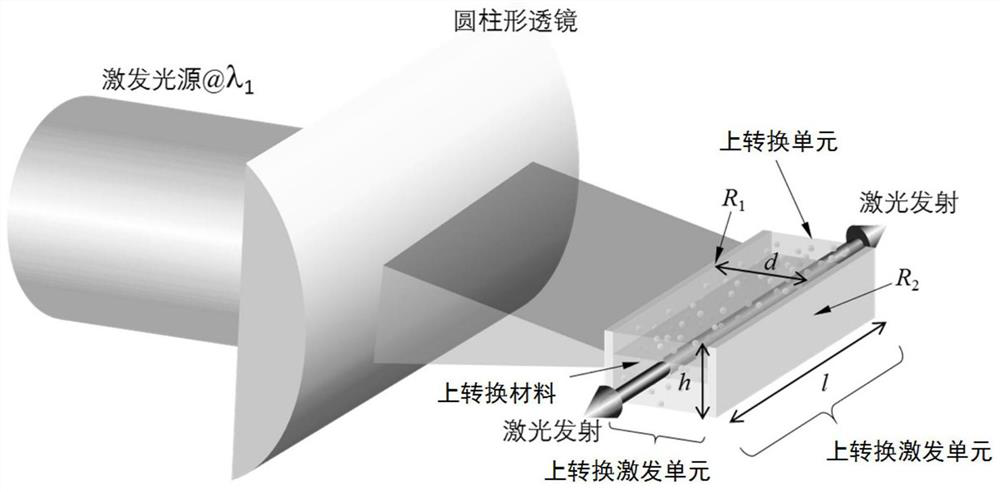

Up-conversion excitation unit and laser thereof

A conversion unit and laser technology, applied in the field of lasers, can solve problems such as low laser efficiency, and achieve the effects of improving laser efficiency, reducing overflow loss, and improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] An up-conversion laser, comprising: a total reflection mirror with a refractive index of 100% and a non-total reflection mirror with a refractive index of 95%, and an up-conversion unit arranged between the total reflection mirror and the non-total reflection mirror; The up-conversion unit consists of 40SiO 2 -13Al 2 o 3 -10Na 2 CO 3 -20BaF 2 -4LaF 3 A glass carrier and an up-conversion material distributed inside the glass carrier, the up-conversion material including Ba 2 LaF 7 Nanocrystalline carrier and Yb doped in nanocrystalline carrier 3+ and Tm 3+ Rare earths; up-conversion materials are precipitated by annealing at 680°C for 1 hour. Among them, compared to Ba 2 LaF 7 , Yb 3+ and Tm 3+ The doping percentage (compared to Ba 2 LaF 7 ) are 90%, 3% respectively. The up-conversion excitation unit is a cuboid, and the vertical distance between the two opposite sides of the total reflection mirror and the non-total reflection mirror varies from more tha...

Embodiment 2

[0053] An up-conversion laser, comprising: a total reflection mirror with a refractive index of 100% and a non-total reflection mirror with a refractive index of 95%, and an up-conversion unit arranged between the total reflection mirror and the non-total reflection mirror; The up-conversion unit consists of 40SiO 2 -13Al 2 o 3 -10Na 2 CO 3 -20BaF 2 -4LaF 3 A glass carrier and an up-conversion material distributed inside the glass carrier, the up-conversion material including Ba 2 LaF 7 Nanocrystalline carrier and Yb doped in nanocrystalline carrier 3+ and Tm 3+ Rare earths; up-conversion materials are precipitated by annealing at 670°C for 1 hour. Among them, compared to Ba 2 LaF 7 , Yb 3+ and Tm 3+ The doping percentage (compared to Ba 2 LaF 7 ) are 90%, 3% respectively. The up-conversion excitation unit is a cuboid, and the vertical distance between the two opposite sides of the total reflection mirror and the non-total reflection mirror varies from more tha...

Embodiment 3

[0055] An up-conversion laser, comprising: a total reflection mirror with a refractive index of 100% and a non-total reflection mirror with a refractive index of 95%, and an up-conversion unit arranged between the total reflection mirror and the non-total reflection mirror; The up-conversion unit consists of 40SiO 2 -13Al 2 o 3 -10Na 2 CO 3 -20BaF 2 -4LaF 3 A glass carrier and an up-conversion material distributed inside the glass carrier, the up-conversion material including Ba 2 LaF 7 Nanocrystalline carrier and Yb doped in nanocrystalline carrier 3+ and Tm 3+ Rare earths; up-conversion materials are precipitated by annealing at 660°C for 1 hour. Among them, compared to Ba 2 LaF 7 , Yb 3+ and Tm 3+ The doping percentage (compared to Ba 2 LaF 7 ) are 90%, 3% respectively. The up-conversion excitation unit is a cuboid, and the vertical distance between the two opposite sides of the total reflection mirror and the non-total reflection mirror varies from more tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com