Water washing stone and processing method for water washing stone

A processing method and water stone technology, which is applied in the processing of washing stones and the field of washing stones, can solve the problems of low reuse rate, large amount of waste residue in washing plants, fast wear of volcanic stones, etc., and achieve reduced processing costs, excellent environmental protection characteristics, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

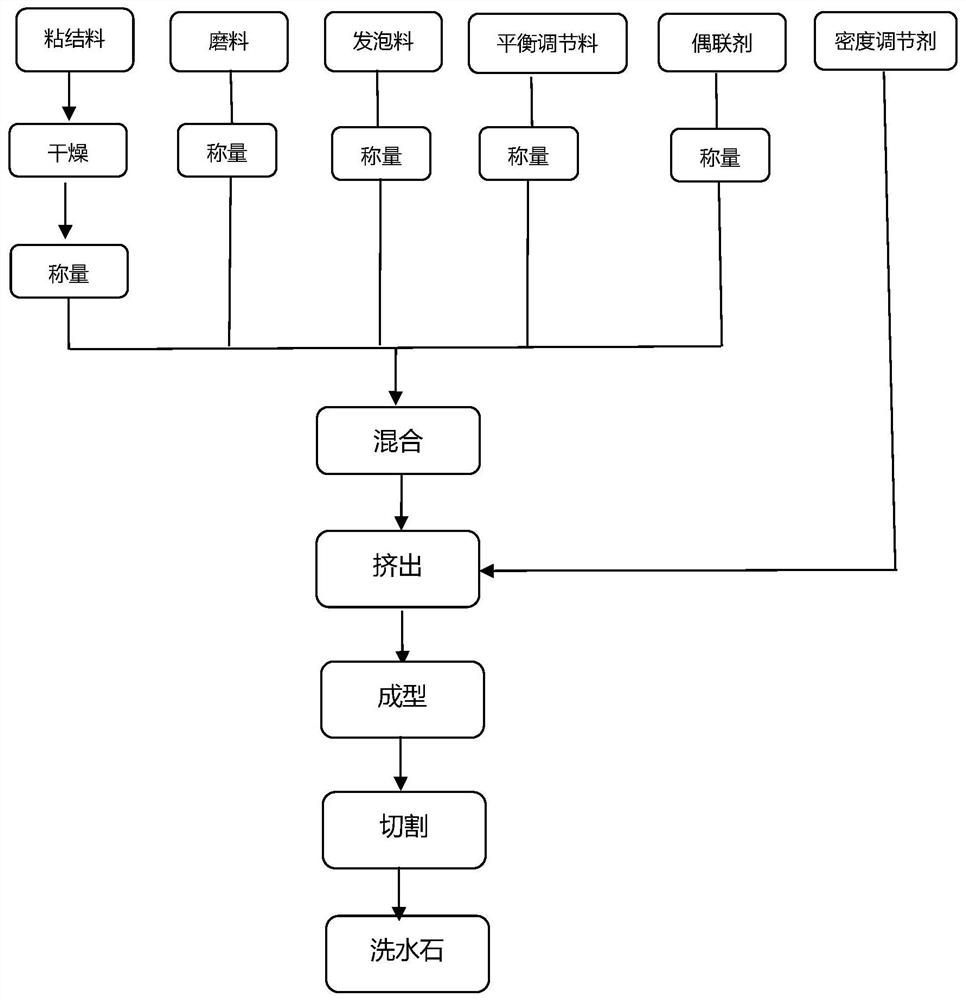

[0054]The washing stone of the invention is made by mixing and extruding binder, abrasive, foaming material, balance adjusting material, density adjusting agent and coupling agent.

[0055] Prepared in parts by weight, the binder is 45 parts, the abrasive is 30 parts, the foaming material is 7 parts, and the balance adjusting material is 5 parts.

[0056] The binder is prepared in parts by weight, and the binder includes 10 parts of granular modified ASA plastic, 7 parts of granular modified PP plastic, 30 parts of granular modified AS plastic, granular modified 25 parts of non-toxic PBT plastics, 15 parts of granular modified PA plastics, and 13 parts of granular modified PC plastics. The granular modified plastics are weighed according to the determined parts by weight, and mixed evenly with a mixer. The binder is extruded and granulated by an extruder, and the melt index of the binder is 1.0-1.8 g / min.

[0057] Through above-mentioned invention and through test data show, ...

Embodiment 2

[0072] The washing stone of the invention is made by mixing and extruding binder, abrasive, foaming material, balance adjusting material, density adjusting agent and coupling agent.

[0073] Prepared in parts by weight, the binder is 45 parts, the abrasive is 30 parts, the foaming material is 8 parts, and the balance adjusting material is 5 parts.

[0074] The binder is prepared in parts by weight, and the binder includes 10 parts of granular modified ASA plastic, 5 parts of granular modified PP plastic, 35 parts of granular modified AS plastic, granular modified 27 parts of non-toxic PBT plastics, 10 parts of granular modified PA plastics, and 13 parts of granular modified PC plastics. The granular modified plastics are weighed according to the determined parts by weight, and mixed evenly with a mixer. The binder is extruded and granulated by an extruder, and the melt index of the binder is 1.0-1.8 g / min.

[0075] Through the above invention and through test data, the washin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com