Corrugated paper compounding adhesive and preparation method thereof

A corrugated paper, uniform mixing technology, applied in the direction of adhesives, adhesive types, starch adhesives, etc., can solve the problems of slow drying speed of adhesives, high water content of corrugated paper, etc., to shorten drying time, enhance drying speed, and enhance adhesion combined strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

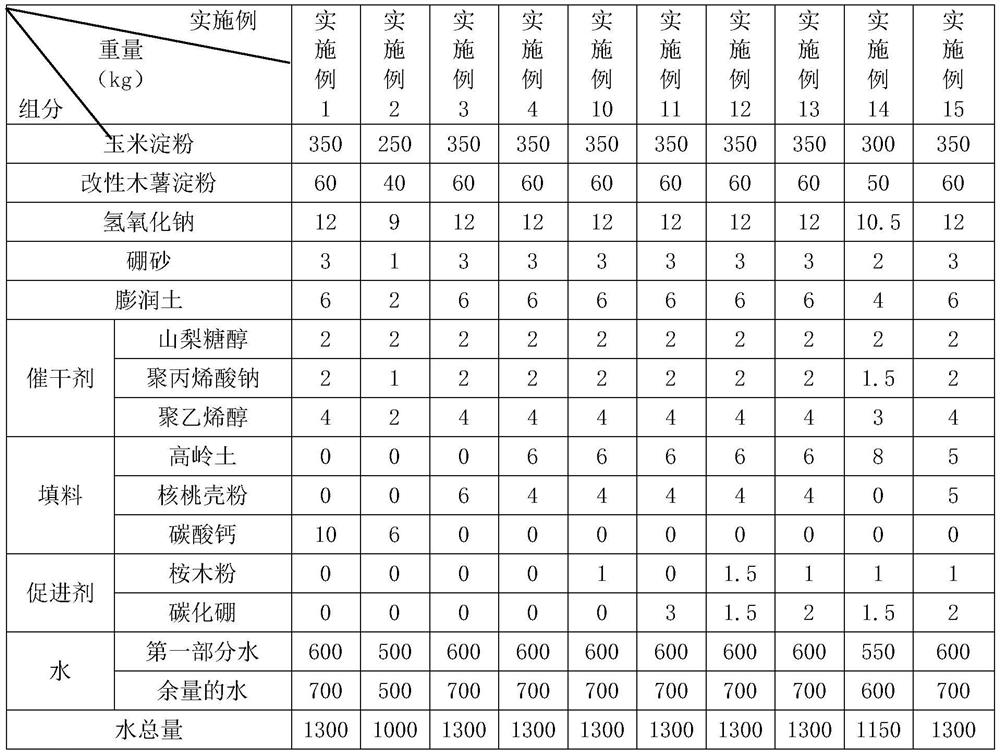

Examples

preparation example 1

[0048] Preparation example 1: a kind of modified tapioca starch, included concrete component and weight are as shown in table 2, comprise following preparation steps:

[0049] A1: Mix and stir tapioca starch and water, the stirring speed is 200r / min, after stirring evenly, add the nonionic surfactant fatty alcohol polyoxyethylene ether, mix and stir, the stirring speed is 200r / min, after stirring uniformly, obtain primary cassava starch;

[0050] A2: At a temperature of 75°C, mix and stir primary tapioca starch and acrylic resin at a stirring speed of 300r / min. After stirring evenly, add initiator and silane coupling agent, mix and stir evenly, and dry after 3 hours. After pulverizing, the modified tapioca starch is obtained.

preparation example 2

[0051] Preparation example 2: a kind of modified tapioca starch, and the difference of preparation example 1 is that included concrete component and weight are as shown in table 2, comprise following preparation steps:

[0052]A1: Mix and stir tapioca starch and water, the stirring speed is 200r / min, after stirring evenly, add the nonionic surfactant fatty alcohol polyoxyethylene ether, mix and stir, the stirring speed is 200r / min, after stirring uniformly, obtain primary cassava starch;

[0053] A2: At a temperature of 85°C, mix and stir the primary tapioca starch and polyacrylamide at a stirring speed of 300r / min. After stirring evenly, add the initiator and silane coupling agent. After mixing and stirring evenly, wait for 1 hour before drying After drying and crushing, the modified tapioca starch is obtained.

preparation example 3-4

[0054] Preparation example 3-4: a kind of modified tapioca starch, and the difference of preparation example 2 is that the weight of each component is different, and the concrete component that comprises and weight are as shown in table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com