Quantum dot micro laser and preparation method thereof

A micro-laser and quantum dot technology, applied in lasers, phonon exciters, laser parts and other directions, can solve the problems of insufficient surface smoothness of micro-cavity structures, low luminous efficiency of quantum dots, and large laser loss, etc., and achieve processing accuracy. High, improve luminous efficiency, reduce the effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] BRIEF DESCRIPTION further aspect of the present invention in conjunction with the following:

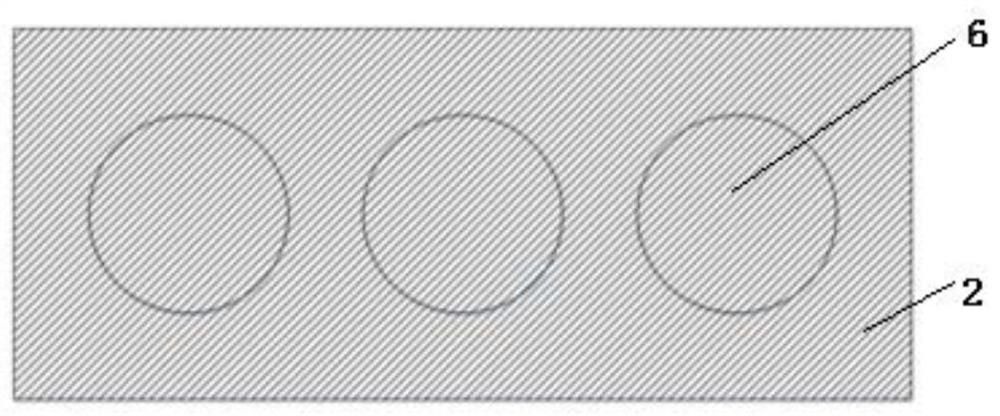

[0030] The present invention provides a micro quantum dot lasers, such as figure 1 , 2 As shown in the quantum dot laser micro SOI wafer to a silicon substrate as a carrier, a silicon disk using a suspension structure. Silicon disk suspension structure comprises a quantum dot laser micro silicon substrate layer disposed from bottom to top 1, a first silicon dioxide layer 2, a silicon dioxide layer 3 and the strut 4 silicon dioxide layer disc, round silica layer 4 on the surface of the disc is coated with a suspension 5, the quantum dot layer disposed on the quantum dot layer 5 has a plurality of quantum dots of different sizes, covered with the second silicon dioxide layer 6 on the quantum dot layer 5.

[0031] In an embodiment of the present invention, the suspension structure comprises a silicon disk 3 pillars silica layer 3, each silica support strut 3 a silicon dioxide layer d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com