Light building curtain wall plate and preparation method thereof

A curtain wall panel, lightweight technology, applied in buildings, building components, building structures, etc., can solve the problems of polluting the environment, potential safety hazards, high weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a preparation method for the lightweight building curtain wall panel described in the above technical solution, comprising the following steps:

[0036] 1) Provide several flat plates;

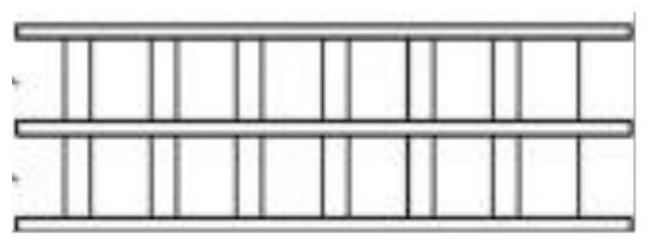

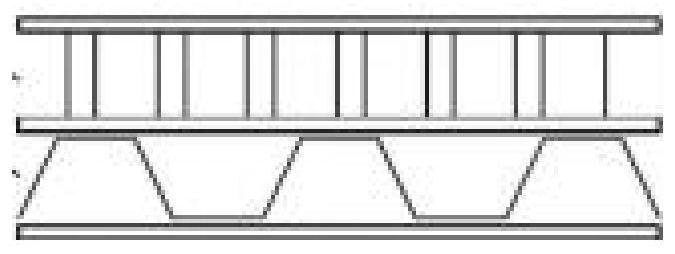

[0037] 2) Provide several hollow-structure plates; the number of the flat plates is one more than the number of hollow-structure plates;

[0038] 3) Alternately laminating the flat boards and hollow-structured boards, and applying an adhesive between adjacent boards, and then performing hot pressing to obtain a core layer;

[0039]4) a first surface layer is set on one side of the core layer, and a second surface layer is set on the other side of the core layer to obtain a lightweight building curtain wall panel;

[0040] Steps 1) and 2) are not limited in chronological order.

[0041] The present invention firstly provides several flat boards and several hollow-structured boards; the number of said flat boards is one more than the number of hollow-...

Embodiment 1

[0048] In this embodiment, a bamboo-wood composite honeycomb panel with a height of 10mm is used as a hollow structural panel, and as a lightweight layer unit, a bamboo flat panel with a thickness of 2.5mm is used as a base unit, and the first surface layer and the second surface layer are made of fluorocarbon paint. membrane;

[0049] Lay two bamboo-exposed panels and one bamboo-wood composite honeycomb panel in order from top to bottom: bamboo-exposed panels, bamboo-wood composite honeycomb panels, and bamboo-exposed panels, and coat phenolic resin between adjacent two-layer panels Adhesive, the dosage of phenolic resin adhesive is 260g / m 2 , to obtain the core layer blank, and then hot press the core layer blank at a temperature of 150° C. and a pressure of 1.5 MPa for 1 min to obtain a core layer;

[0050] After the two surfaces of the core layer are subjected to surface sanding, edge grinding, edge sealing and waterproof coating in sequence, the two surfaces of the core ...

Embodiment 2

[0052] This embodiment adopts the bamboo-wood composite honeycomb panel with a height of 10mm as the hollow structural plate, and the bamboo tube rotary-cut board with a thickness of 1.2mm is used as the base unit, and the first surface layer and the second surface layer adopt a coated ceramic coating film; wherein the bamboo tube rotary The cutting board is prepared by the following steps: cutting the bamboo into a veneer to obtain a thin bamboo with a thickness of 0.6mm; mixing and stirring the thermal elastomer of the model G140D and the isocyanate adhesive to obtain a binder; the isocyanate adhesive Account for 15% of the total mass of the binding material; the binding material is coated on the micro-thin bamboo surface, wherein the coating quality of the binding material is 0.6 times of the quality of the thin bamboo, and another piece of micro-thin bamboo is coated with the micro-thin bamboo of the binding material. After the bamboo is laminated, it is hot-pressed for 2 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com