Coal and gangue separation system and identification method

A technology for coal gangue separation and coal gangue separation, applied in sorting and other directions, can solve the problems of high equipment cost, complex equipment and difficult maintenance, and achieve the effects of simple equipment, easy maintenance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

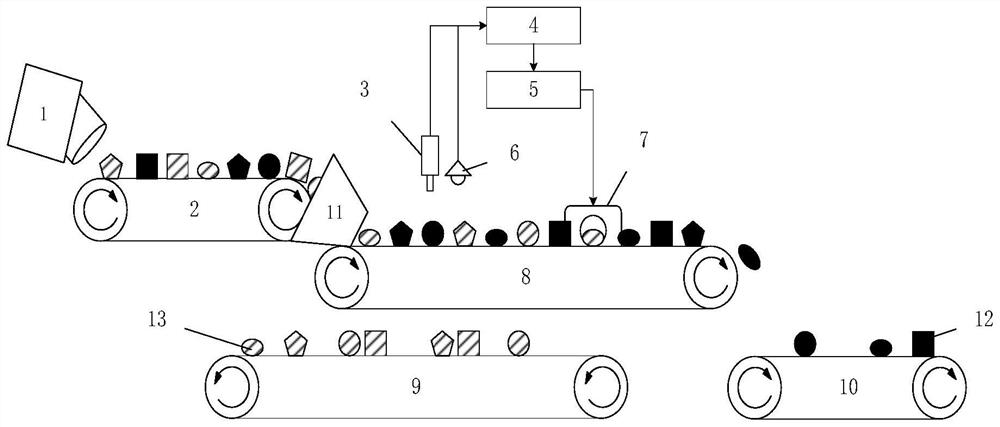

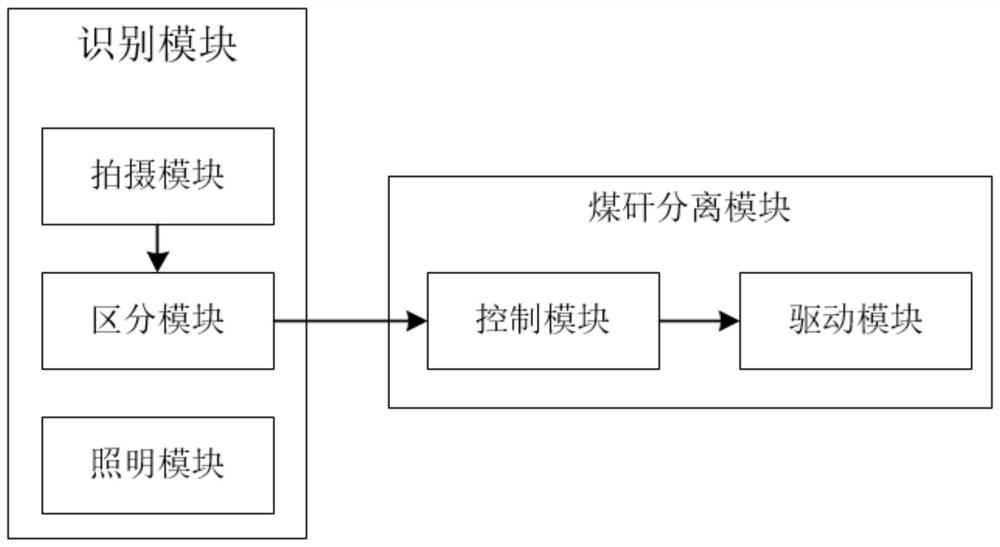

[0038] as attached figure 1 Shown: a coal and gangue sorting system, including a vibrating coal feeder 1, a main conveyor belt, an identification module, a coal and gangue separation device, a gangue returning conveyor belt 9 and a first coal conveyor belt 10:

[0039] The vibrating coal feeder 1 is located at the starting end of the main conveyor belt, and is used to transport the coal gangue mixture to the main conveyor belt, and the coal gangue includes coal 12 and gangue 13 .

[0040] The main conveyor belt is used to convey the coal gangue mixture; the main conveyor belt includes the first conveyor belt 2 and the gangue conveyor belt 8, and the vibrating coal feeder 1 is located at the starting end of the first conveyor belt 2 and the end of the first conveyor belt 2 Below is the starting end of gangue conveyor belt 8, the identification module is located above the starting end of gangue conveyor belt 8, and the coal and gangue separation device is located at one side of ...

Embodiment 2

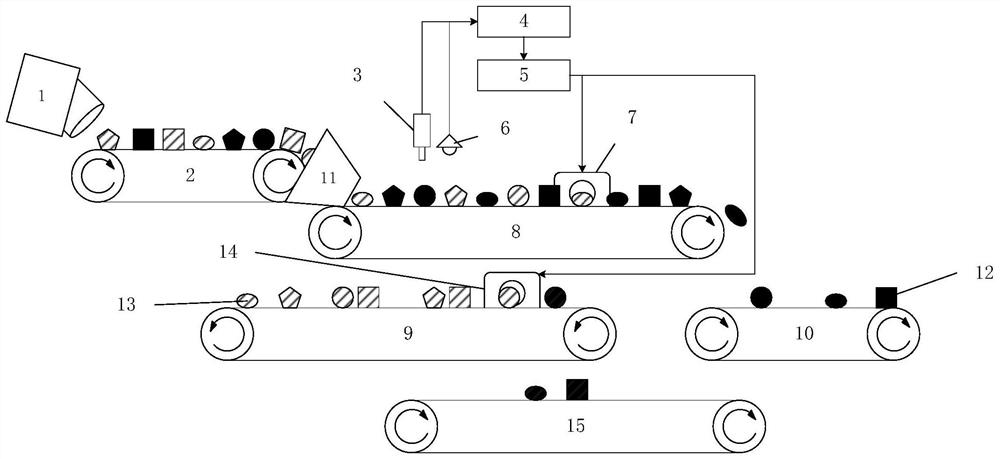

[0067] as attached image 3 As shown, the difference between this embodiment and Embodiment 1 is that in this embodiment, the lighting module 6 is a multi-color lighting lamp, and the control module 5 controls the color change of the lighting lamp according to the shooting frequency of the shooting module 3, so The photographing module 3 is also used to perform secondary photographing of the target object on the gangue conveyor belt 9 to obtain a secondary photographed image; the distinguishing module 4 is also used to put the secondary photographed image into the gangue 13 model for identification , to obtain the degree of confidence of the target object in the image; the second drive device 14 and the second coal conveyor belt 15 are also included in the present embodiment; the second drive device 14 is electrically connected with the control module 5, and the controller also uses In determining the target object whose confidence level is less than the set value in the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com