Multi-layer resistance tape equal temperature rise calculation method

A calculation method, the technology of resistance band, applied in the field of temperature rise calculation, can solve the problems of brake resistance device disconnection, overheating of resistance band, cost increase, etc., and achieve the effects of stable resistance value, reduced volume, and reduced material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

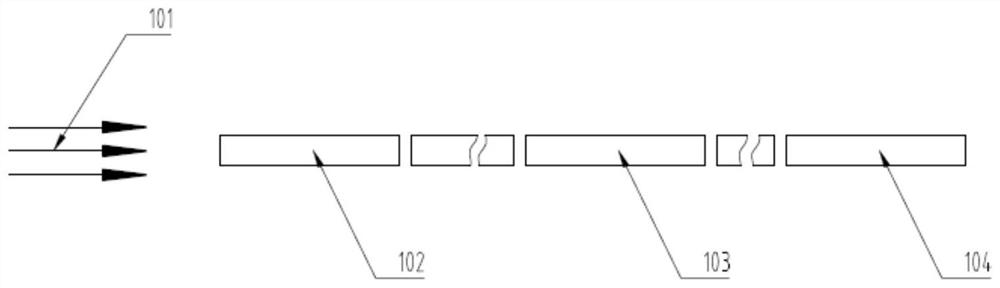

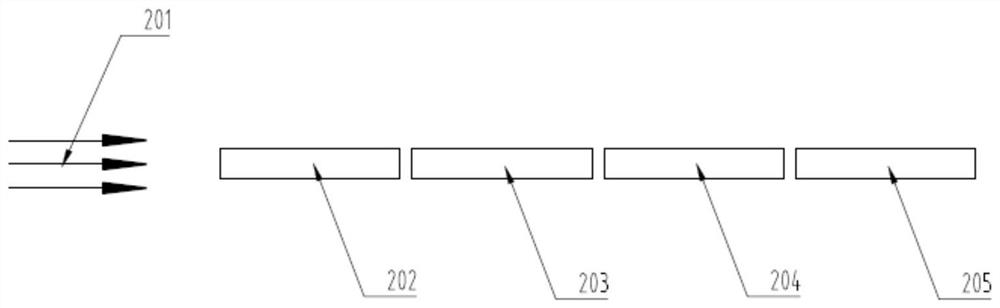

[0048] This embodiment discloses a calculation method for a braking resistor device, the structural diagram of which is shown in figure 2 . In this embodiment, four resistance strips of equal width are arranged in parallel along the flow direction of the cooling air 201: the first resistance strip 202 for the flow, the second resistance strip 203 for the flow, the third resistance strip 204 for the flow, and the resistance strip 204 for the flow. Flow 4th resistance strip 205 . It should be noted that the number of resistance bands in this embodiment is only a braking resistor device scheme using the calculation method of the present invention, and does not restrict the calculation method of the present invention. The number of resistance bands can be determined according to actual engineering needs. Adjustment.

[0049] In this example, the design input includes the total power .

[0050] In order to make the temperature rises of the 4 resistance bands in the present em...

Embodiment 2

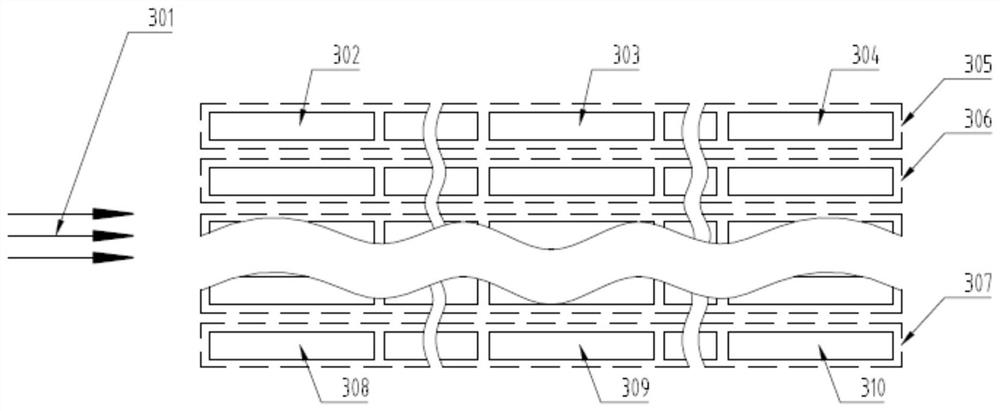

[0080] This embodiment discloses a calculation method for a braking resistor device, the structural diagram of which is shown in figure 2 . In this embodiment, it includes the first row of resistance strips 305 arranged in parallel along the flow direction of the cooling air 301, and the first row of resistance strips 305 includes N equal-width resistance strips: the first row meets the first resistance strip 302 ... the first row 1 row of resistance strips 303 facing the flow and the first row of resistance strips 304 facing the flow; in this embodiment, in addition to the resistance strips 305 of the first row, it also includes the second row arranged perpendicular to the flow direction of the cooling air 301 Row of resistance strips 306... Mth row of resistance strips 307: the Mth row of resistance strips 307 includes N equal-width resistance strips: the Mth row of resistance strips 308 ... the Mth row of resistance strips 308 ... the Mth row of resistance strips of i 309...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com