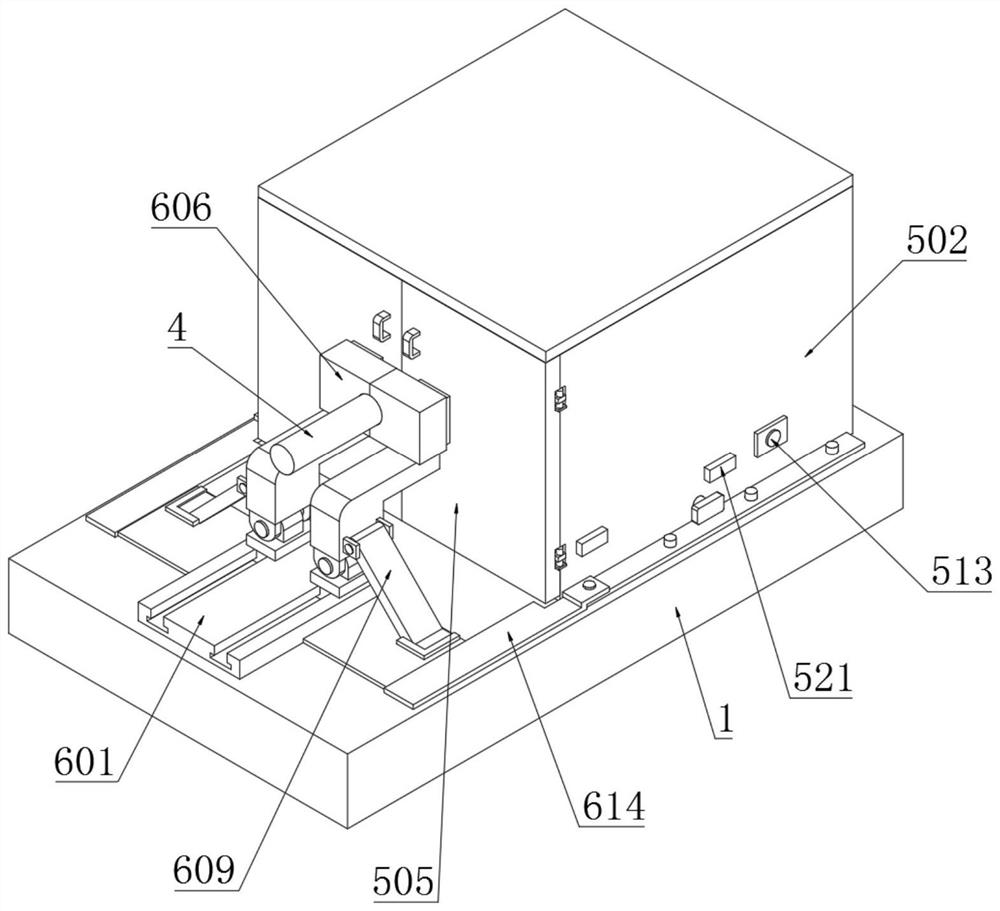

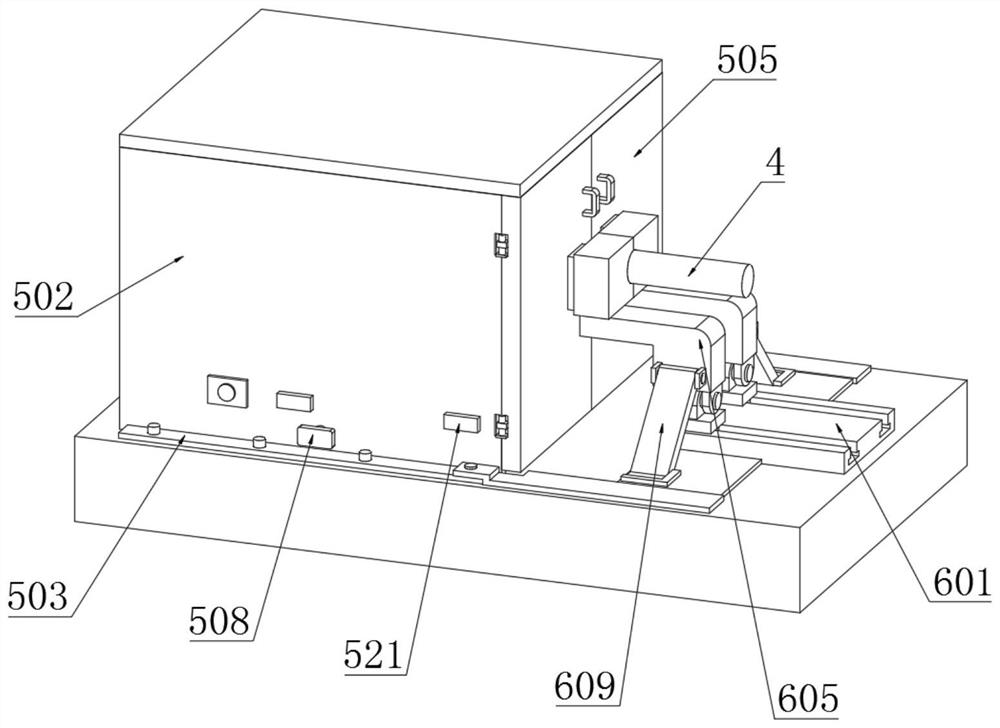

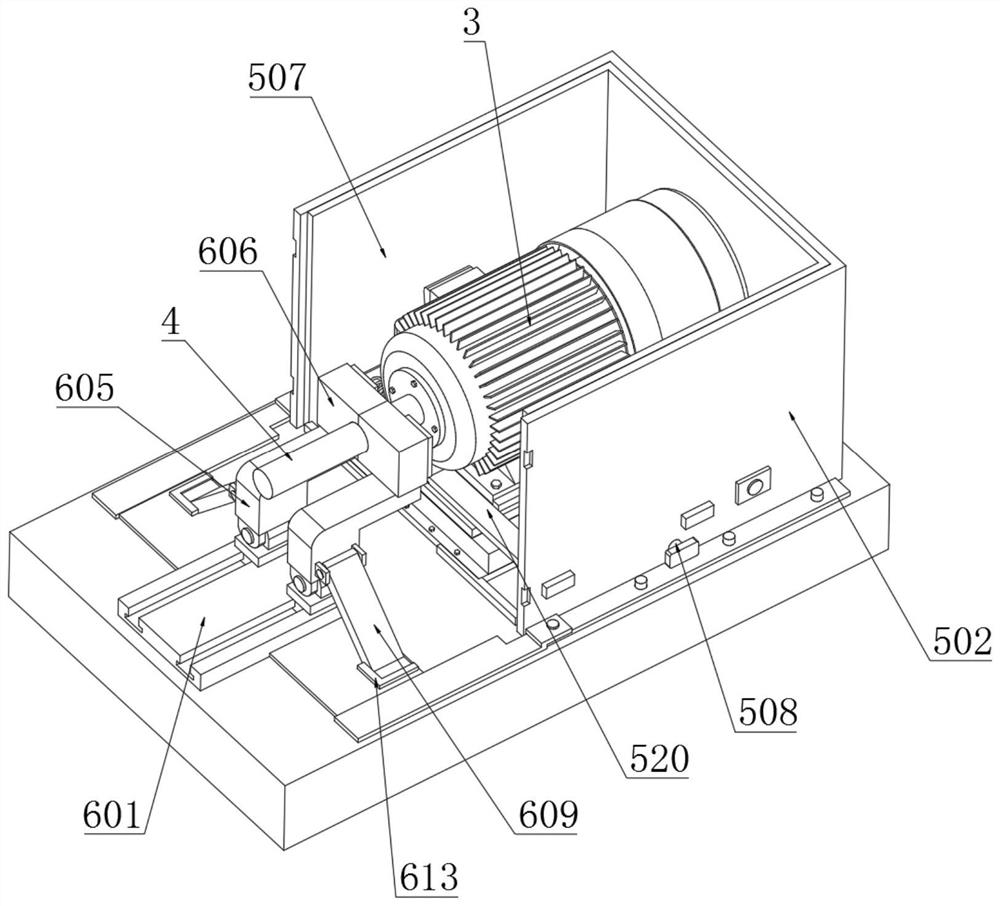

[0039] Example: as Figure 1-10 As shown, the present invention provides a technical solution, a power motor for preventing vibration, including a foundation 1, a shock-proof mechanism 2 is fixedly installed on the top of the foundation 1, and the shock-absorbing spring 205 and the buffer washer 208 will absorb the vibration generated when the motor 3 is running. The vibration keeps the motor 3 stable;

[0040] Mounting anti-vibration mechanism 2 includes mounting seat 201, mounting bolt 202, hollow groove 203, fixing sleeve 204, shock-absorbing spring 205, fixing ring 206, placing block 207, buffer washer 208, threaded hole 209, groove 210, extrusion The screw 211, the circular clamping block 212 and the limit strip 213;

[0041] A mounting seat 201 is fixedly installed in the middle of the top of the foundation 1, and mounting bolts 202 are fixedly installed at the bottom of both sides of the mounting seat 201 at equal distances. A hollow slot 203 is opened in the middle of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com