While-drilling sound wave well cementation quality evaluation method and processing device

A quality evaluation and filtering technology, applied in construction and other directions, can solve the problems of high cost and long time, and achieve the effect of good effect, comprehensive cementing quality, and shortening logging time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

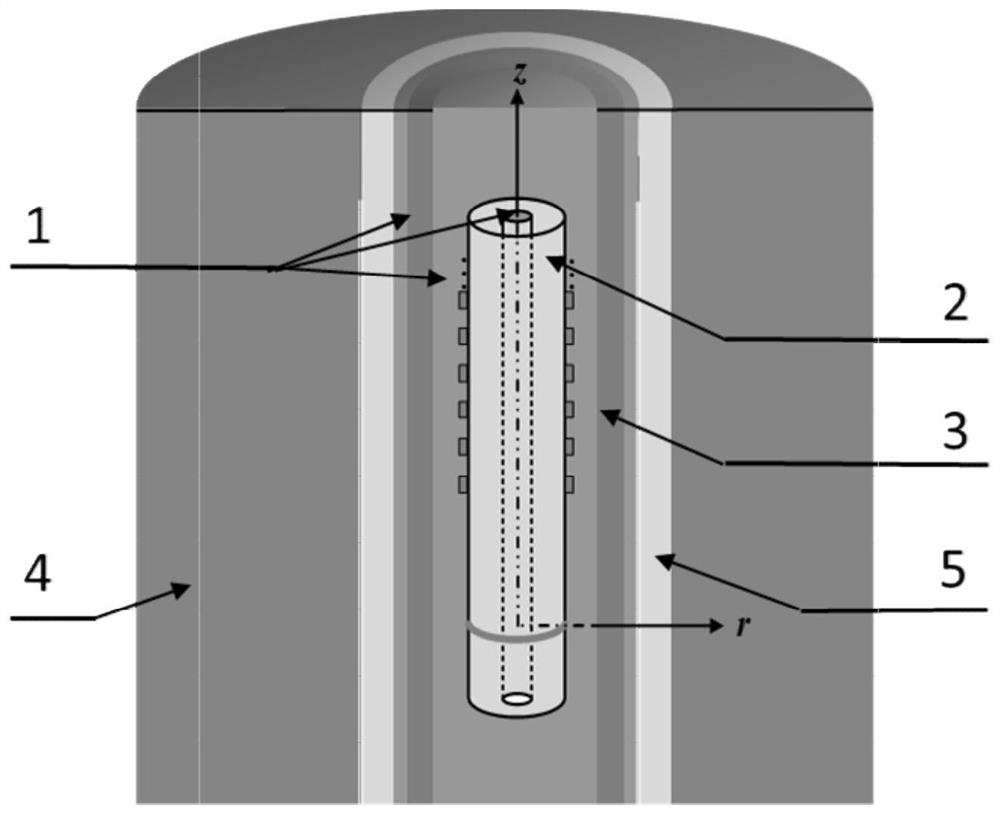

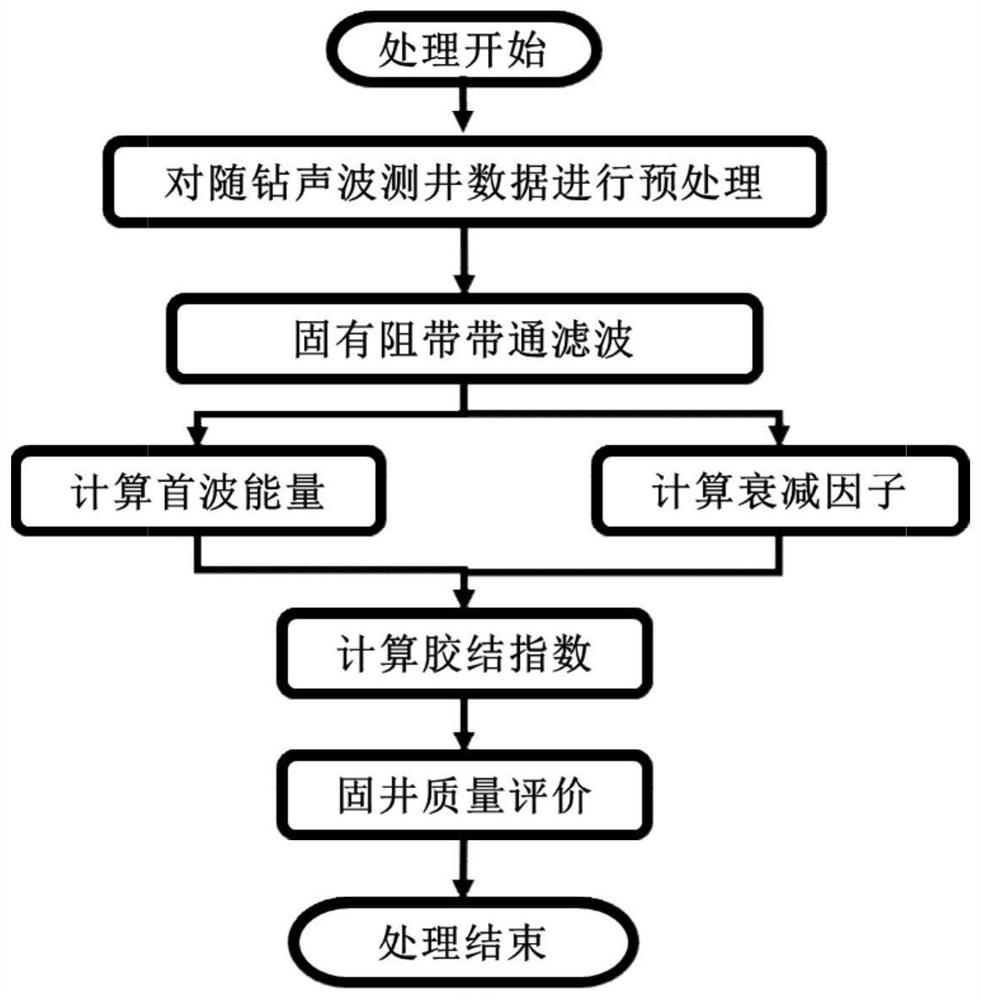

[0050] Such as figure 1 , 2 As shown, the present invention proposes a method for evaluating cementing quality by acoustic waves while drilling, and the working process is as follows:

[0051] Step 1. Preprocess the data while drilling, restore the waveform curve, obtain the full wave train data of the acoustic wave while drilling, and perform filtering processing according to the requirements, that is, remove the low-frequency and high-frequency logging noise in the wave train;

[0052] Step 2. According to the inherent stop band of the tool while drilling, for example Figure 4-a is the inherent stop band of a logging-while-drilling tool, and this frequency range is used for band-pass filtering, Figure 4-b From top to bottom are the LWD waveforms before and after bandpass filtering. It can be seen that the drill collar wave in the first wave after filtering is suppressed, and the remaining part is mainly casing wave;

[0053] Step 3. Calculate the energy of the first wav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com