Rectangular spring forming equipment

A forming equipment and a rectangular spring technology, applied in the field of rectangular spring forming equipment, can solve the problems of uneven fixing force of the rectangular spring, affecting the winding forming of the rectangular spring, and uneven force of the rectangular spring, so as to ensure the processing quality and prevent the Rebound deformation, the effect of avoiding rebound deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

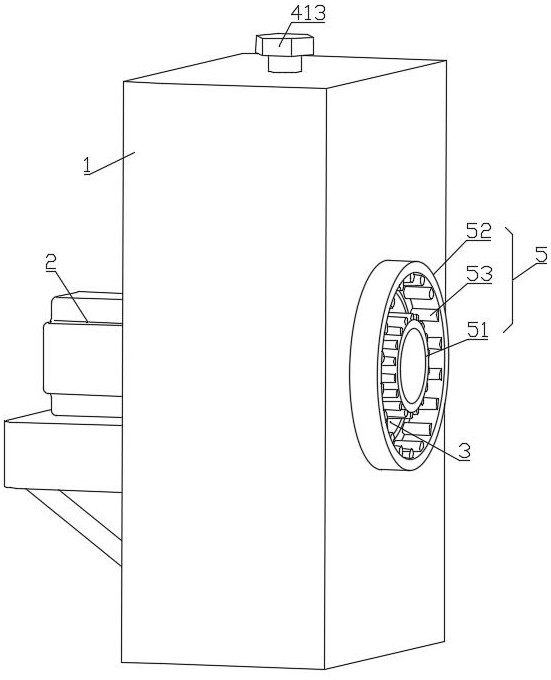

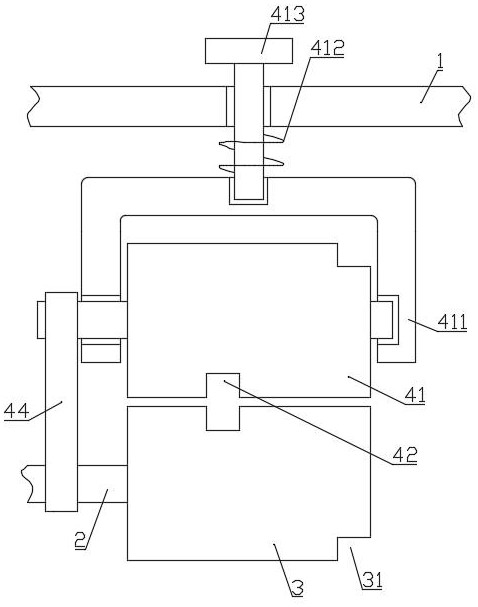

[0021] Refer Figure 1-4 , A rectangular spring forming apparatus, including the frame body 1, the frame body 1 is mounted, the drive motor 2 is attached to the drive motor 2, and the drive shaft 21 is fixedly connected, and the drive shaft 21 is fixedly connected to the shaped roller 3. The molding roller 3 is rotated within the frame body 1, and the outer peripheral side is opened, and the compression mechanism 4 is provided in the frame body 1, the wire feedstock is inserted into the shaped roller 3, and the drive motor 2 When the drive shaft 21 is rotated by the drive shaft 21, when the pressing mechanism 4 presses the steel wire end, the winding formation of the rectangular spring is completed.

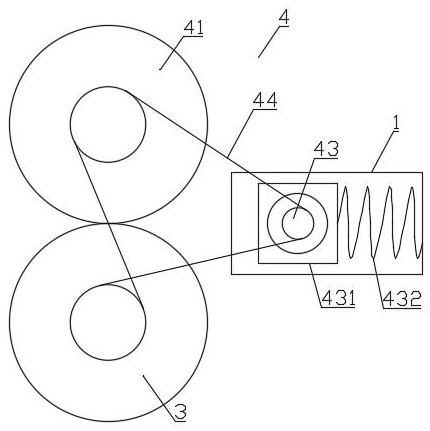

[0022] The compression mechanism 4 includes a pressing wheel 41, a helical spray groove 42, a tension wheel 43, and a drive toothed strip 44, and the pressing wheel 41 is rotated within the pressing frame 411, and the frame body 1 is opened in the vertical direction. Tank, wherein the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com