Automatic feeding thread rolling mechanism

An automatic feeding and threading technology, applied in the field of thread processing, can solve the problems of low quality of workers' working environment, high risk factor of workers, and exposure to the outside, so as to avoid contact with metal debris and dust, the process is coherent and simple, and the work efficiency is improved. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

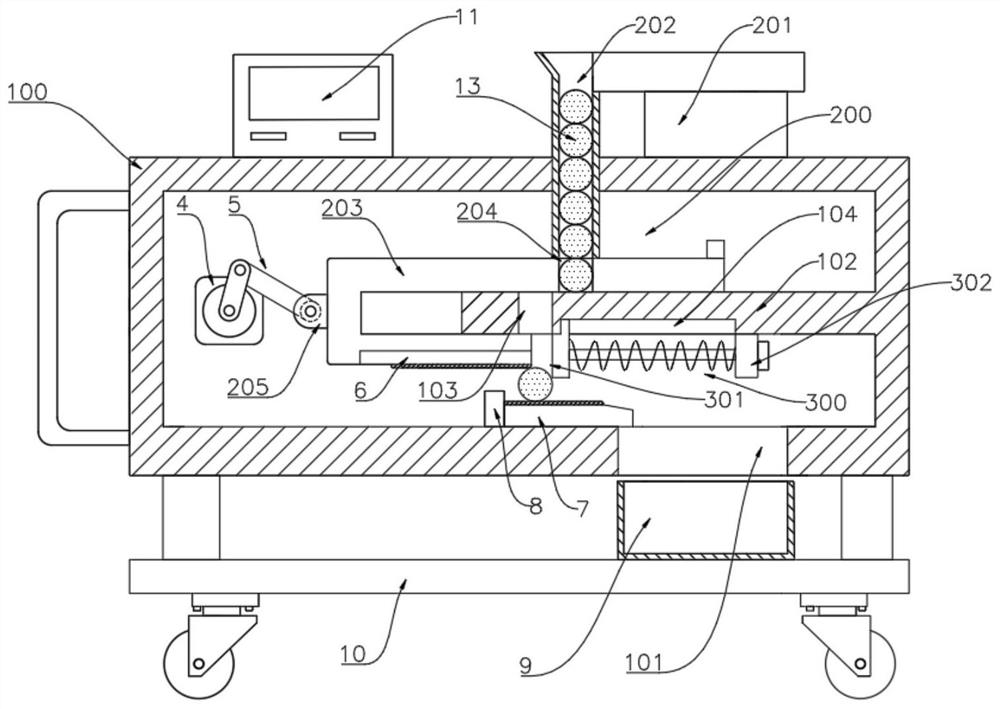

[0021] A thread rolling mechanism for automatic feeding, comprising a base 10, an automatic feeding device 200 and an auxiliary processing device 300, a housing 100 is fixedly installed on the top of the base 10, a vertical feeding conduit 202 is fixed on the top of the housing 100, the housing A horizontal guide plate 102 is fixed on the inner wall on the right side of 100 , the left end of the guide plate 102 is provided with a lower feeding port 103 , and the bottom of the guide plate 102 is provided with a slide rail 104 .

