Semiconductor structure and forming method of semiconductor structure

A technology of semiconductor and isolation structure, applied in semiconductor devices, semiconductor/solid-state device manufacturing, nanotechnology for information processing, etc., can solve the problem that the performance of fork nanosheets needs to be improved, and achieve the effect of uniform thickness and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] As mentioned in the background art, the performance of the existing fork-shaped nanosheets still needs to be improved. Now analyze and illustrate in conjunction with specific embodiment.

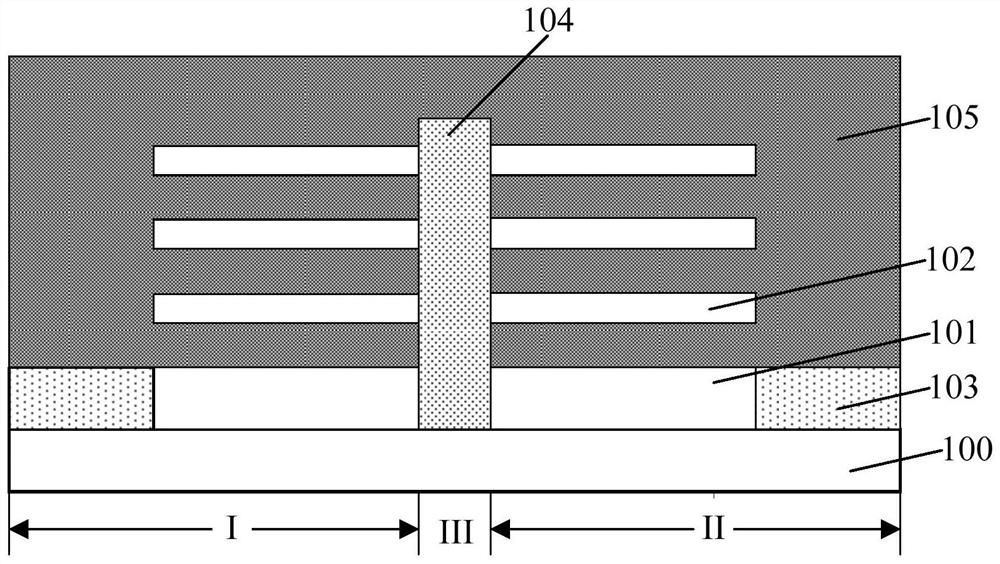

[0040] figure 1 It is a schematic cross-sectional structure diagram of a semiconductor structure in an embodiment.

[0041] Please refer to figure 1 , including: a substrate 100, the substrate 100 including a first region I, a second region II, and an isolation region III between the first region I and the second region II; The fin structure on the above, the fin structure includes the first nanowire 101 and several second nanowires 102 on the first nanowire 101; the isolation structure 104 on the isolation region III, the isolation structure 104 is respectively connected with The fin structures on the first region I and the second region II are in contact; the isolation layer 103 is located on the first region I and the second region II, and the isolation layer 103 is located on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com