Automatic cleaning system for sluice sludge for water conservancy project

A technology for automatic cleaning and water conservancy engineering, which is applied in water conservancy engineering, water/sludge/sewage treatment, sea area engineering, etc. Timely and appropriate treatment of water volume and silt, and the effect of reducing the difficulty of transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

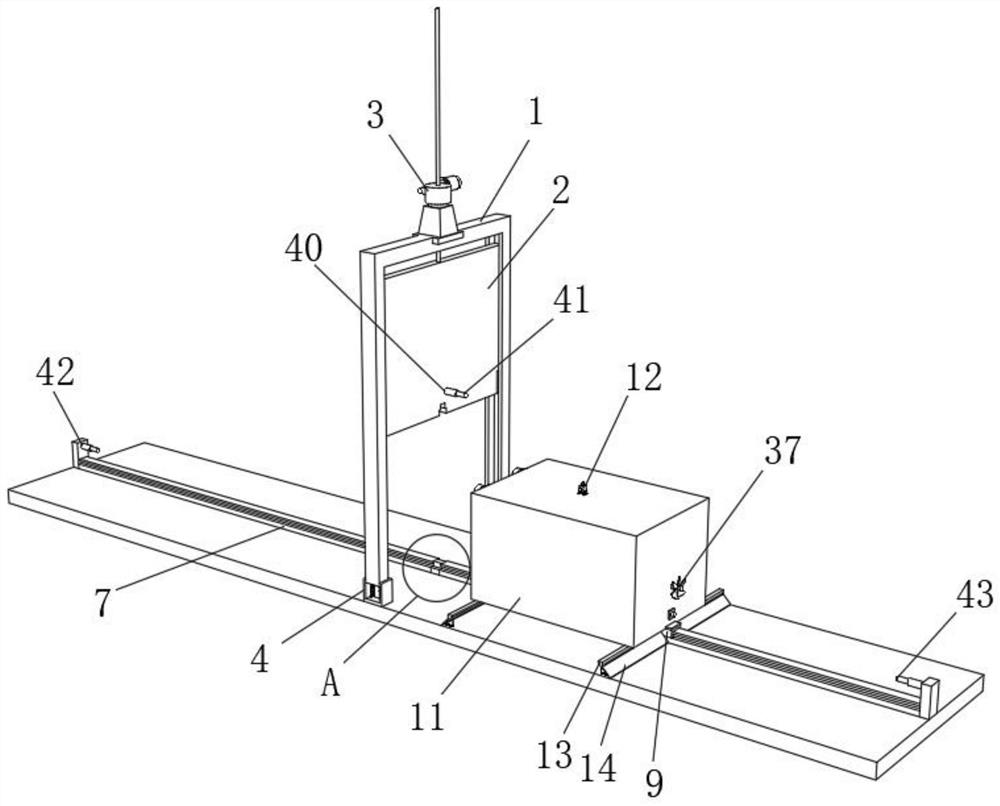

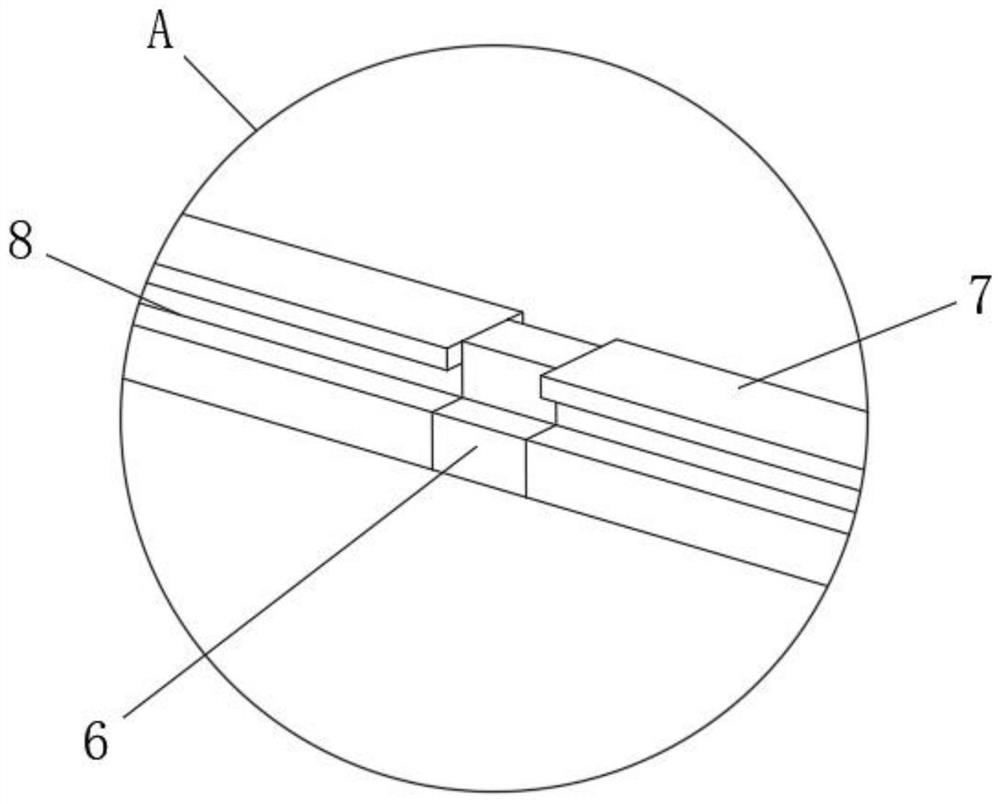

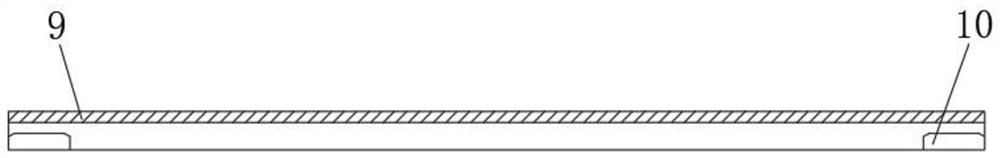

[0032] Such as Figure 1-9As shown, the embodiment of the present invention provides an automatic gateway sludge cleaning system for water conservancy projects, including a frame body 1 and a connecting block 6, the inner side of the frame body 1 is slidably connected to a gate 2, and the top of the frame body 1 is fixedly connected to a screw hoist 3. A movable block 4 is slidably connected to the bottom of the front and rear ends of the frame body 1, and two first springs 5 are fixedly connected to the inner bottom of the movable block 4, and guide rails 7 are fixedly connected to the left and right ends of the connecting block 6, and the front and rear sides of the guide rail 7 Both ends are provided with a strip groove 8, the outside of the guide rail 7 is provided with a slide rail 9, the left and right ends of the inside of the slide rail 9 are fixedly connected with a slider 10 corresponding to the strip groove 8, and the top of the slide rail 9 is fixedly connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com