Flotation separation method for bastnaesite and barite

A bastnasite and separation method technology, applied in flotation, solid separation and other directions, can solve the problems of hindering flotation separation, large dosage of chemicals, and high production costs, and achieve enhanced inhibition effect, enhanced action site, and improved recovery. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

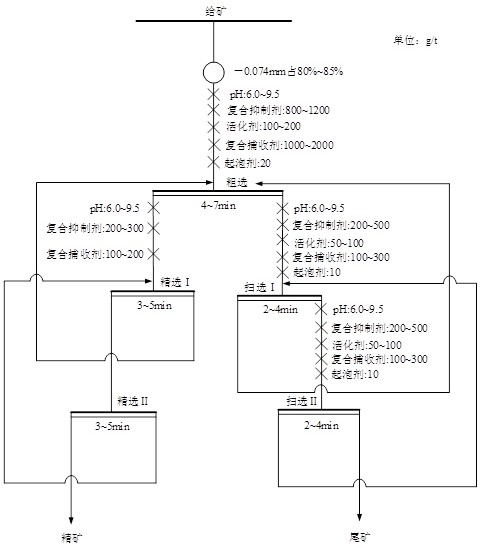

Image

Examples

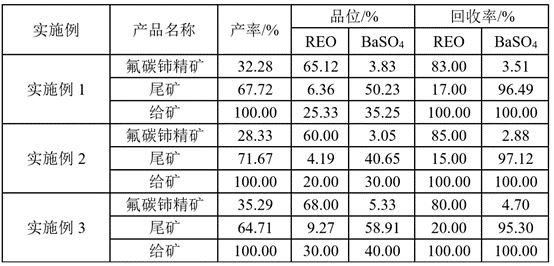

Embodiment 1

[0030] In this example, the bastnaesium-type rare earth ore flotation ore from a rare earth dressing plant in Sichuan is used as the selected raw ore. Its REO content is 25.33%, barite content is 35.25%, and it also contains a small amount of gangue such as quartz, fluorite, and calcite. mineral.

[0031] The flotation separation method of bastnaesite and barite described in the present embodiment specifically comprises the following steps:

[0032] (1) Weigh 500g of selected raw ore for grinding, process the ore fineness to -0.074mm, accounting for 80%, transfer the mineral raw materials to the flotation tank, and adjust the pulp concentration to 35%.

[0033] (2) During the flotation process, first adjust the pH value of the pulp to 6.0, add a compound inhibitor of 1000g / t (the mass ratio of polyaluminum chloride to water glass is 4:1), act for 5 minutes, and then add the activator lead nitrate 150g / t, act for 4 minutes, then add composite collector 1600g / t (the mass ratio ...

Embodiment 2

[0038]Mineral raw materials in this embodiment: use bastnaesium type rare earth ore flotation ore from a rare earth dressing plant in Sichuan as the selected raw ore, with REO content of 20%, barite content of 30%, and a small amount of quartz, fluorite and calcite and other gangue minerals.

[0039] The flotation separation method of bastnaesite and barite described in the present embodiment specifically comprises the following steps:

[0040] (1) Weigh 500g of raw ore, and process the ore fineness to -0.074mm, accounting for 85%; transfer the mineral raw materials to the flotation tank, and adjust the concentration of the ore pulp to 40%;

[0041] (2) During the flotation process, first adjust the pH value of the pulp to 8.5, add 800g / t of composite inhibitor (the mass ratio of polyaluminum ferric chloride to water glass is 7:1), act for 4 minutes, and then add activator nitric acid Lead 100g / t, act for 3 minutes, then add composite collector 1000g / t (the mass ratio of sali...

Embodiment 3

[0046] Mineral raw materials in this embodiment: use bastnaesium type rare earth ore flotation ore from a rare earth dressing plant in Sichuan as raw ore, with REO content of 30%, barite content of 40%, and a small amount of quartz, fluorite and calcite and other gangue minerals.

[0047] The flotation separation method of bastnaesite and barite described in the present embodiment specifically comprises the following steps:

[0048] (1) Weigh 500g of raw ore, and process the fineness of the ore to -0.074mm, accounting for 83%; transfer the mineral raw materials to the flotation tank, and adjust the concentration of the ore pulp to 30%.

[0049] (2) During the flotation process, first adjust the pH value of the slurry to 9.5, add 1200g / t of composite inhibitor (the mass ratio of polyaluminum iron silicate to water glass is 8:1), act for 5 minutes, and then add activator nitric acid Lead 200g / t, act for 4 minutes, then add composite collector 2000g / t (the mass ratio of salicyli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com