Tire friction reduction and damage reduction equipment

A tire and equipment technology, applied in the field of tire wear and loss reduction, can solve the problems of tire high temperature wear, long driving time, high tire surface temperature, etc., and achieve the effects of not being easily worn, alleviating delamination and bursting, and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

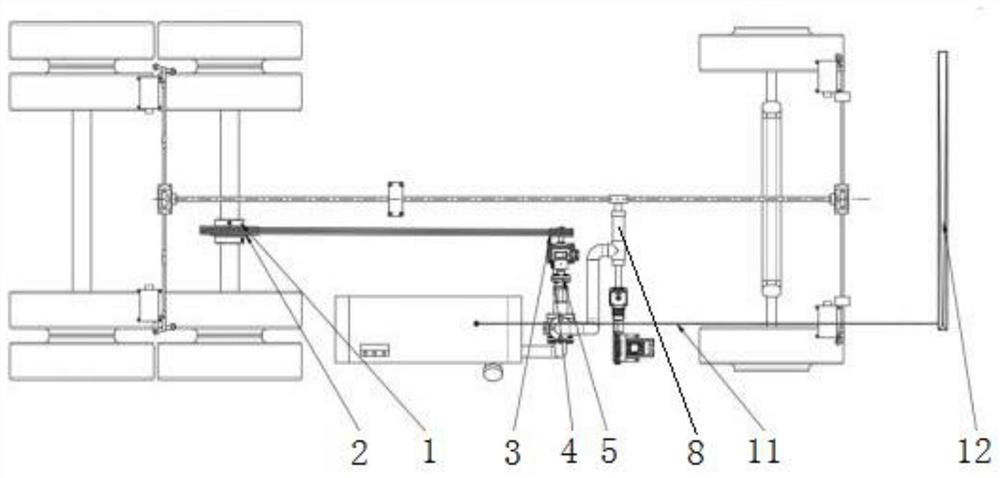

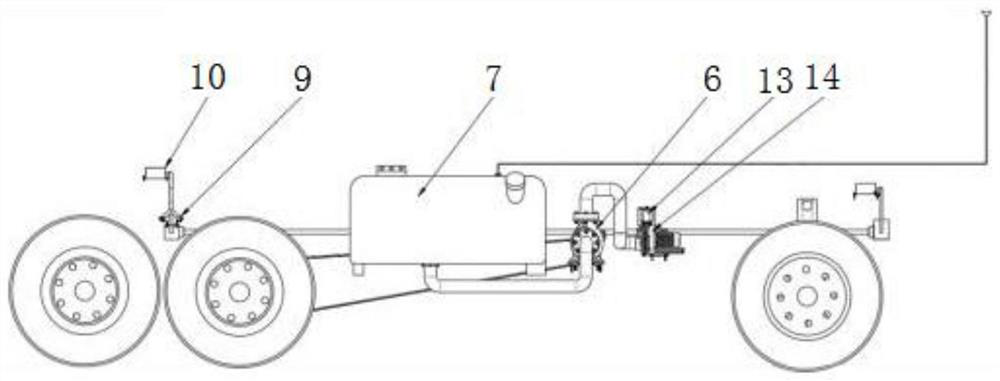

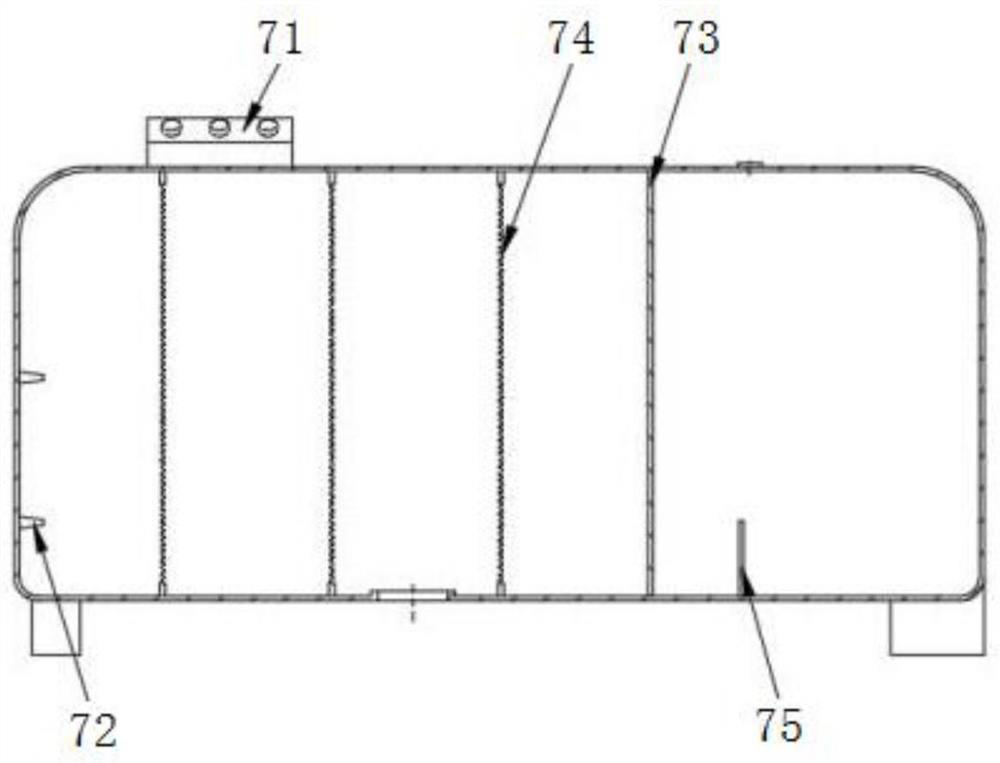

[0031] The main structure of the tire friction and loss reduction equipment involved in this embodiment includes a large pulley 1, a V-belt 2, a small pulley 3, a transmission 4, a coupling 5, a water pump 6, a water tank 7, a main pipeline 8, and an atomizing nozzle 9 , buffer pressurization mechanism 10, collection pipe 11, rainwater collection tank 12, electromagnetic valve 13 and air pump 14; large pulley 1 is connected with small pulley 3 through V-belt 2, and small pulley 3 passes speed changer 4 and shaft coupling 5 Connect with the water pump 6, the water inlet pipe of the water pump 6 is connected with the water tank 7, the water outlet pipe of the water pump 6 is connected with the main pipe 8, the main pipe 8 extends to the front and rear tires, the end is provided with an atomizing nozzle 9, and the atomizing nozzle 9 is provided with There is a buffer pressurization mechanism 10; the water tank 7 is connected to the rainwater collection tank 12 through the collecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com