Self-cleaning biological medicine pelleting equipment

A biomedical and self-cleaning technology, applied in the field of biomedicine, can solve the problems of energy saving, troublesome, difficult to clean without water, etc., to reduce static electricity and improve cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

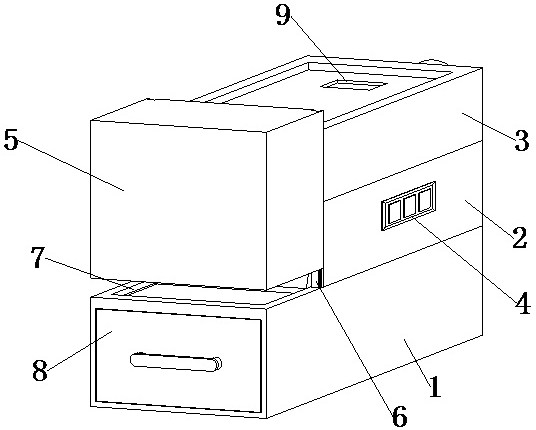

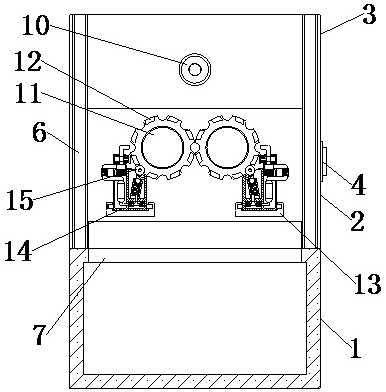

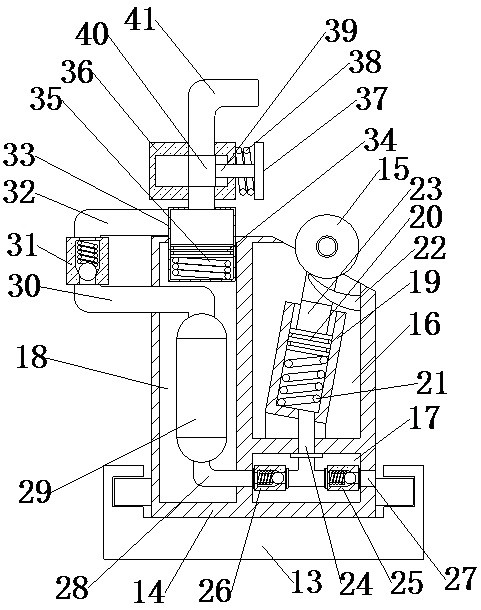

[0029] see Figure 1-Figure 5 , a self-cleaning biomedical pill making equipment, including a collection box 1, a motor box 2 and a screw conveying device 3, the motor box 2 is fixed on the rear side of the upper end of the collection box 1, and the screw conveying device 3 is fixed on the motor box 2 On the upper end, the left and right sides of the front end of the motor box 2 are rotatably connected with extruding cutter wheels 11, the upper end of the screw conveying device 3 is provided with a material inlet 9, and the front end of the screw conveying device 3 is provided with a discharge port 10, so Drive motors are installed on the left and right sides of the motor box 2, the drive end of the drive motor is connected to the extrusion cutter wheel 11, the discharge port 10 is located above the extrusion cutter wheels 11, and the motor box 2 The right part is equipped with a switch 4, through the switch 4, the screw conveying device 3 and the drive motor can be started, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com