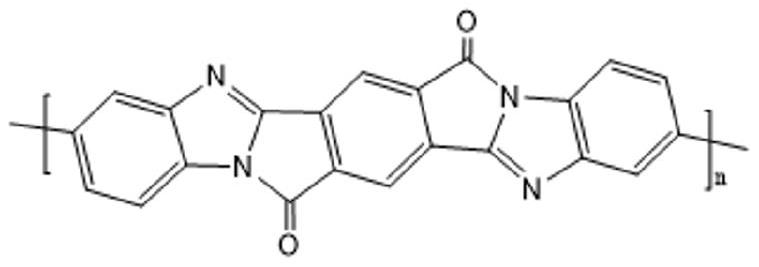

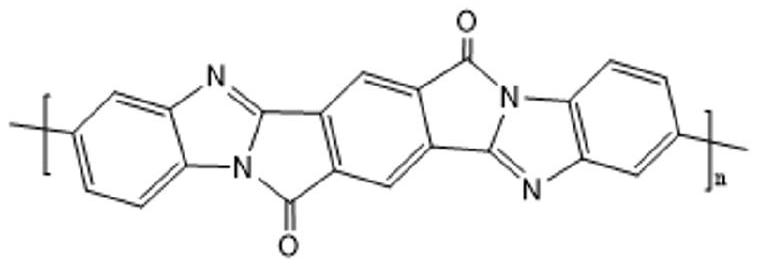

High-strength and high-modulus electrospun polypyrrolone nanofiber and preparation method thereof

A nanofiber, high-strength and high-modulus technology, applied in the fields of fiber chemical characteristics, textiles and papermaking, single-component synthetic polymer rayon, etc., can solve problems such as processability limitations, high boiling point, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A second aspect of the present invention provides a method for preparing the above-mentioned high-strength and high-modulus electrospun polypyrrole nanofibers, which includes the following steps:

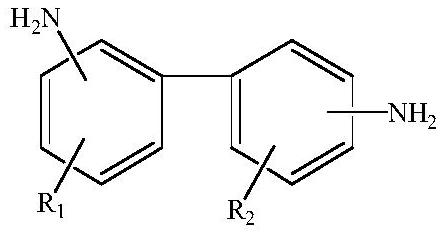

[0035] (1) Preparation of raw material monomers: acetic anhydride is dissolved in organic solvent A to obtain reaction material A, then the reaction material A is added to the organic solvent B solution of substituted benzphenyl diamine, and the temperature is not higher than 5 Reacting at a reaction temperature of °C for 2 to 6 hours to obtain an intermediate crude product; adding calcium oxide precipitation to the intermediate crude product, filtering, and concentrating to obtain a crude product; then recrystallizing the crude product to obtain the raw material monomer;

[0036] (2) Synthesis of the intermediate polyacetamidoamic acid: adding the raw material monomers into the reactor to perform condensation reaction with the dibasic acid anhydride in a solvent to obtain a p...

Embodiment 1

[0055] (1) 10 grams (46.67mmol) of 3,3'-diaminobenzidine is placed in the reactor, and 56.7 grams of THF is added to dissolve and prepare a solution with a concentration of 15%, and then in the above-mentioned 3,3'-diaminobenzidine (M=214.27) THF solution 95.29 grams (2*46.67mmol acetic anhydride (M=102.09), weight 9.53 grams) of 10% acetic anhydride THF solution is added dropwise at the speed of 1-3g / min, controls reaction temperature at React in the range of -5 to 0°C for 4 hours, then add 2.26g (46.67mmol) of dry calcium oxide (M=56.077), react with acetic acid to form calcium acetate precipitate, and precipitate from the THF solution; filter to remove calcium acetate in the system, And the filtrate was concentrated by rotary evaporation to obtain 13.6 grams of crude product (theoretical yield was 13.92 grams) of 3,3'-diamino-4,4'-diacetamidobiphenyl (M=298.27); Add ethanol / THF solvent with a volume ratio of 1 / 1 to the crude product of diamino-4,4'-diacetylaminobiphenyl, an...

Embodiment 2

[0060](1) 10 grams (46.67mmol) of 3,3'-diaminobenzidine is placed in the reactor, and 56.7 grams of THF is added to dissolve and prepare a solution with a concentration of 15%, and then in the above-mentioned 3,3'-diaminobenzidine (M=214.27) THF solution 95.29 grams (2*46.67mmol acetic anhydride (M=102.09), weight 9.53 grams) of 10% acetic anhydride THF solution is added dropwise at the speed of 1-3g / min, controls reaction temperature at React in the range of -5 to 0°C for 4 hours, then add 2.26g (46.67mmol) of dry calcium oxide (M=56.077), react with acetic acid to form calcium acetate precipitate, and precipitate from the THF solution; filter to remove calcium acetate in the system, And the filtrate was concentrated by rotary evaporation to obtain 13.6 grams of crude product (theoretical yield was 13.92 grams) of 3,3'-diamino-4,4'-diacetamidobiphenyl (M=298.27); Add ethanol / THF solvent with a volume ratio of 1 / 1 to the crude product of diamino-4,4'-diacetylaminobiphenyl, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com