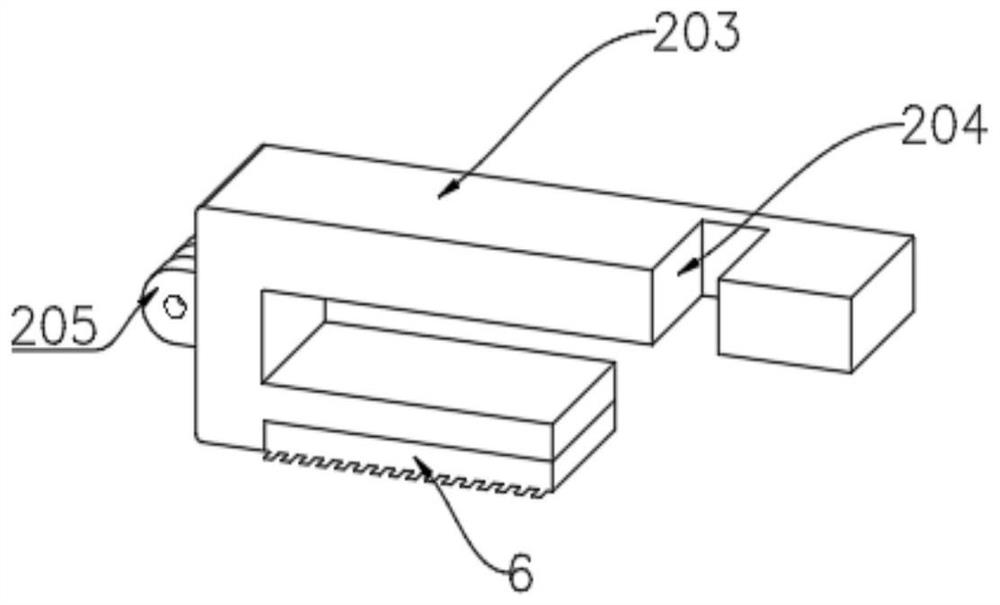

[0022] In this embodiment, the automatic feeding device 200 includes a control bracket 203 that is slidably fitted on the guide plate 102. The left side of the control bracket 203 has a connecting seat 205. The rear inner wall of the housing 100 is fixedly mounted with a motor 4. One end of the folding mechanism 5 is fixedly connected to the output end, and the other end of the folding mechanism 5 is rotatably connected to the connecting seat 205. The c...

Embodiment 2

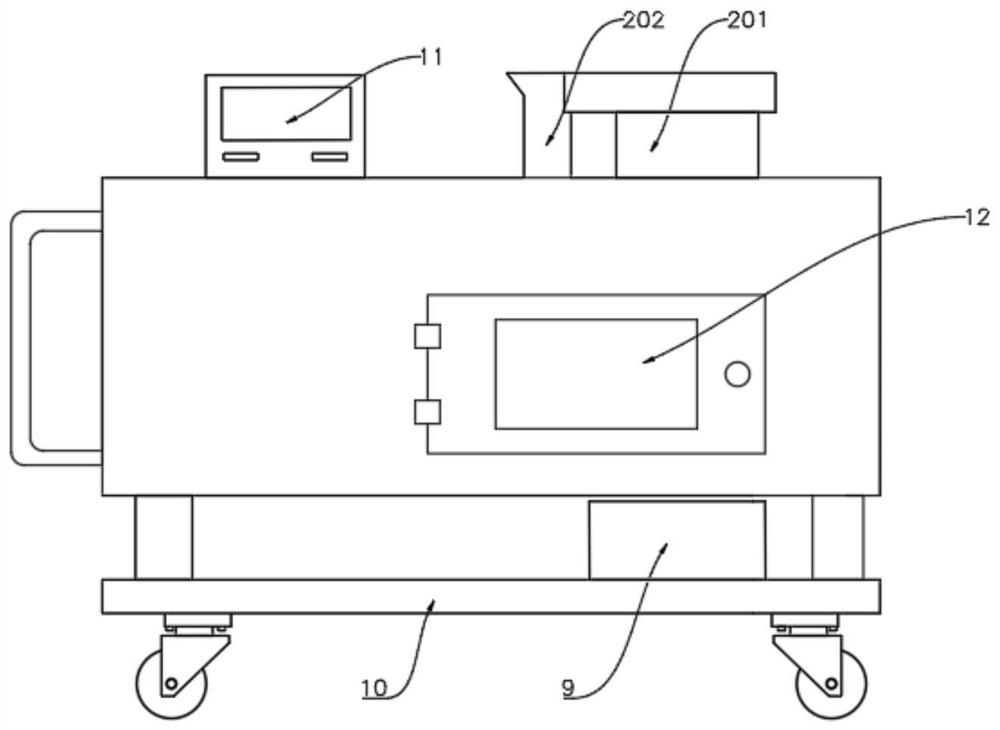

[0024] A thread rolling mechanism for automatic feeding. On the basis of Embodiment 1, the thickness of the upper horizontal plate of the control bracket 203 is equal to the diameter of the workpiece 13 to be processed, and the distance between the moving washboard 6 and the lower horizontal plate of the control bracket 203 is Connect with bolts, the fixed washboard 7 is connected with the bottom of the inner wall of the housing 100 with bolts, the guide plate 102 is slidingly fitted between the upper and lower horizontal plates, the bottom of the housing 100 is provided with a discharge port 101, and the base 10 is equipped with a The receiving container 9 relative to the discharge port 101, the bottom four corners of the base 10 are equipped with universal wheels, the left side of the housing 100 is fixedly equipped with a handle, and the front of the housing 100 is provided with a transparent glass observation window 12.

[0025] In this embodiment, a controller 11 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com